High-speed spur gear applications reveal design challenges that aren’t obvious at lower RPMs—vibration amplification, thermal growth, and dynamic loading that can destroy even well-machined gears. Understanding these physical limits during the design phase prevents costly redesigns when prototypes fail under speed testing or field conditions.

Spur gears can handle high-speed applications up to approximately 3,000-4,000 RPM with proper design, but performance degrades rapidly beyond this range due to noise, vibration, and dynamic loading. Most high-speed applications above 5,000 RPM benefit from helical gears, which distribute loads more smoothly and operate with significantly less noise.

Learn what limits spur gear speed, when designs fail at high RPMs, and how materials and machining precision affect safe performance—based on real examples.

Table of Contents

What design factors limit spur gear speed capability?

Pitch line velocity is the primary speed-limiting factor for spur gears, with AGMA standards specifying limits below 5,000 feet per minute (25 m/s) for enclosed gear drives. Practical speed limits for spur gears reach approximately 6,000 RPM, beyond which noise, vibration, and dynamic loading create reliability issues.

For most industrial applications, 1.5-3 module gears handle speeds up to 3,000 RPM cost-effectively. Smaller modules allow higher RPMs but create weaker tooth sections. Larger modules reach velocity limits faster due to increased pitch diameter.

Tooth profile accuracy becomes critical above 3,000 RPM. Precision grades add 40-60% to costs compared to standard tolerances. Steel offers better high-speed performance than aluminum but costs significantly more in material.

Quick Decision Check: Calculate pitch line velocity (π × pitch diameter × RPM ÷ 60). If approaching 25 m/s or 6,000 RPM, consider helical alternatives before over-specifying spur gear accuracy.

Design Takeaway: Reserve tight tolerances for critical features only. Switch to helical gears when approaching speed limits rather than over-engineering spur gear specifications, which prevents costly redesigns during prototyping.

When does speed make spur gears a bad choice?

Spur gears become problematic above 6,000 RPM due to excessive noise and vibration that no amount of machining precision can eliminate. At these speeds, even perfectly machined gears will generate noise levels that exceed most application requirements and experience dynamic loading that causes premature failure.

For spur and helical gears, the practical speed limit is 6,000 rpm due to fundamental physics, not manufacturing quality. Impact loading from instantaneous tooth engagement creates stress spikes that multiply beyond static calculations. We’ve machined 2 module steel spur gears to ±0.01 mm tolerance that still failed within 500 hours at 5,000 RPM when identical parts run reliably for years at 2,000 RPM.

Specifying tighter tolerances won’t solve high-speed problems. Moving from Class 6 to Class 8 accuracy typically adds 40-60% to machining cost but only reduces noise by 2-3 dB at high speeds. The fundamental mesh characteristics remain unchanged—you’re paying premium prices for minimal improvement.

Heat generation becomes unmanageable above 4,000 RPM regardless of surface finish. Ra 0.8 μm finishes help initially, but sliding friction at tooth tips creates localized hot spots that cause scoring within weeks of operation.

Quick Decision Criteria:

- Speed > 6,000 RPM: Spur gears fail regardless of accuracy

- Noise spec < 70 dB: noise levels up to 55-65 dB are acceptable for spur gears

- Class 8+ accuracy required: Over-specifying won’t solve physics problems

- Heat generation visible: Above 4,000 RPM creates unmanageable hot spots

Design Takeaway: Don’t over-specify spur gear precision for high-speed applications. If your application exceeds 4,000 RPM, switch to helical gears rather than paying for Class 8+ accuracy that won’t solve the underlying physics problems.

When should I switch from spur to helical for high RPM?

Switch to helical gears when approaching 4,000 RPM or when noise must stay below 70 dB. Helical gears cost 30-40% more to machine due to angled cuts and specialized fixturing, but this premium is justified by 15-20 dB noise reduction and significantly longer service life at high speeds.

At 3000-5000 RPM, helical gears show a 15-20 dB improvement over spur gears through gradual tooth engagement. This typically adds 1-2 days to setup time and increases manufacturing costs by 30-40% due to compound angles, longer cycle times, and often 4th-axis machining requirements.

From a manufacturing perspective, helical gears are actually more forgiving at high speeds. The gradual engagement distributes machining imperfections across multiple teeth, while spur gears amplify any geometric errors into noise and vibration issues. The only significant difference in per piece cost is the set-up for helical otherwise it’s about a wash given material, tooth count, etc.

Consider the total specification cost: achieving quiet operation with spur gears above 3,500 RPM often requires Class 9-10 accuracy, custom balancing, and Ra 0.4 μm surface finishes. These specifications can double machining costs compared to standard helical gears that naturally run quieter.

Decision Matrix:

- < 3,000 RPM: Spur gears acceptable, cost 20-35% less than helical equivalents

- 3,000-4,000 RPM: Evaluate noise requirements and total system cost

- > 4,000 RPM: Choose helical for 15-20 dB improvement

Go/No-Go Criteria:

- Immediate helical choice: Noise spec < 70 dB, speed > 4,000 RPM

- Cost analysis needed: Consider bearings, maintenance, and downtime over 3-5 years

Design Takeaway: For applications above 4,000 RPM, specify helical gears with standard Class 6-7 accuracy rather than over-engineering spur gears to Class 8+. You’ll get better performance at lower total manufacturing cost while avoiding specification-driven failures.

What materials work best for high-speed spur gears?

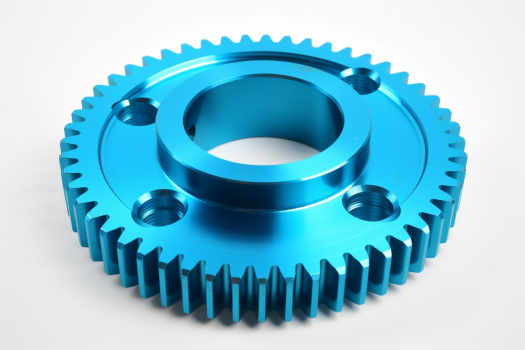

Steel provides the best high-speed performance for spur gears, offering superior dimensional stability under centrifugal forces. While aluminum machines faster with standard tooling and costs less initially, steel gears deliver significantly longer service life at speeds above 3,000 RPM when continuous operation is required.

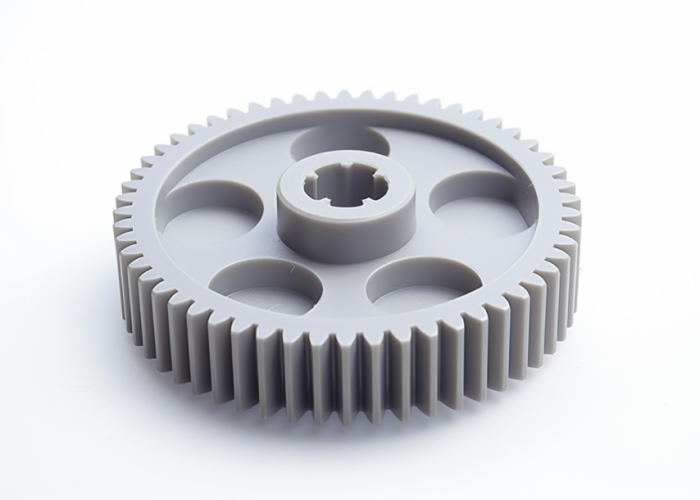

Common aluminum alloys for spur gear production include 2024, 6061, and 7075. For CNC machining, 6061 offers excellent machinability with minimal tool wear and standard cutting speeds. 7075 requires slower feed rates and more robust tooling, increasing setup complexity and cycle times.

7075 typically commanding a 30-50% premium over 6061 in material cost, but aluminum’s superior machinability often provides better total manufacturing cost for prototypes and low-volume production.

Steel requires carbide tooling and controlled feeds but machines to tighter tolerances consistently. Aluminum machines with standard HSS tooling but may need additional finishing passes for precision applications.

Material Decision Framework:

- Steel: Continuous operation >4,000 RPM, production volumes >100 pieces

- 7075 Aluminum: Weight-critical applications, aerospace specifications

- 6061 Aluminum: Prototypes, cost-sensitive projects, <2,000 RPM service

Go/No-Go Criteria:

- Choose steel when: Duty cycle >40 hrs/week or replacement cost exceeds material premium

- Choose aluminum when: Weight specifications exist or machining time drives total cost

Design Takeaway: Base material selection on duty cycle and volume rather than peak performance specs. Steel justifies higher machining cost for production applications, aluminum optimizes cost for development and low-duty applications.

Using spur gears at high speed?

We machine for RPM, clearance, and noise • Evaluate if your spec is production-ready

What gear accuracy grade do I need for high-speed spur gears?

AGMA Class 7 accuracy handles most high-speed spur gear applications up to 4,000 RPM effectively. Class 8-9 requires grinding operations, specialized equipment, and extended lead times while providing minimal performance improvement unless noise specifications demand it.

Class 8+ accuracy often requires post-heat-treat grinding, which limits supplier options to shops with gear grinding capabilities. This extends delivery by 2-3 weeks and increases quotes by 40-60% due to additional operations and inspection requirements.

Most CNC shops can achieve Class 6-7 accuracy with standard hobbing or milling operations using existing equipment. Class 8+ typically requires dedicated gear shops with climate-controlled environments and CMM verification capabilities.

The specification cost cascade: Class 8 gears often require matched shaft tolerances (±0.005 mm runout) and precision bearings, multiplying system cost well beyond the gear manufacturing premium.

Accuracy Decision Matrix:

- Class 6: General industrial, cost-driven projects (<3,000 RPM)

- Class 7: Standard high-speed applications, broad supplier base (3,000-5,000 RPM)

- Class 8+: Audio equipment, medical devices, noise specs <65 dB

Supplier Reality Check:

- Class 6-7: Available from 80% of CNC gear shops, 2-3 week delivery

- Class 8+: Limited to specialized gear shops, 4-6 week delivery, higher quotes

Design Takeaway: Specify Class 7 unless noise testing proves Class 8 necessary. Over-specifying accuracy limits supplier options and increases cost more than performance improves. Focus precision budget on mounting and shaft quality instead.

How does face width affect high-speed spur gear life?

Optimal face width follows the 10x module rule for manufacturing efficiency, with 2.5x tooth height minimum to prevent root failure. Exceeding 12x module creates machining challenges—longer cycle times, tool deflection, and alignment sensitivity—without proportional strength gains.

For metric spur gears, the recommended face width is equal to ten times the module and minimum recommended face width for a spur gear is 2.5 times the tooth height to prevent premature cracking under dynamic loading.

Manufacturing impact increases exponentially beyond 12x module. Tool deflection during long cuts creates taper, requiring multiple roughing passes and finish operations. Setup complexity and cycle time often double when face width exceeds practical tooling limits.

For most industrial applications, a face width-to-pitch diameter ratio of 0.5-1.5 provides the best performance balance. Wider ratios amplify housing alignment errors and create edge loading that reduces actual contact area.

Face Width Manufacturing Guidelines:

- 2.5x tooth height: Minimum to prevent root failure

- 8-10x module: Optimal manufacturing efficiency, standard tooling

- 12x module: Maximum before tool deflection issues

- 15x module: Practical upper limit, requires specialized fixturing

Machining Reality Check:

- <10x module: Single roughing pass, standard setup, 2-week delivery

- >12x module: Multiple passes, custom fixturing, extended delivery

Design Takeaway: Stay within 8-12x module range for optimal manufacturing cost and delivery. Address insufficient load capacity through material upgrades or gear type changes rather than oversizing face width, which creates more problems than it solves.

What shaft and housing tolerances prevent high-speed gear failure?

Shaft runout below 0.025 mm prevents high-speed gear failure more effectively than tight housing tolerances. Engineers commonly over-specify housing concentricity to 0.01 mm while accepting 0.05 mm shaft runout—a costly specification mistake that causes bearing failure within 1,000 operating hours despite expensive housing precision.

For higher RPM machines (more than 3600 RPM), a tolerance of 0.001″ (1 mil or thou) should be used for shaft runout (≈0.025 mm). Poor shaft quality at 4,000 RPM creates vibration that destroys bearings regardless of housing precision, leading to product returns.

Real consequence: 0.05 mm shaft runout causes edge loading that wears gears 3x faster than designed, while 0.01 mm housing concentricity provides no protection. Engineers waste $200-500 per housing on unnecessary precision while allowing shaft defects that cause failures.

Most coaxial requirements can be met with either a position tolerance at MMC or a runout tolerance at RFS, with runout providing identical performance at 30% lower cost than concentricity callouts.

Quick Decision Framework:

- Speed >3,000 RPM: Shaft precision becomes reliability-critical

- Shaft runout <0.025 mm: Prevents bearing failure, extends product life

- Housing bore 0.05 mm: Adequate for 5,000+ hour operation

Red Flags:

- Housing tolerance tighter than shaft: Backwards priority = guaranteed failure

- Concentricity callout: Use runout instead for 30% cost savings

- Poor shaft + tight housing: Bearing failure within 1,000 hours despite high cost

Design Takeaway: Prioritize shaft precision over housing precision to prevent field failures. Reversed priorities waste budget while guaranteeing the bearing and gear failures they’re designed to prevent.

How does backlash affect spur gear performance at speed?

Proper backlash between 0.05-0.10 mm prevents binding while maintaining reliable operation. Zero backlash specifications cause thermal binding during operation, leading to product jamming and customer returns, while controlled backlash provides equivalent positioning performance with reliable operation across temperature ranges.

Backlash accommodates the natural expansion and contraction of metal parts due to temperature changes. This prevents binding and wear. Zero backlash causes seized gears when temperature rises 15-20°C during operation, creating field failures.

Product impact: zero backlash in continuous rotation causes binding that users perceive as “product breaking.” Meanwhile, 0.08 mm backlash provides smooth operation across -10°C to +60°C without affecting user experience.

For standard industrial gearboxes, backlash is typically between 0.05 to 0.20 mm for reliable operation. Too little can lead to gear teeth clashing, creating premature wear, noise, and potential failure.

Quick Specification Guide:

- Servo positioning: 0.05 mm maximum when accuracy affects user interface

- Continuous rotation: 0.08-0.10 mm prevents binding without performance impact

- Temperature range >30°C: Add 0.03 mm for thermal expansion

Prototype Testing:

- Dial indicator check: 0.08 mm = 3-4 divisions on 0.001″ indicator

- Temperature test: Verify operation from -10°C to +60°C operating range

- Binding check: Zero backlash fails when temperature exceeds +20°C from ambient

Design Takeaway: Specify backlash to prevent binding failures rather than chasing theoretical precision. Zero backlash creates temperature-related product failures that controlled backlash eliminates while maintaining equivalent user performance.

What surface finish reduces high-speed spur gear noise?

Ra 0.8-1.6 μm surface finish provides optimal noise reduction for high-speed spur gears while avoiding excessive manufacturing costs. Engineers often over-specify Ra 0.4 μm finishes that significantly increase machining costs without proportional noise improvement, while standard Ra 3.2 μm finishes create unnecessary noise problems above 2,500 RPM.

Improving the surface finish of gear teeth reduces friction and noise during gear meshing. Smooth gear surfaces result in better contact and minimize vibration and noise. However, improvement of the teeth surface finish will lead to much higher costs, which can be more than half of the price of the device.

Smart specification approach balances noise reduction with cost reality. Ra 0.8 μm achieves significant noise reduction compared to standard finishes while remaining achievable with conventional CNC operations. Moving to Ra 0.4 μm requires grinding operations that extend delivery and increase cost substantially.

For critical applications, consider using precision-ground gears with a surface finish of Ra 0.4 μm or better, but only when noise specifications justify the expense.

Surface Finish Guidelines:

- Ra 1.6-3.2 μm: Standard CNC machining, adequate for <2,500 RPM

- Ra 0.8-1.6 μm: Optimal cost/noise balance for high-speed applications

- Ra 0.4 μm: Only when noise specs demand it, requires grinding operations

Quick Decision Check:

- Noise spec >70 dB: Ra 1.6 μm adequate, standard machining cost

- Noise spec <65 dB: Ra 0.8 μm required, verify supplier grinding capability

- Noise spec <60 dB: Ra 0.4 μm necessary, expect doubled finishing costs

Specification Strategy: Target Ra 0.8-1.6 μm for high-speed applications to achieve meaningful noise reduction without excessive manufacturing complexity. Reserve ultra-fine finishes for applications where noise specifications justify the substantial cost increase.

Are high-speed spur gears more cost-effective than helical?

Spur gears cost 20-30% less to manufacture than helical gears, but this advantage disappears above 3,500 RPM when noise and reliability problems force expensive redesigns or component upgrades. Total system cost analysis shows helical gears often provide better value for high-speed applications despite higher initial manufacturing cost.

The only significant difference in per piece cost is the set-up for helical otherwise it’s about a wash given material, tooth count, etc. However, helical gears require specialized angled tooling but deliver smoother operation with setup complexity.

Cost trap reality: engineers choose spur gears to save 25% on gear cost, then spend more on noise dampening, oversized bearings, and frequent maintenance. Meanwhile, helical gears eliminate these secondary costs while providing reliable operation.

From a manufacturing perspective, helical gears are tougher than spur gears. The helix angles are quite hard to replicate with a low acceptable tolerance range, but this prevents field problems that occur with spur gears at high speeds.

Speed-Based Cost Framework:

- <2,500 RPM: Spur gears typically more cost-effective, simpler manufacturing

- 2,500-3,500 RPM: Evaluate total system cost including noise mitigation

- >3,500 RPM: Helical gears usually provide better value despite higher gear cost

Hidden Cost Reality:

- Spur gear penalties: Noise dampening, oversized bearings, frequent replacement

- Helical gear benefits: Longer service life, reduced maintenance, reliable operation

Cost Decision Strategy: Evaluate total system cost rather than just gear manufacturing cost. Spur gears save money initially but often cost more long-term through secondary expenses that helical gears eliminate.

Conclusion

Successful high-speed spur gear design prioritizes shaft precision over housing tolerances, balances surface finish with cost, and evaluates total system cost rather than just gear manufacturing price. Smart specification prevents costly redesigns while ensuring reliable performance.

Contact us to explore manufacturing solutions tailored to your high-speed spur gear requirements.

Choosing the right heat treatment?

We match process to tolerance & lead time • Get treatment + machining advice

Frequently Asked Questions

Specify standard AGMA tooth profiles, use runout instead of concentricity callouts, and avoid Class 8+ accuracy unless testing proves necessity. These choices expand supplier options and reduce delivery time by 2-3 weeks compared to exotic specifications.

Start with spur gear prototypes for speeds below 3,000 RPM to validate basic functionality at lower cost. Switch to helical prototypes when noise testing reveals levels above 70 dB or when speed testing approaches 4,000 RPM, as spur gear limitations become apparent during validation phases.

Before redesigning gears, verify shaft runout is below 0.025 mm and check mounting alignment. Often noise issues stem from poor mounting rather than gear design. If gears are the problem, improving surface finish to Ra 0.8 μm costs less than switching to helical gears.

Test prototypes at 110% of maximum operating speed for 100 hours. If no premature wear or excessive noise occurs with standard tolerances, precision specs aren’t needed. Reserve tight tolerances for applications where testing reveals actual performance issues, not theoretical concerns.

For duty cycles below 20 hours/week, aluminum saves 40% on material cost with adequate performance. Above 40 hours/week continuous operation, steel justifies higher cost through extended service life. Consider total replacement cost, not just initial material expense.

Use a standard dial indicator with magnetic base. Mount indicator against gear tooth, engage gears without load, and rock input gear by hand. Reading should match your 0.05-0.10 mm specification. Test through full temperature range to ensure no binding occurs during thermal cycling.