Choosing the right stainless steel grade for your CNC project isn’t just about corrosion resistance—it’s about balancing performance, cost, and manufacturability without derailing your timeline or budget. After machining thousands of stainless steel parts across aerospace, medical, and industrial applications, we’ve seen how the wrong grade selection can double part costs or create unexpected production delays.

For most CNC projects, 304 stainless offers the best balance of machinability, cost, and corrosion resistance. Upgrade to 316L only when you need superior corrosion performance or are working in marine/chemical environments. Choose 17-4 PH when your design requires high strength and you can accept higher machining costs.

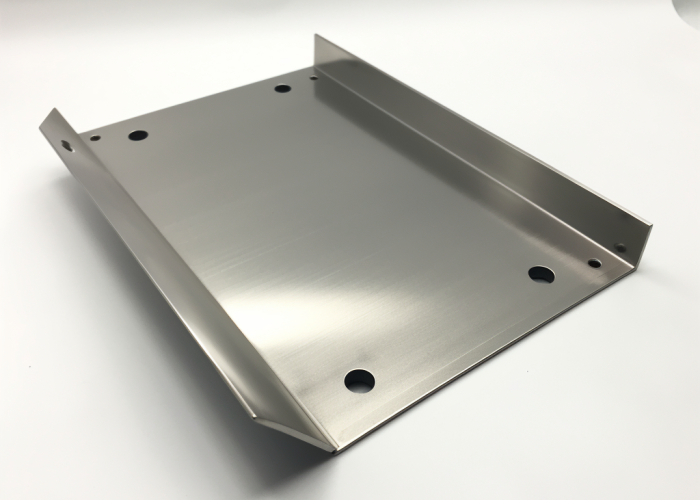

Material grade guide: cost impacts, machining challenges by design feature, and when premium grades justify costs with real tolerance and finish data.

Table of Contents

304 vs 316L vs 17-4 PH: Which Stainless Steel Should I Choose?

Choose 304 stainless for most CNC projects—it offers excellent machinability and moderate corrosion resistance at the lowest cost. Upgrade to 316L only for marine or chemical environments. Select 17-4 PH when you need high strength and can accept significantly higher machining costs.

Quick Decision Tool:

- Dry/indoor environment? → 304 stainless

- Saltwater, chemicals, or food contact? → 316L stainless

- High stress loads or springs? → 17-4 PH stainless

Grade Best For Cost vs 304 Machining Strength

304 Indoor enclosures, general brackets, medical housings (dry) Baseline Fastest, cleanest cuts Standard

316L Marine hardware, pool equipment, food processing +25-35% Slower (work hardens) Standard

17-4 PH Aircraft brackets, valve bodies, springs +50-100% Requires carbide tooling High strength

After machining thousands of stainless parts for aerospace, medical, and industrial clients, 304 handles about 70% of projects successfully. It machines cleanly and holds tight tolerances consistently. 316L becomes essential when parts face harsh environments—we’ve seen 304 components fail within months in saltwater while 316L parts remain intact after years.

17-4 PH serves applications where 304’s strength isn’t sufficient, but requires secondary heat treatment operations that significantly increase costs.

Real-world validation: We helped a medical device client switch from unnecessarily specified 316L to 304 for indoor housings—significant cost savings with zero performance issues. Conversely, a marine customer experienced 304 corrosion failure in saltwater—316L solved it permanently.

Design Takeaway: Start with 304 for most applications. Upgrade to 316L only when your environment demands superior corrosion resistance. Choose 17-4 PH when strength calculations require it.

Will This Stainless Steel Grade Hold Up in My Environment?

304 stainless works for most indoor, dry environments but fails quickly in saltwater or chemical exposure. 316L handles marine, pool, and food processing environments reliably. 17-4 PH offers similar corrosion resistance to 304 but excels in high-stress applications. Match your grade to your specific environment—not worst-case scenarios.

Environmental Decision Matrix:

- Humidity <50%, no chemicals, indoor use? → 304 sufficient

- Saltwater exposure, pool chemicals, or food contact? → 316L required

- High stress loads (>100 ksi) in dry environments? → 17-4 PH

After testing hundreds of stainless samples in various environments per ASTM B117 salt spray standards, we’ve measured clear performance differences. 304 shows visible pitting after 200-300 hours of salt exposure, while 316L remains intact beyond 1000 hours. This translates to 304 failing within 6-18 months in marine environments versus 316L lasting years.

For specialized applications beyond these common grades:

Specialty Grade Corrosion Rating Best Application Environmental Limit

410 Moderate Dry wear applications No chloride exposure

420 Limited Hardened cutting tools Indoor dry only

15-5 PH Good Aerospace structures <70% humidity

Specific environmental thresholds from our field data: Specify 316L when humidity exceeds 60% regularly, any chloride cleaning chemicals are used, or parts see temperature cycling with moisture present. Parts exposed to chloride concentrations above 25 ppm require 316L minimum per industry corrosion studies.

Real validation: We replaced failed 304 components in pool equipment after measured chloride-induced pitting compromised seal integrity. The 316L replacements passed 2-year field testing with no corrosion per visual inspection and surface profilometer measurement.

Design Takeaway: Use measurable criteria—not assumptions—for material selection. When environmental conditions meet or exceed these thresholds, specify 316L to avoid field failures that cost more than the initial material upgrade.

What Are the Machining Problems with Different Stainless Grades?

304 machines with standard HSS tooling and maintain consistent tolerances. 316L workhardens rapidly, requiring carbide tools and controlled feeds to prevent surface hardening that affects dimensional accuracy. 17-4 PH demands carbide tooling but machines predictably without work hardening issues.

Measured machining performance from our production data:

Grade Tool Life vs 304 Surface Finish (Ra) Tolerance Capability

304 Baseline 1.6–3.2 μm ±0.01 mm standard

316L 60–70% reduction 1.6–6.3 μm * ±0.01 mm (thick walls only)

17-4 PH 40–50% reduction 0.8–1.6 μm ±0.005 mm achievable

*Surface finish degrades with work hardening

Critical design thresholds that cause machining problems: Wall thickness below 2mm in 316L creates work hardening that leads to tolerance drift beyond ±0.02 mm. Our CMM measurements show 316L parts under 1.5mm wall thickness consistently exceed tolerance bands due to deflection and work hardening effects.

Measurable cost drivers: 316L requires 20-30% slower feed rates to prevent work hardening, measured through spindle load monitoring. 17-4 PH demands carbide tooling (3x tool cost) but maintains consistent cycle times. Deep pocket features with length-to-diameter ratios exceeding 4:1 double machining time due to vibration control requirements.

Manufacturing validation: We’ve measured ±0.008 mm tolerance drift in work-hardened 316L thin walls versus ±0.003 mm in properly machined thick sections using coordinate measuring machine verification per ISO 2768-m standards.

Design Takeaway: Maintain minimum 2.5mm wall thickness for 316L to avoid work hardening issues. Design features with L/D ratios under 3:1 for predictable machining costs and quality outcomes.

Which Design Features Slow Down Stainless Steel Machining?

Thin walls under 2.5mm, deep narrow pockets with length-to-diameter ratios above 3:1, and sharp internal corners significantly increase CNC cycle times and costs. Complex internal geometries requiring multiple setups create the biggest delays. Design with generous wall thickness, accessible features, and consolidated geometry to keep projects on schedule.

Quick design audit checklist: Review CAD models for these cost drivers: walls under 2.5mm, pockets deeper than 3x their width, internal corners without 0.5mm minimum radius, or features requiring tool access from multiple directions. Designs with multiple problematic features typically receive substantially higher quotes than optimized geometry.

Across aerospace, medical, and industrial projects, we consistently see specific features create production bottlenecks. Thin-wall features often fail dimensional requirements due to machining-induced deflection, while deep pockets requiring specialized long-reach tooling increase cycle times and tool breakage risk.

Sharp internal corners cannot be machined because cutting tools are round—minimum 0.5mm radius enables faster cutting speeds and more robust tooling. When functional requirements prevent design changes, consider temporary machining ribs, split assemblies, or secondary joining operations.

Real optimization impact: Electronics manufacturer’s bracket with thin walls and sharp corners required redesign. Modifications to 3mm wall thickness and 0.5mm corner radii achieved major cost reductions without compromising structural performance.

Design Takeaway: Specify minimum 2.5mm walls, 0.5mm+ internal radii, and pocket depths under 3x width. Well-optimized designs typically receive significantly more competitive quotes while maintaining equivalent performance.

Why Do 316L CNC Quotes Cost More Than 304?

316L material costs more than 304, but total project costs increase substantially due to machining complexity, extended lead times, and supply chain factors. Work hardening behavior and accelerated tool wear create compound cost penalties that multiply at higher production volumes.

Budget planning by volume: At prototype quantities (1-10 pieces), expect moderate premiums. At production volumes above 100 pieces, cost differences become substantial due to material, machining, and procurement factors compounding over larger quantities.

Supply chain considerations impact project timelines significantly. 316L bar stock typically requires longer procurement than readily available 304, particularly for non-standard sizes. This often forces expedited shipping that adds costs when schedules are compressed.

Manufacturing complexity drives the largest cost penalties. 316L’s work hardening characteristics force conservative machining parameters to prevent surface hardening that compromises dimensional accuracy. Tool life decreases notably, requiring more frequent replacements throughout production runs.

Cost-benefit validation: Medical device manufacturer initially specified 316L for indoor electronic housings based on conservative material selection. Environmental assessment revealed no chloride exposure or aggressive cleaning requirements. Material substitution to 304 achieved significant project savings while meeting all performance requirements.

Alternative strategies: Consider environmental controls, protective coatings on 304, or design modifications eliminating corrosive exposure before accepting 316L premiums.

Design Takeaway: Specify 316L only when measurable environmental conditions demand enhanced corrosion resistance. Avoid conservative specifications that add substantial cost without functional benefit.

Are My Stainless Steel Tolerances Too Tight for CNC?

Most CNC stainless steel parts achieve ±0.05mm tolerances reliably. Tighter tolerances like ±0.01mm are possible but require specialized fixturing and increase costs significantly. 316L’s work hardening makes tight tolerances more challenging than 304. Reserve precise tolerances for critical features only.

How to specify tolerances on your drawings: Use general tolerance notes like “±0.05mm unless otherwise specified” for non-critical dimensions, then call out specific tolerances only where needed. ISO 2768-m provides standard general tolerance classes that most CNC shops understand without additional explanation. For mating surfaces and assembly-critical features, specify tighter tolerances directly on those dimensions.

Validating your supplier’s capability during quoting: Ask these specific questions: “What’s your standard tolerance capability for 316L parts?” and “Do you have CMM inspection capability for verification?” Request sample tolerance studies or capability data for parts similar to yours. Red flag: suppliers who claim ±0.005mm capability on all features without considering part geometry or material constraints.

Based on our CMM validation following ISO standards, wall thickness directly affects tolerance achievement. Features under 2mm struggle with tight tolerances due to deflection, regardless of material grade. When quoting, specify which tolerances are critical for function versus those that can be relaxed if manufacturing challenges arise.

Tolerance specification strategy: Start with ±0.05mm general tolerances and apply ASME Y14.5 geometric dimensioning principles. Tighten only functionally critical dimensions like bearing fits, mating surfaces, or assembly interfaces. Many “tight” tolerances provide no functional benefit and exist from conservative design habits.

Verification requirements: Require first-article inspection reports showing actual measured dimensions versus specifications. Request measurement uncertainty data to ensure your supplier’s equipment can reliably measure your tolerance requirements.

Design Takeaway: Default to ±0.05mm general tolerances, specify tighter tolerances only where functionally required, and validate supplier capability before finalizing specifications.

What Secondary Operations Will My Stainless Parts Need?

Most CNC stainless parts require deburring and surface finishing as standard operations. Heat treatment applies to precipitation-hardening grades like 17-4 PH. Passivation enhances corrosion resistance, while electropolishing provides smooth, cleanable surfaces for medical and food applications.

Vendor coordination and capability assessment: Most CNC shops partner with local finishing vendors but don’t perform all operations in-house. Ask upfront: “Which secondary operations do you handle internally versus subcontract?” This determines your vendor management complexity and affects project coordination requirements.

Operation-specific specification requirements:

- Passivation: Specify ASTM A967 standard and nitric acid test acceptance criteria

- Electropolishing: Define required surface finish (Ra values) and specify treatment areas

- Heat treatment for 17-4 PH: Specify target hardness range and required certification

- Surface finishing: Provide clear drawings showing which surfaces need special treatment

Vendor management for multi-operation parts: For complex parts needing multiple secondary operations, designate one primary vendor to coordinate the entire process. This reduces your project management burden and creates single-point accountability for quality and delivery schedules.

Certification and documentation requirements: Establish acceptance criteria before production begins to avoid disputes over subjective appearance standards. Require specific certifications: hardness testing results for heat treatment, nitric acid test compliance for passivation, surface finish measurements for electropolishing.

Cost optimization strategies: Basic deburring adds minimal expense. Electropolishing significantly increases part cost. Specify secondary operations only where functionally required—over-specification adds expense without performance benefit.

Design Takeaway: Plan secondary operations during initial design phase, establish clear vendor responsibilities, and define acceptance criteria upfront to ensure quality and delivery success.

Conclusion

Choosing the right stainless steel grade balances performance requirements with manufacturing realities. 304 serves most applications cost-effectively, while 316L justifies its premium in corrosive environments. Smart tolerance specification and early secondary operation planning prevent budget surprises and schedule delays.

Contact us to explore manufacturing solutions tailored to your stainless steel machining requirements.

Frequently Asked Questions

316L can achieve similar surface finishes to 304, but work hardening makes it more challenging. Standard Ra 1.6-3.2 μm finishes are achievable on both grades. For finer finishes or complex geometry, 316L may require electropolishing or additional finishing operations that 304 doesn’t need.

No, anodizing only works on aluminum and its alloys. Stainless steel uses different finishing processes: passivation for enhanced corrosion resistance, electropolishing for smooth bright surfaces, or mechanical finishing like bead blasting for uniform appearance. Each provides different aesthetic and functional benefits.

304 stainless typically ships within days from local suppliers and machines fastest. 316L requires longer procurement (1-2 weeks typical) and machines slower due to work hardening characteristics. Precipitation-hardening grades like 17-4 PH add heat treatment time (1-2 weeks) after machining, extending total delivery schedules.

Evaluate actual operating conditions: Will parts see saltwater, pool chemicals, or cleaning agents stronger than soap? Does humidity regularly exceed 60%? Are chlorides present in the environment? If yes to any of these, 316L provides necessary corrosion resistance. When uncertain, test 304 samples in actual conditions or choose 316L for peace of mind.

Material certifications depend on your industry and application requirements. Medical device manufacturers typically need mill test certificates for traceability. Aerospace applications often require full material certifications per AS9100 standards. For general industrial use, certifications are usually optional but available upon request for nominal cost.

For most CNC machined stainless parts, ±0.05mm is achievable with standard tooling and processes. Going tighter than ±0.01mm often requires specialized fixturing or climate-controlled environments, which increases cost significantly. We recommend tolerancing only critical features tightly and keeping others at ISO 2768-m levels for cost efficiency.