Selecting 304 stainless steel for CNC projects requires understanding its application limits and machining characteristics. With decades of experience manufacturing precision parts for aerospace, medical, and industrial clients, small material decisions significantly impact both performance and cost.

304 stainless steel contains 17.5-19.5% chromium and 8.0-10.5% nickel, making it the most widely used austenitic stainless steel grade. It offers excellent corrosion resistance, formability, and FDA compliance for food-contact applications while maintaining cost-effectiveness for precision CNC machining.

Learn FDA rules, heat treatment needs, and 304 vs 316 tips—plus real CNC insights to help you meet tolerances and optimize stainless steel designs.

Table of Contents

Can I Use 304 Stainless Steel for Food Contact Applications?

Yes, 304 stainless steel is FDA-approved for direct food contact and meets NSF/ANSI 51 standards for commercial food equipment. Its non-reactive surface resists acids, alkaline cleaning solutions, and maintains hygienic properties essential for food processing applications. The 304 stainless steel we machine meets FDA food-grade specifications for direct food contact use.

Food Safety Compliance:

- FDA 21 CFR 177.2600 approved for direct food contact surfaces

- NSF/ANSI 51 certified for commercial food processing equipment

- Non-reactive to organic acids and food-grade cleaning chemicals

- Maintains surface integrity through repeated sanitization cycles

Food processing equipment commonly uses 304 stainless steel for mixing tanks, conveyor components, and equipment housings. The material maintains corrosion resistance through repeated cleaning cycles with standard food-grade sanitizers. For high-salt environments or frequent bleach cleaning, consider 316 stainless steel for better chloride resistance.

Design Takeaway: 304 stainless steel works for most food contact applications. The material we machine meets FDA food-grade requirements, ensuring your parts are suitable for direct food contact use.

Is 304 Stainless Steel Strong Enough for Load-Bearing Parts?

Yes, 304 stainless steel handles most structural loads with 205 MPa yield strength and 515 MPa tensile strength. These values exceed mild steel (250 MPa typical) while providing superior corrosion resistance. The austenitic structure offers excellent toughness, preventing brittle failure under overload conditions.

Key Strength Specifications:

- Yield strength: 205 MPa (29,700 psi) minimum

- Tensile strength: 515 MPa (74,700 psi) minimum

- Elongation: 40% minimum for excellent ductility

- Excellent fatigue resistance for cyclic loading

- High impact toughness prevents sudden failure

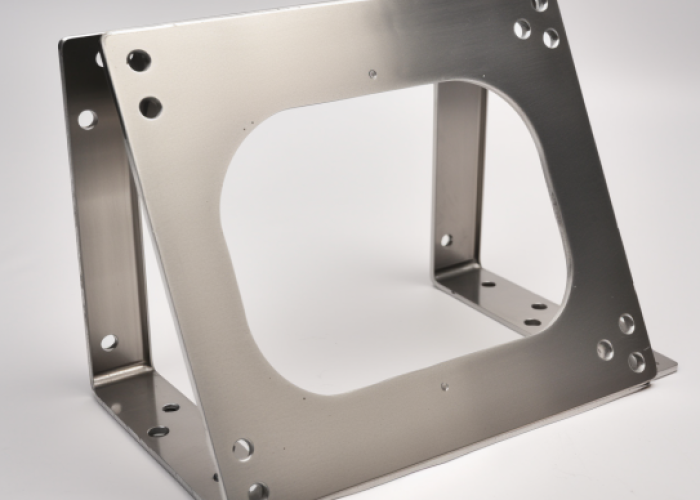

Equipment frames, mounting brackets, and structural housings commonly use 304 stainless steel across aerospace, medical, and industrial applications. Calculate your maximum stress: Load ÷ Cross-sectional area. If under 140 MPa (with 1.5 safety factor), 304 works reliably. The material’s ductility provides additional safety margin against overload conditions, making it ideal for critical structural components.

For high-stress applications requiring strength above 515 MPa, consider precipitation-hardening grades like 17-4 PH stainless steel, which can achieve 1000+ MPa after heat treatment. However, most structural applications find 304’s strength-to-cost ratio optimal for long-term performance.

Design Takeaway: 304 works for most structural applications. Calculate stress levels against 140 MPa working limit. Only specify higher-strength alloys when loads consistently exceed this threshold.

Does 304 Stainless Steel Require Heat Treatment After Machining?

No, 304 stainless steel does not require heat treatment after machining for most applications. Unlike martensitic grades, 304 cannot be hardened and is used as-machined. Stress relief at 400-450°C is optional for precision parts with tight tolerances.

Post-Machining Treatment Options:

- Standard practice: Use as-machined condition

- Optional stress relief: 400-450°C for 1-2 hours

- Improves dimensional stability over time

- Reduces machining-induced residual stress

- Cost impact: Adds 1-2 days lead time and ~15% to part cost

Heavy machining operations like deep milling or high-speed cutting can introduce residual stresses that may cause minor dimensional changes over months or years. For precision components with tolerances tighter than ±0.02 mm, stress relief eliminates these stresses without affecting material properties. This treatment is particularly beneficial for parts subject to temperature cycling or long-term dimensional stability requirements.

Most structural components like brackets, housings, and frames perform reliably without post-machining treatment. The as-machined condition provides full strength and corrosion resistance. Consider stress relief primarily for precision instrumentation, optical mounts, or gauge blocks where dimensional drift could affect performance.

Design Takeaway: Skip heat treatment for standard parts. Consider stress relief only for tolerances tighter than ±0.02 mm or parts requiring long-term dimensional stability.

Is 304 or 316 Stainless Steel Better for Precision CNC Parts?

304 stainless steel machines easier for precision parts due to better machinability and less work hardening compared to 316. Both achieve tight tolerances, but 304 cuts faster with longer tool life, reducing production costs while maintaining quality.

Precision Machining Performance Comparison:

- 304: Superior machinability rating, faster cutting speeds

- 316: Higher work hardening rate, requires careful parameters

- Both achieve ±0.005 mm tolerances with proper setup

- 304: 20-30% lower machining costs for equivalent precision

- Quick decision: Indoor/mild environment = 304. Marine/chemical/high-chloride = 316.

The molybdenum content in 316 that improves corrosion resistance also increases work hardening during cutting, requiring slower speeds and more frequent tool changes. This translates to higher production costs for the same tolerance levels. 304’s superior machinability allows faster cycling without sacrificing precision, making it ideal for high-volume precision work.

Choose 304 for precision components like instrument housings, medical device parts, and optical mounts when environmental conditions permit. Reserve 316 for marine environments, chemical processing, or applications with chloride exposure where the enhanced corrosion resistance justifies the additional machining complexity and cost.

Design Takeaway: Default to 304 for precision work unless your application involves marine, chemical, or high-chloride environments requiring 316’s enhanced corrosion resistance.

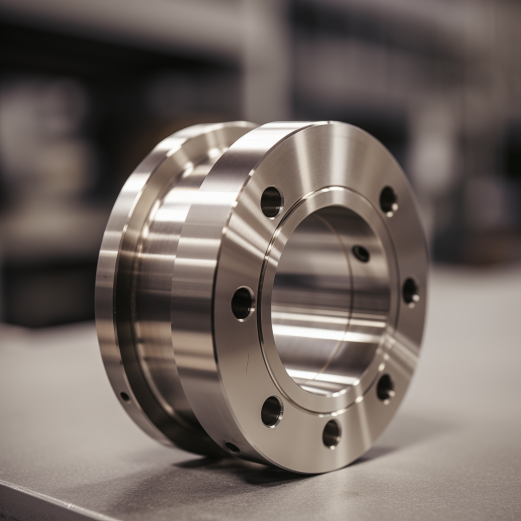

What Tolerances Can 304 Stainless Steel Hold in CNC Machining?

304 stainless steel can achieve tolerances of ±0.005 mm (±0.0002″) for most features with proper machining setup and fixturing. Tighter tolerances to ±0.002 mm are possible for critical dimensions using precision equipment and controlled environments. Work hardening characteristics require careful parameter selection to maintain dimensional accuracy throughout the cutting process.

Achievable Tolerance Ranges:

- Standard features: ±0.005 mm (±0.0002″) typical

- Precision features: ±0.002 mm (±0.00008″) achievable

- Hole diameters: ±0.003 mm with reaming operations

- Surface flatness: 0.005 mm across 100 mm spans

- Concentricity: ±0.002 mm with proper workholding

The austenitic structure of 304 allows excellent dimensional stability once machined, but work hardening during cutting can affect final dimensions if parameters aren’t optimized. Use sharp carbide tools with positive rake angles and maintain consistent feed rates to minimize work hardening effects. Proper fixturing eliminates deflection that could compromise tolerance achievement on thin-walled or complex geometries.

For tolerances tighter than ±0.002 mm, consider finish operations like grinding or EDM. Temperature-controlled machining environments help maintain consistent dimensions, especially for longer production runs where thermal expansion could affect measurements.

Design Takeaway: Specify ±0.005 mm for standard CNC features. Reserve tighter tolerances for truly critical dimensions, as costs increase significantly below ±0.002 mm capability.

The alloy’s composition prevents reactions with acidic or alkaline substances, ensuring that instruments and equipment maintain their integrity. In the food industry, its non-reactive nature and thermal properties make Stainless Steel 304 an excellent choice for food processing equipment, maintaining hygiene standards and ensuring the safety of food products.

What Surface Finish Can You Achieve with CNC Machined 304?

CNC machined 304 stainless steel typically achieves Ra 1.6 μm (63 μin) surface finish as-machined, with Ra 0.4 μm (16 μin) possible using finish passes and proper tooling. The austenitic structure machines to smooth finishes when cutting parameters are optimized to prevent work hardening and built-up edge formation.

Surface Finish Capabilities:

- As-machined: Ra 1.6 μm (63 μin) typical

- Finish machined: Ra 0.4 μm (16 μin) achievable

- Ground finish: Ra 0.1 μm (4 μin) for critical surfaces

- Polished finish: Ra 0.025 μm (1 μin) mirror-like

- Bead blasted: Ra 3.2 μm (125 μin) uniform matte

Sharp carbide tools with polished cutting edges produce the best surface finishes on 304 stainless steel. Use flood coolant to prevent heat buildup that causes surface roughening and work hardening. Higher cutting speeds with moderate feed rates typically produce superior finishes compared to slow, heavy cuts that promote work hardening.

For applications requiring better than Ra 0.4 μm, consider secondary operations like grinding, polishing, or electropolishing. Medical and food contact applications often specify Ra 0.8 μm or better for hygiene and cleaning requirements. Decorative applications may require polished finishes down to Ra 0.025 μm for mirror-like appearance.

Design Takeaway: Specify Ra 1.6 μm for standard applications. Reserve finer finishes for functional requirements like sealing surfaces or aesthetic needs, as costs increase with surface quality demands.

Conclusion

304 stainless steel offers excellent versatility for both product development and precision manufacturing applications. Its FDA compliance, adequate strength, and superior machinability make it ideal for most CNC projects requiring corrosion resistance without premium costs. Contact us to explore manufacturing solutions tailored to your 304 stainless steel product requirements.

Its role in sustainable practices and innovative technologies will only grow, keeping it at the forefront of various industries. For those requiring custom part manufacturing utilizing the robust qualities of Stainless Steel 304, reaching out to okdor at sales@okdor.com can provide the specialized assistance needed to capitalize on this versatile material.

Frequently Asked Questions

Choose 316 for marine environments, chemical exposure, or high-chloride conditions. For indoor applications and general corrosion resistance, 304 provides better value.

Specify Ra 0.8 μm or better for food contact surfaces to meet hygiene requirements. This finish is easily achievable through standard CNC machining with finish passes.

Yes, 304 stainless steel is biocompatible and commonly used for non-implantable medical devices. For implantable devices, 316L is typically preferred due to enhanced corrosion resistance in body fluids.

304 requires sharp carbide tools and proper coolant but no specialized equipment. Standard CNC machines can achieve excellent results with optimized cutting parameters.

Standard tolerance is ±0.005 mm for most features. Precision applications can achieve ±0.002 mm with proper setup and tooling. ISO 2768-m applies for general dimensions unless tighter specifications are required.

304 stainless steel costs 2-3x more than aluminum in material cost but offers superior corrosion resistance and strength. Choose based on environmental requirements and service life expectations.