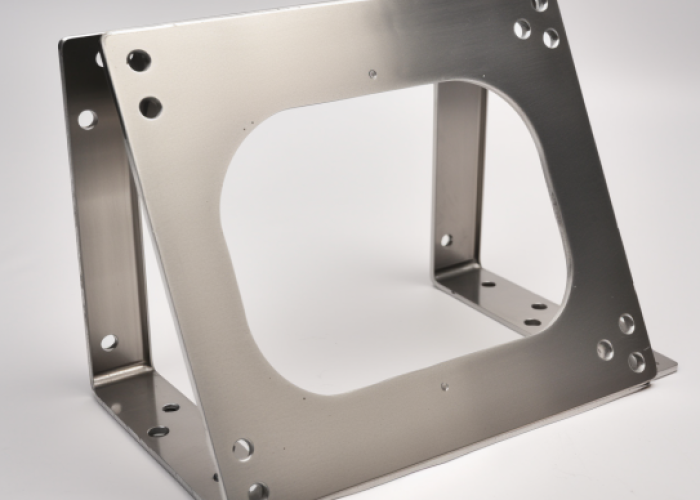

Sheet metal assembly failures often stem from poor design decisions made early in development. With extensive experience manufacturing precision assemblies for aerospace and medical applications, small design adjustments can prevent costly redesigns and production delays.

Successful sheet metal assembly requires uniform thickness, proper bend clearances, tolerance stacking management, and appropriate joining methods. Follow the 4T rule for bend clearances and design folded parts in CAD rather than flat patterns.

Learn key sheet metal tips: thickness limits, bend planning, and assembly trade-offs—plus real-world tolerance strategies from production experience.

Table of Contents

How Do Material-Specific Thickness Limitations Affect Sheet Metal Design?

Material thickness limitations force design compromises in bend radii, tolerance stacking, and part integration. Aluminum offers the widest range (0.024″-0.250″), while stainless steel and brass have restricted standard gauges that may require design modifications.

Key material thickness considerations include:

- Aluminum: 0.024″-0.250″ range, excellent formability, ±0.1 mm typical tolerance

- Stainless Steel: Limited standard gauges, ±0.005″-0.015″ achievable tolerance

- Brass/Copper: Restricted thickness availability, longer sourcing lead times

- Gauge Variations: 16-gauge aluminum (0.062″) vs. steel (0.059″) affects assembly fit

Material-specific formability characteristics determine manufacturing feasibility. Aluminum alloys like 6061-T6 maintain consistent bend radii across thickness ranges, while stainless steel 316 requires minimum bend radii of 1.5x material thickness to prevent cracking. Copper exhibits work hardening during forming, limiting complex bend sequences in thicker gauges above 0.125″.

Design Takeaway: Match material selection to both functional requirements and standard thickness availability early in design. Account for material-specific forming limitations when specifying bend radii and tolerance allocations.

How to Design Bend Sequences That Avoid Manufacturing Conflicts?

Plan bend sequences to prevent tool interference and part collision during press brake operations. Design later bends with adequate clearance from existing flanges and avoid complex geometries that require multiple setups or specialized tooling.

Critical bend sequence considerations:

- Tool Clearance: Maintain 4x material thickness minimum distance between features and bend lines

- Flange Interference: Design flanges to clear press brake back gauge and tooling

- Access Limitations: Ensure tooling can reach all bend locations without obstruction

- Setup Changes: Minimize repositioning by grouping bends by similar angles and radii

Bend sequence conflicts typically occur when designers create parts requiring bends that interfere with previously formed flanges. A common issue involves designing enclosures where the final bend creates a box that cannot accommodate standard press brake tooling. We recommend modeling bend sequences in CAD using bend-order tables to visualize each forming step and identify potential conflicts before fabrication.

Complex parts may require multiple setups or specialized hemming dies, significantly increasing cost and lead time. For example, designing a chassis with inward-facing flanges after outward bends often requires custom tooling or secondary operations that could be avoided through proper sequence planning.

Design Takeaway: Model your bend sequence in CAD with realistic tooling constraints and consult with your fabricator about press brake limitations during design reviews to avoid costly redesigns.

How to Handle Tolerance Stacking in Multi-Part Assemblies?

Account for cumulative tolerances across all assembly components by applying statistical tolerance analysis and incorporating alignment features like slots instead of holes. Critical dimensions should adhere to ±0.005″ standard tolerances to prevent misalignment.

Tolerance stacking management strategies:

- Statistical Analysis: Use root-sum-square calculations instead of worst-case stacking

- Critical Dimensions: Identify hole-to-edge distances and mating surfaces requiring tight control

- Alignment Features: Design slots, tabs, and self-locating features to absorb variation

- Assembly Sequence: Plan assembly order to minimize cumulative error propagation

In our experience with precision assemblies, tolerance stacking failures typically occur at mounting interfaces and sealing surfaces. For medical device enclosures, we’ve found that maintaining ±0.005″ on critical hole-to-edge dimensions while allowing ±0.010″ on non-functional features provides optimal balance between cost and assembly reliability.

Fitment adjustments through “wiggle room” design—such as elongated mounting slots instead of round holes—accommodate minor dimensional variations without compromising structural integrity. This approach proves especially effective in multi-material assemblies where different thermal expansion rates can cause alignment issues over temperature cycles.

Design Takeaway: Reserve tight tolerances for functionally critical dimensions only, and design adjustability into your assembly interfaces to accommodate normal manufacturing variation without affecting performance.

How to Handle Tolerance Stacking in Multi-Part Assemblies?

Account for cumulative tolerances across all assembly components by applying statistical tolerance analysis and incorporating alignment features like slots instead of holes. Critical dimensions should adhere to ±0.005″ standard tolerances to prevent misalignment.

Tolerance stacking management strategies:

- Statistical Analysis: Use root-sum-square calculations instead of worst-case stacking

- Critical Dimensions: Identify hole-to-edge distances and mating surfaces requiring tight control

- Alignment Features: Design slots, tabs, and self-locating features to absorb variation

- Tolerance Allocation: Reserve tight specs for functional interfaces, relax non-critical dimensions

In our experience with precision assemblies, tolerance stacking failures typically occur at mounting interfaces and sealing surfaces. For medical device enclosures, we’ve found that maintaining ±0.005″ on critical hole-to-edge dimensions while allowing ±0.010″ on non-functional features provides optimal balance between cost and assembly reliability.

Fitment adjustments through “wiggle room” design—such as elongated mounting slots instead of round holes—accommodate minor dimensional variations without compromising structural integrity. This approach proves especially effective in multi-material assemblies where different thermal expansion rates can cause alignment issues over temperature cycles.

Design Takeaway: Reserve tight tolerances for functionally critical dimensions only, and design adjustability into your assembly interfaces to accommodate normal manufacturing variation without affecting performance.

When to Use Welding vs. Rivets vs. Bent Tabs for Assembly?

Use welding for permanent high-strength joints, rivets/screws when disassembly is required or heat distortion must be avoided, and bent tabs for low-load applications without additional hardware costs. Selection depends on strength requirements, accessibility, and serviceability needs.

Assembly method selection criteria:

- Welding: Maximum joint strength, permanent assembly, creates heat-affected zones

- Rivets/Screws: Reversible joints, no heat distortion, requires access from both sides

- Bent Tabs: No fasteners needed, cost-effective, limited to light-duty applications

- Load Requirements: Match method to expected stress and fatigue cycles

Welding provides superior joint strength but generates heat-affected zones that can warp thin materials or affect nearby precision features. We recommend avoiding welding within 0.5″ of critical dimensions or tight-tolerance holes. For aerospace applications requiring structural integrity, welded joints offer maximum strength but complicate inspection and repair procedures.

Rivets and threaded fasteners allow field serviceability while minimizing thermal distortion during assembly. These methods prove essential for electronics enclosures requiring periodic access or medical devices needing sterilization compatibility. However, they require clearance for installation tools and add material costs.

Bent tabs eliminate fastener expenses and create clean aesthetic lines but limit future modifications. This approach works well for consumer products where permanent assembly is acceptable and smooth surfaces are desired.

Design Takeaway: Match assembly method to functional requirements—use welding for maximum strength, mechanical fasteners for serviceability, and formed tabs for cost-effective permanent assembly without hardware.

What Design Features Simplify Sheet Metal Assembly?

Self-aligning features like chamfered edges and locating tabs reduce assembly time by 30-40%. Standardize hardware types and design clear orientation cues to streamline production workflow.

Assembly simplification strategies:

- Self-Alignment: Chamfered holes and locating tabs guide proper positioning

- Orientation Cues: Design obvious visual features to prevent incorrect assembly

- Edge Safety: 0.005″-0.010″ radius breaks improve handling and reduce stress

- Snap-Fit Features: Eliminate loose hardware in appropriate applications

From manufacturing thousands of precision assemblies, we’ve found that chamfered holes (0.010″-0.020″ chamfer) reduce fastener installation time by 40% while eliminating cross-threading issues. Locating tabs positioned at part corners eliminate the need for assembly fixtures, particularly valuable for medical device enclosures where consistent gasket positioning is critical.

In audio equipment chassis production, we’ve seen assembly error rates drop from 8% to under 2% when parts include obvious orientation features like asymmetric cutouts or embossed alignment marks. Sharp corners not only create safety hazards but also concentrate stress that can initiate cracks during press brake forming operations.

Design Takeaway: Incorporate self-locating features and safety edges early in design. These manufacturing-driven details significantly improve assembly efficiency and reduce operator training requirements while preventing quality issues.

Conclusion

Sheet metal assembly success depends on early material selection, proper bend sequencing, and tolerance management strategies. Standardizing assembly methods and incorporating self-aligning features reduces production costs while improving reliability. Contact us to explore manufacturing solutions tailored to your sheet metal assembly requirements.

Frequently Asked Questions

Maintain bend radius at least 1x material thickness for aluminum, 1.5x for stainless steel. Keep holes and features at least 4x material thickness away from bend lines to prevent distortion.

No. Reserve ±0.005″ tolerances for critical mating surfaces only. Use ±0.010″ for non-functional dimensions to reduce cost while maintaining assembly fit and quality.

Use welding for permanent high-strength joints where disassembly isn’t required. Choose fasteners when you need field serviceability, access limitations exist, or heat distortion could affect nearby precision features.

Yes, but account for different thermal expansion rates, galvanic corrosion potential, and varying forming characteristics. Use isolation methods like gaskets or coatings at material interfaces when necessary.

Provide native CAD files (.sldprt, .ipt) plus neutral formats (.step, .iges). Include detailed 2D drawings with GD&T callouts for critical dimensions and bend sequence notes.

0.024″ (0.609mm) is the minimum for most applications, but 0.032″ aluminum or 0.030″ stainless steel provide better forming reliability and joint strength for multi-part assemblies requiring durability.