Developing precision enclosures for aerospace, audio, and medical applications requires more than CAD validation—it demands real-world testing with actual materials and manufacturing processes. With decades of experience fabricating prototypes that transition seamlessly to production, understanding the nuances between prototype and production performance can save both time and costly redesigns.

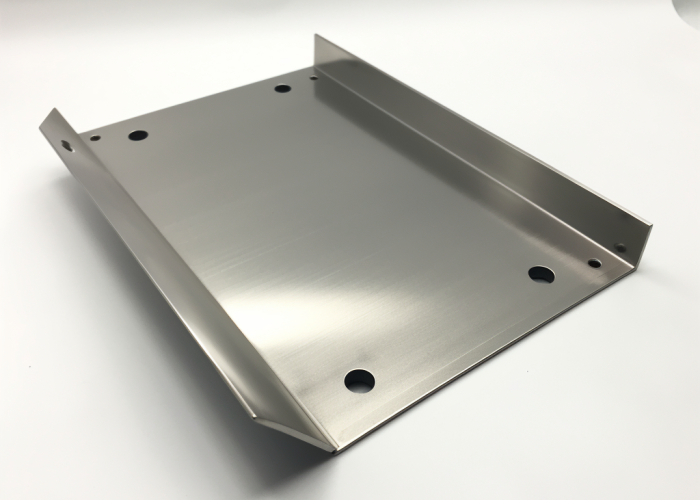

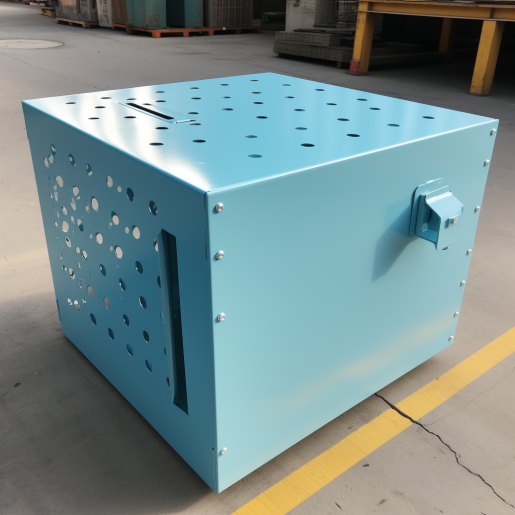

Sheet metal prototyping creates functional test parts using production-grade cutting, bending, and forming processes on metal sheets typically 0.006 to 0.25 inches thick. These prototypes use the same laser cutting, press brake forming, and welding techniques as final production, allowing engineers to validate structural performance, assembly fit, and material behavior before committing to manufacturing volumes.

Learn how to pick materials and thicknesses for reliable prototyping, cut costs and lead times, and avoid accuracy issues—based on real sheet metal work.

Table of Contents

Are sheet metal prototype test results reliable for production?

Sheet metal prototypes achieve 85-95% reliability for production validation when using identical materials and CNC processes, with dimensional accuracy within ±0.01-0.05mm for most applications. Digital image correlation testing on prototypes accurately predicts production failure initiation points, making it particularly valuable for evaluating new materials in aerospace and automotive applications.

Material strength directly impacts reliability—Advanced High-Strength Steel shows 20-40% higher springback in production than prototypes predict, while mild steel and aluminum maintain tighter correlation. Springback variations cause the most significant differences, typically increasing 2-4° in production due to tooling variation. Structural testing with identical materials provides excellent correlation for tensile strength, fatigue life, and thermal behavior.

Surface-dependent properties require separate validation since prototype finishing often differs from production processes. Anodizing thickness, powder coating adhesion, and EMI shielding performance may vary when moving from hand-finishing to automated production lines. According to ISO 2768 testing protocols, correlation improves dramatically using production-equivalent tooling and actual material lot properties.

Design Takeaway: Trust prototype results for structural integrity and assembly fit when using identical materials and processes. Plan for 10-20% higher springback in production, validate surface treatments separately, and test critical dimensions with production-equivalent tooling for ±0.005″ tolerances.

What sheet metal material and thickness work best for prototyping?

6061-T6 aluminum at 0.063″ thickness provides optimal prototyping performance, currently costing $3.60-3.85/lb vs. $4-6/lb for 304 stainless steel, with 2-3 day availability and excellent prototype-to-production correlation. Recent quotes show 6061-T6 at $3.85/lb for larger quantities, up from $2.05/lb a year ago, while maintaining better availability than specialty alloys.

When production parts use expensive materials like titanium, prototype with 6061-T6 aluminum for geometry validation first, then order 2-3 production material samples for final testing. This hybrid approach reduces costs by 70% while maintaining test validity. For medical applications, prototype with 304 stainless instead of 316L initially—both machine similarly, and 304 costs 40% less.

Thickness selection affects springback behavior non-linearly, so match production thickness when dimensional accuracy matters. Standard thicknesses like 0.063″ and 0.090″ aluminum ship faster since suppliers stock them regularly. Most suppliers require 5-7 lb minimums for aluminum, though prototype shops often work with smaller quantities shipped via UPS.

Design Takeaway: Start with 6061-T6 aluminum at 0.063″ for geometry validation—costs less, machines faster, ships quickly. Use production materials only for final validation when material properties matter for testing.

How do I reduce sheet metal prototype cost and lead time?

Use standard bend radii and avoid holes near bends—this eliminates custom tooling requirements and reduces prototype costs 40-60% while cutting lead time from 2 weeks to 2-3 days. Moving holes 0.125″ away from bend lines saves $50-200 per prototype by eliminating custom tooling needs.

Process selection drives cost and timeline. Laser cutting + press brake bending costs $200-500 and ships in 2-3 days. Adding drilling/tapping adds $150-300 and 3-5 days. Complex forming or welding pushes costs to $1000+ with 2-3 week lead times. Single prototypes cost 5-10x per piece compared to runs of 10-25 parts due to setup amortization—order multiple iterations simultaneously for better economics.

Material sourcing affects both cost and speed. Direct aluminum costs $3.60-3.85/lb versus $5-6/lb through fabricators. Standard materials like 6061-T6 ship in 2-3 days while specialty alloys require 1-3 weeks plus larger minimums.

Design Takeaway: Design for standard processes—0.125″ bend radius, holes 3x material thickness from bends, standard thicknesses. This typically saves 50-70% on cost and delivers parts in days instead of weeks.

Can I use production materials in sheet metal prototypes?

Production materials work for prototypes but often require 1-3 weeks lead time and 200-400% higher costs—use material substitution strategies to validate 90% of design issues with faster, cheaper alternatives, then confirm critical properties with actual production materials. Specialty suppliers like Supra Alloys offer titanium products with “relatively short lead time” for prototype quantities.

The practical approach involves using readily available materials for design iteration, then validating with production materials only when material properties affect testing objectives. For medical devices, prototype with 304 stainless for mechanical validation, then test biocompatibility with 316L samples. This hybrid strategy maintains test validity while reducing costs and lead times significantly.

Material properties create substitution challenges—aluminum has 64% of copper’s electrical conductivity while titanium only has 3.1%, making direct substitution impossible for electrical testing applications. Thermal expansion coefficients also vary significantly between materials, affecting precision assemblies where thermal cycling matters.

Specialty suppliers typically stock common grades and source exotic alloys within 1-3 weeks for prototype quantities, though minimum order charges apply. The key involves understanding which properties your specific tests require versus which seem important but don’t affect validation goals.

Design Takeaway: Match material selection to testing objectives rather than final specifications. Use available materials for geometry validation, then validate critical material properties with authentic samples. Lead times are typically 1-3 weeks, not months, but costs increase significantly for small quantities.

Will sheet metal prototypes show assembly and fit problems?

Sheet metal prototypes reveal assembly problems accurately when accounting for process differences—laser-cut prototypes show different edge conditions than stamped production parts, and manual welding creates 2-3x more distortion than production welding fixtures. Understanding these process variations helps interpret prototype results correctly.

Prototypes excel at revealing mechanical interference, hardware accessibility problems, and tolerance accumulation effects that CAD models can’t predict. When testing electronic enclosures, prototypes accurately show whether PCBs fit properly and whether assembly sequences work in practice.

Hand-welded prototype joints produce different distortion patterns than production fixture welding, where controlled sequences minimize warping. Surface finish effects also surprise engineers—anodizing thickness and edge finishing variations affect threaded connections and press-fit assemblies differently than prototype testing predicts.

The most reliable approach involves testing assemblies progressively: before welding to verify basic fit, after welding to understand distortion effects, and with representative surface finishes to validate final assembly characteristics. This reveals which aspects transfer reliably and which require additional verification.

Design Takeaway: Use prototypes to validate mechanical fit, hardware access, and basic assembly sequences while recognizing that welding distortion and surface finish effects may require separate validation. Test critical assemblies through the complete manufacturing sequence.

What design mistakes make sheet metal prototypes inaccurate?

Designing impossible features forces fabricators to modify parts without notification—bend radii smaller than material thickness, holes closer than 3x material thickness to bends, and unsupported overhangs that deflect during forming create prototype inaccuracy. These “silent corrections” invalidate prototype testing for production prediction.

The most dangerous mistake involves creating designs that work as one-offs but fail during production scaling. Prototype shops often accommodate impossible geometries through manual workarounds that won’t exist in production environments. CAD software compounds this by allowing geometrically impossible features without warning.

Standard practice requires bend radii at least equal to material thickness and maintains ±1° tolerance on bend angles, while holes near bends should be positioned appropriately to prevent distortion. When prototype shops make corrections silently, resulting parts don’t reflect production reality.

Materials like stainless steel and high-strength alloys exhibit more springback, requiring compensation in design, while large flat sections may warp due to internal stresses. When prototypes use substitute materials with different forming behavior, springback predictions become unreliable for production.

Design Takeaway: Design for production processes from project start, ensuring prototype methods align with production intentions. Use realistic bend radii, proper hole spacing, and appropriate tolerances. Verify fabricators understand production constraints and avoid silent design modifications.

Conclusion

Sheet metal prototyping succeeds through smart material selection, process alignment, and design validation strategies. Tolerances tighter than ±0.01mm often prove unnecessary, while matching prototype methods to production processes ensures reliable results. Focus on geometry validation first, then material-specific testing. Contact us to explore manufacturing solutions tailored to your sheet metal prototyping requirements.

Frequently Asked Questions

Prototype shops often make silent design corrections—adjusting impossible bend radii, moving holes from bend lines, or modifying geometries. Request fabrication notes showing any design modifications. Design for production constraints from the start: minimum bend radius equals material thickness, holes 3x thickness from bends.

Skip prototyping only for simple parts with proven geometry—basic brackets, flat panels, or parts nearly identical to previous successful designs. Never skip for first assemblies, new materials, tight tolerances under ±0.010″, or customer-facing parts where appearance and feel matter.

Prototype iterations cost $500-2000 per design cycle. Production tooling modifications cost $50,000-200,000 after manufacturing begins. Multiple prototypes reveal tolerance stack-up issues, assembly problems, and manufacturing constraints that prevent expensive production failures and redesign costs.

Test with identical materials for customer-facing features and production processes for critical functions. Include temperature cycling, repeated assembly/disassembly, and actual user scenarios. Document differences between prototype and production processes to communicate changes to stakeholders and predict performance variations.

Titanium prototyping costs $2000 vs. $200 for aluminum, with identical assembly and fit results for geometry validation. Use aluminum for design iteration, then validate material properties with 2-3 titanium samples after design freeze. This approach saves 70% while maintaining validation integrity for aerospace and medical applications.

Prototypes predict performance when using identical materials and processes. Production welding creates different distortion patterns than hand welding, and stamping produces different edge conditions than laser cutting. Test prototypes after each manufacturing step and validate critical dimensions with production-equivalent processes for reliable correlation.