Engineers often receive sheet metal cutting quotes that seem unexpectedly high, unsure which design choices are driving costs. With decades of CNC cutting experience across aerospace, audio, and medical sectors, we’ve seen how specific design decisions can triple manufacturing costs without adding functional value. At Okdor, we help product developers identify and eliminate these cost drivers before production.

Standardizing material thickness, optimizing feature spacing, and selecting appropriate tolerances can reduce sheet metal cutting costs by 40-70%. Primary cost drivers include setup complexity, tool changes, material waste, and processing time. ISO 2768 standards guide efficient tolerance selection for non-critical features.

Discover 6 key design factors that drive cutting costs—plus real production data and CNC-proven strategies to optimize for cost efficiency.

Table of Contents

Does Material Thickness Affect Sheet Metal Cutting Costs?

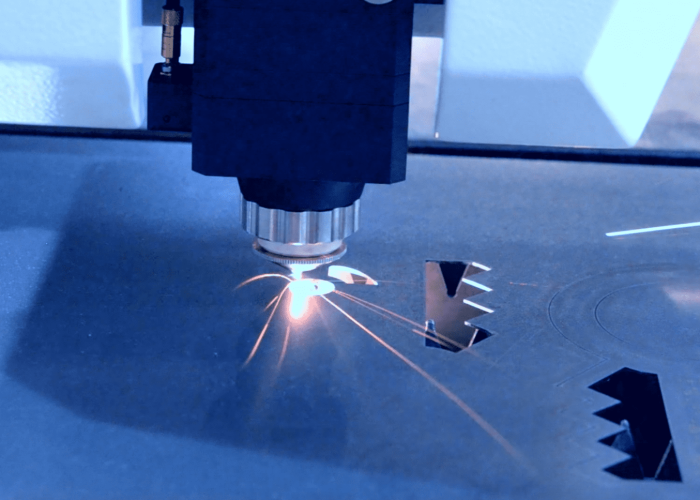

Yes, material thickness significantly impacts cutting costs, with thick materials (above 6mm) increasing costs by 50-150% compared to standard thicknesses. The reason comes down to physics – thicker materials demand slower cutting speeds, higher laser power, and often completely different cutting processes like waterjet instead of laser.

We’ve processed thousands of parts ranging from 0.5mm audio faceplates to 12mm aerospace brackets, and the cost curve isn’t linear. That 3mm aluminum bracket cuts cleanly with our standard laser setup in about 2 minutes. The same bracket in 8mm thickness? It needs waterjet cutting, takes 15 minutes, and costs nearly three times more. The material itself costs more, but the real killer is the processing time and equipment requirements.

Here’s what we see regularly: engineers specify 6mm steel for a medical device housing when 2mm would easily handle the load requirements. That thickness choice alone can double the manufacturing cost because we have to switch from fast laser cutting to slower waterjet processing. Meanwhile, staying in the 0.5-3mm sweet spot keeps you in laser territory where we can hold ±0.1mm tolerances efficiently.

Design Takeaway: Start with the thinnest material that meets your structural needs. Most applications work perfectly with 0.5-3mm thickness, keeping you in the cost-efficient laser cutting range while avoiding the exponential cost increase of thick materials.

What Feature Shapes Are Cheapest to Cut?

Round holes, filleted corners, and rectangular slots with rounded ends are the most cost-effective features to cut in sheet metal. These shapes allow continuous tool movement, eliminate tool changes, and require minimal programming complexity. Complex geometries with sharp internal corners can increase cutting costs by 100-200%.

Round holes dominate cost efficiency because they use standard drill bits or can be cut in single circular movements. We regularly cut 3mm, 5mm, and 8mm holes using pre-staged standard tooling – no setup time between holes of the same size. Compare this to custom oval holes or square holes with sharp corners that require multiple cutting passes or specialized tooling.

Corner design dramatically affects cutting costs. Sharp 90-degree internal corners require EDM finishing or multiple relief cuts, while a simple 1mm radius allows smooth, continuous cutting. An audio equipment chassis we optimized went from 12-minute cutting time with sharp corners to 4 minutes with 1mm radii – identical appearance, 70% cost reduction.

Slot design follows similar rules. Rectangular slots with rounded ends cut efficiently in single passes, while slots with sharp corners require additional operations. The material thickness rule applies here: minimum slot width should equal material thickness to prevent tool deflection and finishing requirements.

Design Takeaway: Choose round holes over complex shapes, add small radii to all internal corners, and design slots with rounded ends. These simple geometry choices eliminate expensive secondary operations while maintaining functionality.

What Spacing Rules Prevent Cutting Problems?

Maintain hole-to-edge distances of at least 2× material thickness and feature-to-feature spacing of at least 3× material thickness to prevent tearing and distortion. Inadequate spacing requires slower cutting speeds, specialized fixtures, or creates scrap parts that increase costs by 40-60%.

Edge distance violations create the most expensive problems. Holes placed 1mm from edges in 2mm material leave insufficient material for structural integrity. The thin web tears during cutting or handling, creating immediate scrap. We’ve seen entire batches rejected because engineers didn’t account for this basic spacing rule – costly lesson that’s easily prevented.

Feature-to-feature spacing prevents material distortion during cutting. When holes or slots sit too close together, the heat from cutting can warp the connecting material, especially in thin sections. A medical device housing we manufactured had 4mm holes spaced 5mm apart – barely enough material between features. Increasing to 12mm spacing eliminated warping issues and allowed normal cutting speeds.

Proper spacing also enables efficient cutting sequences. Well-spaced features allow continuous tool paths without repositioning, while cramped layouts force multiple setups to prevent part movement during cutting.

Design Takeaway: Apply the 2× material thickness rule for edge distances and 3× feature size for spacing between features. This extra material costs minimal but prevents expensive scrap, slow cutting, and specialized fixturing requirements.

Which Corner Design Is Cheapest for Sheet Metal Cutting?

Rounded corners with 0.5-1mm radius are the most cost-effective option, reducing cutting time by 50-70% compared to sharp corners. The physics is straightforward – cutting tools can’t create true sharp internal corners without stopping, backing up, or making relief cuts.

Sharp corners force our laser to completely stop at each 90-degree turn, make a relief cut, then restart. Twelve sharp corners on a bracket? That’s twelve stops and restarts, turning a 3-minute job into 8 minutes. The same part with 1mm radii flows smoothly in one continuous path.

We see this in audio equipment chassis where engineers worry rounded corners look unprofessional. But 0.5mm radii are barely visible while cutting costs in half. One amplifier faceplate went from $45 per piece with sharp corners to $18 with tiny radii – identical appearance, massive production savings.

The toolpath difference is like stop-and-go city driving versus smooth highway cruising. Sharp corners force deceleration, stopping, potential burn marks from dwelling, then acceleration. Rounded corners maintain constant speed with cleaner edges and less heat-affected zone.

External corners matter less for cutting costs but affect durability. Small chamfers prevent stress concentrations that cause cracking under repeated loading.

Simple rule: if you can’t see the radius difference with your naked eye, your customers won’t either, but manufacturing costs drop significantly.

What Tolerances Increase Sheet Metal Cutting Costs?

Tolerances tighter than ±0.1mm significantly increase cutting costs, often requiring secondary machining that doubles part costs. Standard laser cutting achieves ±0.1mm reliably, but anything tighter forces slower speeds, multiple passes, or post-cutting operations that kill your budget.

The tolerance trap catches most engineers eventually. You specify ±0.05mm thinking it’s only slightly tighter than ±0.1mm, but manufacturing-wise, you’ve crossed into expensive territory. That medical device housing needing ±0.025mm hole positions? Laser cutting alone cost $12, then we added $35 for CNC finishing. Relaxing to ±0.08mm eliminated secondary ops with zero functional impact.

Heat creates the real tolerance challenge. Thermal cutting expands material during processing, making consistent tight tolerances tricky without cooling time or post-machining. Aluminum handles this better than steel, but physics still limits what’s achievable in single operations.

Most applications work perfectly with ISO 2768-m general tolerances (±0.1mm for typical features). We’ve seen engineers over-specify tolerances on non-critical dimensions simply because their CAD default was set too tight – expensive habit that adds zero value.

The smart approach: mark only truly critical dimensions with tight tolerances on your drawings. Everything else gets general tolerance callouts, keeping manufacturing simple and costs reasonable while maintaining functionality.

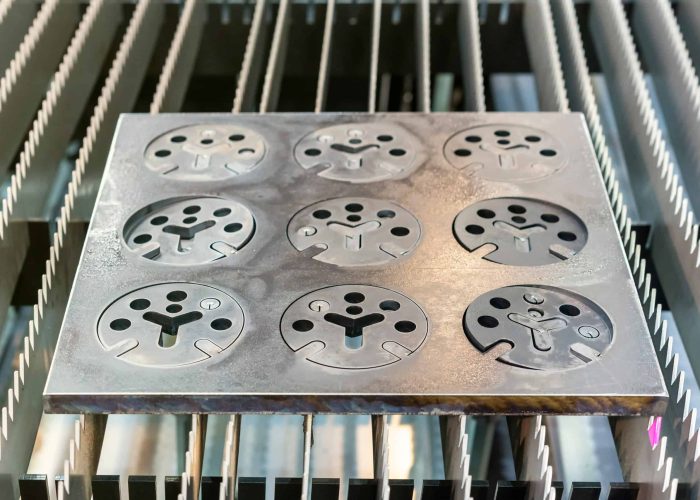

How Does Nesting Affect Sheet Metal Cutting Material Costs?

Efficient part nesting reduces material costs by 30-50% by maximizing sheet utilization and minimizing waste. You pay for the entire sheet regardless of how much you use, so layout efficiency directly impacts your part cost.

Material utilization tells the whole story. A rectangular bracket might achieve 85% efficiency with smart nesting, while poor layouts drop to 40% – literally doubling your material cost per part. The math is brutal when material represents 60% of your total part cost.

We helped an audio manufacturer transform their faceplate production. Original random layout fit 8 parts per sheet at 60% efficiency. Optimized orientation and spacing? Fourteen parts at 90% efficiency – nearly halved their material costs overnight. Same parts, same functionality, dramatically different economics.

Standard sheet sizes matter enormously. Most aluminum and steel comes in 1220×2440mm sheets. Design parts that divide evenly into these dimensions, and nesting becomes much more efficient. A 300×600mm part nests perfectly; a 350×700mm part creates annoying waste strips.

Kerf allowance complicates dense nesting. That 0.3mm laser cut width adds up fast when you’re packing small parts tightly. Sometimes fewer parts with better spacing actually saves material versus cramming everything together.

Work with your supplier on nesting layout before finalizing designs – small dimensional tweaks often unlock major material savings.

Conclusion

Material thickness standardization, feature geometry optimization, and appropriate tolerance selection deliver the largest sheet metal cutting cost reductions without compromising functionality. Focus on 0.5-3mm thickness ranges, rounded corners, and ±0.1mm general tolerances for maximum efficiency. Smart spacing and nesting strategies provide additional 30-50% material savings. Contact us to explore manufacturing solutions tailored to your sheet metal cutting requirements.

Frequently Asked Questions

Placing holes closer than 2× material thickness from edges causes material tearing during cutting or handling. This basic spacing violation creates immediate scrap and forces expensive specialized fixturing or slower cutting speeds.

Poor layouts achieving 40% sheet utilization versus optimized 85% efficiency can double your material costs per part. Work with suppliers on nesting optimization before finalizing part dimensions.

Only on critical fit surfaces where function absolutely requires it. Mark these features clearly on drawings and use ±0.1mm general tolerances everywhere else to control secondary machining costs.

Anything above 6mm typically requires waterjet instead of laser cutting, increasing costs 50-150%. Stay within 0.5-3mm thickness ranges to access efficient laser processing and avoid exponential cost increases.

Yes, when the functional difference is minimal. Standard sizes (3mm, 5mm, 8mm) eliminate tool changes and setup time. A 0.2mm difference in hole diameter rarely affects function but can double machining costs.

Specifying unnecessary tight tolerances (±0.05mm or tighter) on non-critical features. This often doubles part costs by requiring secondary machining operations that standard laser cutting could otherwise handle efficiently at ±0.1mm.