Unprepared CNC designs cause costly delays and quote rejections. After machining parts for aerospace, medical, and audio sectors, we see the same avoidable mistakes that push back timelines and inflate budgets.

A CNC design is production-ready when it passes eight critical checkpoints: appropriate tolerances, adequate wall thickness, standard tooling compatibility, proper hole specifications, size constraints, compatible corner radii, efficient material selection, and complete GD&T documentation.

Learn the specific thresholds for each checkpoint and how small adjustments prevent costly revisions.

Table of Contents

Are your tolerances tighter than functionally required?

Tight tolerances are only needed for features that directly affect assembly, fit, or mechanical function. Most CNC parts need ±0.01 mm precision only on critical features like bearing seats, shaft bores, and threaded holes, while general surfaces can use ±0.05 mm without compromising performance.

The key is distinguishing between functional and non-functional features during design. Features requiring ±0.01 mm include bearing bores (press fits), mating surfaces between assemblies, threaded engagement areas, and seal grooves where leakage is critical. Meanwhile, cosmetic surfaces, clearance holes, internal cavities, and non-mating edges function perfectly at ±0.05 mm tolerances.

We see this decision point repeatedly in faceplate designs: mounting holes and control shaft bores need ±0.01 mm for proper fit, but decorative surfaces and cable routing slots work fine at standard tolerances. The same logic applies to enclosures—sealing surfaces require precision, but internal mounting bosses and cosmetic details don’t.

Quick Decision Framework: Ask these three questions for each feature:

- Does this feature mate with another part? → ±0.01 mm

- Does this feature affect assembly or function? → ±0.01 mm

- Is this decorative or clearance only? → ±0.05 mm

Common ±0.01 mm Features:

- Bearing bores and shaft fits

- Threaded holes (engagement depth critical)

- Sealing surfaces and O-ring grooves

- Pin locations and alignment features

Safe for ±0.05 mm:

- Cosmetic surfaces and edges

- Clearance holes (screws, cables)

- Internal cavities and pockets

- Non-mating external surfaces

For reference, ISO 2768-m general tolerances cover most non-critical dimensions without special callouts, keeping drawings clean and manufacturing straightforward.

Design Takeaway: Use the three-question framework to categorize features during design. Reserve ±0.01 mm tolerances for assembly-critical features only, and apply ±0.05 mm everywhere else to maintain functionality while controlling machining costs.

Can your wall thicknesses handle machining forces?

Aluminum walls thinner than 0.8 mm and plastic walls under 1.5 mm risk deflection, chatter, or breakage during CNC machining. Use this height-to-thickness ratio check: if the wall height divided by thickness exceeds 10:1, the wall needs reinforcement or redesign to prevent machining problems.

Thin walls show visible problems during machining: chatter marks from vibration, dimensional drift as walls deflect away from cutting tools, and in severe cases, cracking or complete failure. We’ve machined 0.5 mm aluminum walls that looked acceptable in CAD but showed significant deflection during cutting, ruining surface finish and making tight tolerances impossible to hold.

The height-to-thickness calculation helps predict problems: a 1.5 mm wall with 15 mm height gives a 10:1 ratio (acceptable), but the same wall at 25 mm height gives 17:1 (problematic). Instead of thickening the entire wall, smart reinforcement options include adding ribs every 30-40 mm, creating stepped thickness transitions, or breaking long spans into shorter sections.

Wall Thickness Reality Check:

- Calculate: Wall height ÷ thickness = should be <10:1

- Material minimums: 0.8 mm aluminum, 1.5 mm plastic, 0.5 mm steel

- Visual problems: Chatter marks, dimensional drift, surface waviness

- Red flags: Ratios above 10:1, sudden thickness changes, large flat areas

Smart Reinforcement Options:

- Add ribs every 30-40 mm instead of doubling wall thickness

- Create stepped transitions rather than uniform thin walls

- Break long spans with internal features or mounting points

- Use gussets at corners to distribute cutting forces

Design Takeaway: Apply the 10:1 height-to-thickness rule during design reviews. When walls fail this test, add strategic reinforcement rather than increasing overall thickness—this saves material cost while solving deflection problems.

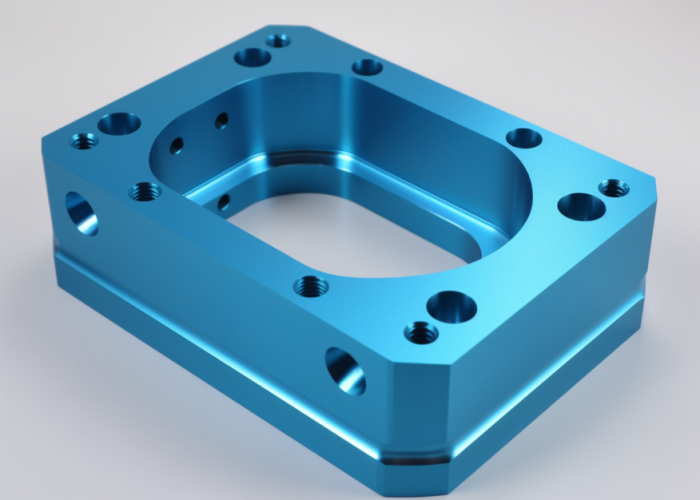

Will standard tooling reach all your features?

Standard CNC tooling can access most features, but problems arise when tool holders can’t fit around geometry or when tools must extend beyond 4x their diameter. Check tool access by ensuring adequate clearance around features—typically 15-20 mm diameter space for tool holder movement.

Tool access failures create expensive problems: features that require custom long tools (which break easily), multiple fixture setups that increase lead time, or alternative processes like EDM that multiply costs. Clearance problems occur when surrounding geometry blocks the space needed for tool holders to operate safely without hitting adjacent walls or features.

Common access problems include deep pockets where tool holders hit walls before cutting starts, internal corners surrounded by tall features, and narrow slots that require long, fragile tools. We frequently see faceplate designs with recessed areas that look simple but need specialized tooling because standard holders can’t clear adjacent raised features.

Tool Access Checklist:

- Clearance check: Ensure 15-20 mm space around features for tool holder movement

- Pocket depth rule: Keep pockets wider than they are deep

- Tool extension limit: Avoid features requiring tools longer than 4x diameter

- Corner access: Internal corners need 3 mm minimum radius for tool clearance

Problem Geometry Red Flags:

- Deep narrow slots (<6 mm wide, >20 mm deep)

- Internal corners with less than 3 mm radius

- Recessed features surrounded by tall walls

- Undercuts requiring specialized tooling (T-slots, dovetails)

Simple Design Fixes:

- Round internal corners to 3 mm minimum radius

- Widen deep pockets to improve width-to-depth ratio

- Lower surrounding walls to improve tool holder clearance

- Relocate features away from geometric obstructions

Design Takeaway: Ensure adequate clearance space around features during design reviews. When features create access problems, modify surrounding geometry or relocate features rather than accepting custom tooling costs and complexity.

Do your holes match standard drill and tap sizes

Specifying non-standard hole sizes can double your machining costs and limit supplier options. Stick to common metric sizes (2.0, 3.0, 4.0, 5.0, 6.0 mm) or imperial sizes (#10, 1/4″, 5/16″, 3/8″) that every shop can drill efficiently with standard tooling.

The cost difference becomes clear in sourcing: a 4.0 mm hole gets quoted at standard rates, while a 4.2 mm hole requires custom operations that inflate pricing. We see this repeatedly when engineers specify hole sizes based on CAD defaults rather than manufacturing reality. Similarly, choosing M3.5 threads instead of standard M3 or M4 creates sourcing headaches and premium pricing.

Standard sizes also improve lead times since shops don’t need to source special tooling or plan custom operations. When you specify uncommon sizes, suppliers either decline to quote or add significant cost premiums to cover the complexity.

Hole Size Verification Method:

- List all hole diameters from your CAD

- Cross-reference with standard charts: Metric (1.5, 2.0, 2.5, 3.0, 4.0, 5.0, 6.0, 8.0 mm) or Imperial (#10, 1/4″, 5/16″, 3/8″)

- Round to nearest standard size when function allows

- Flag custom sizes for cost/sourcing evaluation

Standard Thread Quick Check:

- Common metric threads: M2×0.4, M3×0.5, M4×0.7, M5×0.8, M6×1.0

- Common imperial threads: #10-32, 1/4″-20, 5/16″-18, 3/8″-16

- Avoid exotic combinations: M3.5, M4.5, or non-standard pitches

Design Takeaway: Reference standard drill/tap charts before finalizing any hole specification. When your sizes don’t match standard charts, evaluate whether function truly requires the custom dimension or if rounding to standard saves significant cost.

Can your part fit in typical CNC work envelopes?

Small to medium CNC mills typically handle parts up to 500mm x 400mm x 300mm, while desktop machines are limited to 300mm x 200mm x 150mm. Parts exceeding medium machine capacity face limited supplier options and 2-3x higher costs. Check your part dimensions early and plan assembly strategies for oversized components.

Size constraints create real sourcing problems. Parts that fit only large machines eliminate most suppliers, while parts designed for common medium machines maintain competitive options. Beyond supplier selection, oversized parts require specialized workholding and longer lead times that impact project schedules.

Smart designers work within common envelope limits from the start. Breaking a large enclosure into assemblable sections opens up supplier competition and reduces costs. We’ve helped clients redesign oversized parts into modular assemblies that not only fit standard machines but also improved serviceability and shipping logistics.

Work Envelope Planning Guidelines:

- Desktop machines: 300mm x 200mm x 150mm (limited suppliers)

- Medium machines: 500mm x 400mm x 300mm (most common, competitive pricing)

- Large machines: 1000mm+ (premium pricing, few suppliers)

- Clearance consideration: Subtract 30-50mm from envelope for workholding

Size Optimization Strategies:

- Target medium machine envelopes for competitive sourcing

- Design modular assemblies instead of monolithic parts

- Plan joining methods (bolts, dowels, interlocks) for split designs

- Consider orientation flexibility to optimize fit

Design Takeaway: Check part dimensions against 500mm x 400mm x 300mm medium machine limits. When larger parts are essential, design for splitting or budget for premium suppliers and extended lead times.

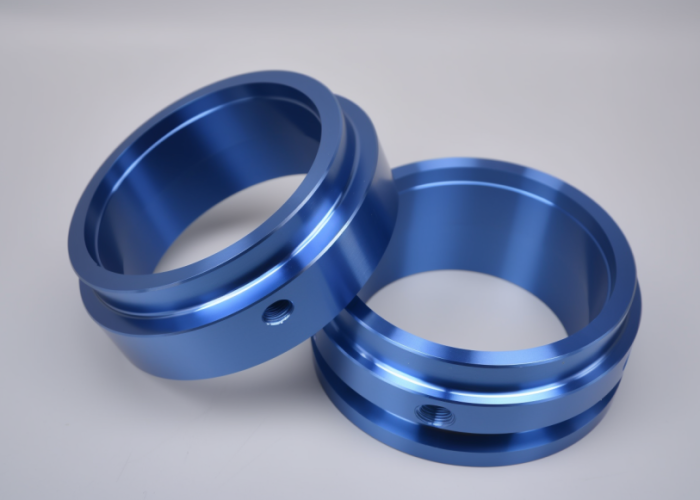

Are your corner radii compatible with cutter sizes?

Sharp internal corners are impossible to machine with standard tools, forcing expensive EDM or specialized operations. Specify corner radii that match standard end mill availability—typically 0.5, 1.0, 1.5, 2.0, 3.0, 4.0 mm—to keep your project within normal CNC pricing.

Radius specification mistakes create sourcing headaches: sharp corners eliminate most suppliers and require premium processes, while odd sizes like 1.3 mm force custom tooling when 1.5 mm would work identically. We regularly help clients reduce quotes by 20-30% simply by adjusting corner specs to match standard tooling availability.

The key insight is understanding that cutting tools are round, so internal corners will always have radii. Your corner radius should roughly equal half the cutting tool diameter. A 2.0 mm end mill creates approximately 1.0 mm radius corners, while a 6.0 mm tool produces roughly 3.0 mm radii.

Corner Radius Decision Framework:

- Identify all internal corners in your design

- Choose from common end mill sizes: 1.0, 2.0, 3.0, 4.0, 6.0, 8.0 mm diameter tools

- Calculate radius: Tool diameter ÷ 2 = approximate corner radius

- Use larger radii for deeper features (better tool access)

Standard Corner Radius Guidelines:

- 0.5 mm radius: 1.0 mm end mill (increases machining time)

- 1.0 mm radius: 2.0 mm end mill (good for shallow features)

- 1.5 mm radius: 3.0 mm end mill (balanced choice)

- 2.0 mm radius: 4.0 mm end mill (robust, cost-effective)

- 3.0+ mm radius: 6.0+ mm end mill (fastest, most economical)

Design Optimization Tips:

- Larger radii enable more robust tooling and faster machining

- Keep radii consistent throughout your design when possible

- Avoid radii smaller than 0.5 mm (manufacturing limitations)

- Consider 1.5-2.0 mm as optimal for most applications

Design Takeaway: Match internal corner radii to available end mill sizes using the tool diameter ÷ 2 relationship. Larger radii enable more robust tooling, faster machining, and lower costs compared to small radii requiring delicate tools.

Did you choose materials that machine efficiently?

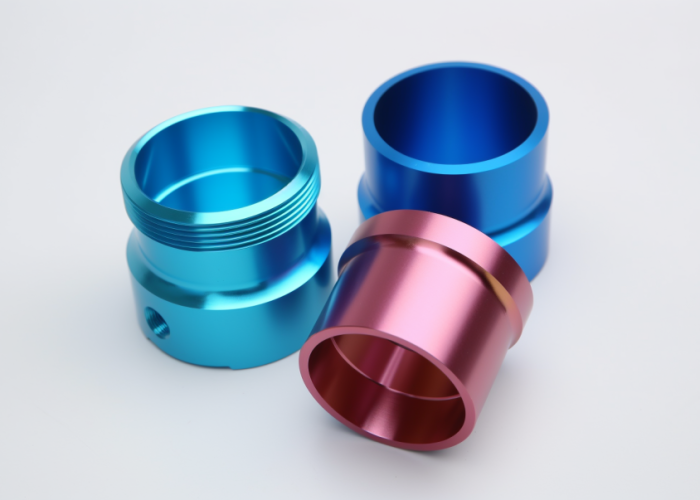

Material selection dramatically affects supplier availability and project costs. Common grades like 6061 aluminum, 304 stainless, and Delrin plastic are stocked everywhere and quoted competitively, while exotic alloys create sourcing bottlenecks and premium pricing. Aluminum machines roughly 4x faster than stainless steel, directly impacting your costs.

The sourcing reality creates stark cost differences: 6061 aluminum gets quotes from every supplier at standard rates, while titanium or Inconel eliminate 80% of potential sources and command 2-3x higher pricing. Even machining speed varies dramatically—aluminum allows fast cutting speeds and long tool life, while stainless steel requires slower speeds and more frequent tool changes.

Smart material selection balances functional requirements with sourcing practicality. We help clients identify when expensive materials are truly necessary versus when common alternatives meet the same performance needs at a fraction of the cost and complexity.

Material Sourcing Categories:

- Widely available: 6061/7075 aluminum, 304 stainless, 1018 steel, Delrin, nylon

- Limited suppliers: 316 stainless, titanium, Inconel, exotic plastics

- Specialty sourcing: Ceramics, composites, medical-grade materials

- Custom order only: Proprietary alloys, non-standard grades

Material Decision Process:

- Define functional requirements: Strength, corrosion, temperature resistance

- List materials meeting requirements

- Check supplier availability for each option

- Compare machining costs (aluminum ~4x faster than stainless)

- Select most available option that meets functional needs

Cost-Smart Material Choices:

- Instead of 316 stainless: Consider 304 with coating if corrosion resistance needed

- Instead of titanium: Evaluate 7075 aluminum for weight-critical applications

- Instead of exotic plastics: Check if PEEK or Delrin meets requirements

Design Takeaway: Start with functional requirements, then choose the most commonly available material that meets your needs. Standard materials offer competitive pricing, faster machining, and broader supplier selection compared to specialty grades.

Do your drawings include complete GD&T specifications?

Incomplete drawings without proper GD&T create costly delays and supplier confusion. Include critical dimensions, tolerances, surface finishes, and material specifications to enable accurate quoting and prevent manufacturing errors. Missing information forces suppliers to make assumptions or request clarification, adding weeks to your timeline.

Documentation problems cascade through the entire sourcing process: vague drawings get declined quotes or inflated pricing to cover uncertainty, while clear specifications enable competitive bidding and faster delivery. We regularly see projects delayed 2-3 weeks simply because suppliers need clarification on tolerances, thread specifications, or surface finish requirements.

The key is providing enough detail for suppliers to quote confidently without over-specifying non-critical features. Complete drawings eliminate back-and-forth clarification cycles and enable suppliers to optimize their processes for your actual requirements rather than guessing at your intent.

Drawing Readiness Test:

- Can a supplier quote without calling you? Check that material grade, critical tolerances, and surface finishes are specified

- Are critical features clearly marked? Distinguish assembly dimensions from general features

- Do thread callouts include depth and class? Specify M6×1.0-6H, 15mm deep instead of just “M6”

- Is surface finish called out where needed? Note Ra 1.6 μm on sealing surfaces, leave others as-machined

Documentation Decision Framework: Start with functional requirements, then specify only what affects performance. Apply tight tolerances (±0.01 mm) to assembly-critical features while using ISO 2768-m for general dimensions. Include material certifications only if required, and specify surface finishes only where they impact function or assembly.

Common Documentation Gaps: Missing material grades (specify 6061-T6, not just “aluminum”), undefined thread engagement depths, no surface finish callouts on critical surfaces, and unclear which dimensions are critical versus reference. These gaps force suppliers to quote conservatively or request clarification.

Design Takeaway: Use the 4-question readiness test before sending drawings to suppliers. Complete documentation enables competitive quoting and faster delivery, while missing specifications create delays and inflated pricing to cover uncertainty.

Conclusion

Avoiding these eight design readiness issues prevents costly revisions, supplier delays, and inflated quotes. Focus on standard specifications, appropriate tolerances, and complete documentation to ensure competitive sourcing and smooth production. Contact us to explore manufacturing solutions tailored to your product requirements—we help optimize designs for cost-effective CNC machining before production begins.

Frequently Asked Questions

If your part exceeds 500×400×300mm, splitting usually reduces costs by opening up more supplier competition. Design simple bolt-together joints or interlocking features. The machining cost savings often outweigh assembly complexity, plus you get easier shipping and serviceability.

Include material grades (6061-T6, not just “aluminum”), specify thread depths (M6×1.0, 15mm deep), call out surface finishes only where needed, and mark which dimensions are critical. If a supplier can’t quote without calling you, your drawings need more detail.

Only when cheaper alternatives can’t meet your functional requirements. Before specifying exotic materials, verify that common options like 6061 aluminum or 304 stainless won’t work. Material choice affects both raw costs and machining speed—aluminum machines 4x faster than stainless steel.

Run these quick checks: Do your holes match standard drill sizes? Are tolerances tighter than ±0.05mm on non-critical features? Does your part exceed 400×300×200mm? Are corner radii smaller than 1.0mm? Do you specify exotic materials? Each “yes” adds cost and limits supplier options.

Common cost drivers include non-standard hole sizes (forcing custom tooling), over-tight tolerances on non-critical features, materials that machine slowly, and parts that don’t fit standard machine envelopes. Most expensive quotes result from specifying custom requirements when standard alternatives would work fine.

Switch to standard hole sizes from drill charts, relax tolerances on non-critical dimensions to ±0.05mm, choose 6061 aluminum over stainless when possible, and increase corner radii to 1.5-2.0mm. These changes often reduce costs 20-40% without affecting performance.