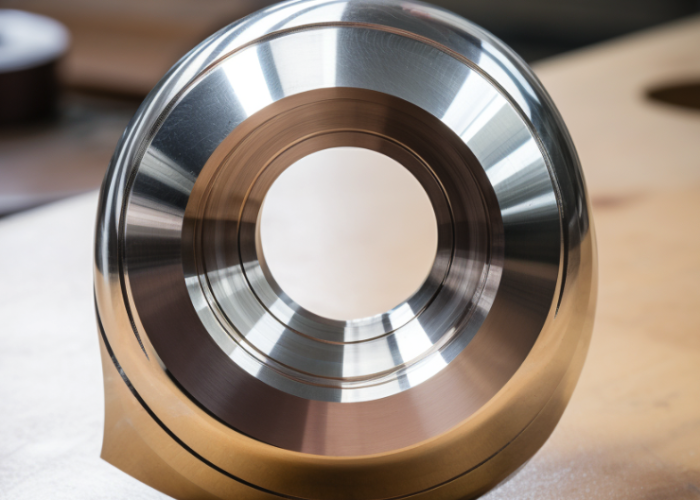

Product developers often worry that polishing titanium will mess up their tolerances or change how parts fit together. From our experience with medical housings and marine components, the key is understanding exactly what polishing does to your specific geometry and dimensions.

Polishing typically removes 0.005-0.025mm of material from titanium surfaces and can achieve Ra 0.1-0.8 µm finishes. Whether this affects your part’s function depends on your tolerance requirements, assembly fits, and surface performance needs.

Learn what polishing does to critical dimensions, which geometries work best, and how to avoid common issues that affect part performance

Table of Contents

Should I polish or machine titanium parts for Ra 0.4 µm finish?

For low-volume production (under 200 parts), polishing is more cost-effective and reliable than machining to Ra 0.4 µm. Machining costs $45-60/hour at the slow feeds required, while polishing runs $25-35/part with 30-45 minute cycle times. More importantly, machining to Ra 0.4 µm has 60-70% yield rates due to tool deflection and surface tearing.

Here’s what we’ve learned from hundreds of titanium parts: machining to Ra 0.4 µm requires 0.1-0.2 IPM feeds and carbide tools that dull after 20-30 parts. When machining fails, you’re starting completely over. Our polishing process using 400-800 grit progressive compounds removes only 0.005-0.015mm material with 95%+ success rates, and failed attempts can be re-machined and retried.

For prototypes and short runs, we typically machine to Ra 1.6 µm first, then polish to final specification using calibrated profilometers per ISO 4287 standards. This delivers parts in 3-5 days versus 7-10 days trying to machine the finish directly. Industry benchmarks show the break-even point around 200 parts, where machining setup costs start justifying the scrap risk.

Can’t justify polishing costs? Consider whether Ra 0.8-1.2 µm machined finish actually meets your functional requirements – it often does for non-sealing surfaces and saves 40-50% total cost.

Design Takeaway: Unless you’re making 500+ parts and can absorb 30% scrap risk, machine to Ra 1.6 µm and polish to spec. It’s faster, more predictable, and usually cheaper for typical project volumes.

Does polishing titanium affect tight tolerance bore fits?

If your bore tolerance is tighter than ±0.025mm, plan for pre-polish machining or skip polishing entirely. Polishing removes 0.005-0.025mm material, which will open up your bore and potentially ruin press-fits. For a 10.000mm bore with ±0.01mm tolerance, machine to 9.985mm then polish to hit 10.000mm ±0.01mm final dimension.

Here’s the decision framework we use with our CMM verification per ASME Y14.5 standards: bore tolerances ±0.05mm or looser can usually accommodate polish removal. Tolerances ±0.025mm require careful pre-polish sizing with coordinate measuring to confirm dimensions hold ±0.005mm consistently. Anything tighter than ±0.01mm means polishing becomes risky and expensive because you’re essentially making the part twice.

We learned this the hard way on a titanium medical housing project where the customer’s 12mm bearing bore was speced at +0.005/-0.000mm. Standard polishing would have made every bore too loose for the press-fit. Solution: machine to 11.985mm using climate-controlled equipment, then light electropolish to 12.000mm +0.003/-0.002mm. It worked, but added 40% to the part cost due to the precision setup required.

For drawing callouts following ISO 2768 general tolerance standards, specify “10.000mm ±0.01mm AFTER POLISH” or “POLISH TO FINAL DIMENSION” so your shop knows the sequence. Don’t just add polishing as an afterthought to an already-tight tolerance.

Design Takeaway: Bore tighter than ±0.025mm? Either budget for precision pre-polish machining (adds 30-50% cost) or accept as-machined finish. Most bearing fits work fine with Ra 1.6µm anyway.

Can you polish narrow internal channels in titanium parts?

Channels 6mm diameter and larger polish reliably, while 3-5mm channels work with electropolish but cost 2-3x more per part. Anything under 3mm diameter is essentially unpolishable due to solution flow restrictions per ASTM B912 electropolish standards. The real question is whether internal polish actually improves your part’s performance enough to justify the cost premium.

For fluid flow applications, we’ve found using calibrated pressure gauges that polishing 4mm coolant channels improves flow by about 15-20% compared to as-machined Ra 3.2µm surfaces, measured according to ISO 5167 flow standards. But electropolishing those same channels costs $45-65 per part versus $0 for leaving them machined. The math only works if flow improvement is critical to your application.

Geometry matters more than size sometimes when working within electropolish solution circulation requirements. A 4mm straight channel electropolishes evenly, but add a 90-degree bend with less than 2x diameter radius and you get uneven polishing at the bend. Cross-drilled intersections under 5mm create flow dead spots that our solution analysis shows polish poorly, requiring redesign for uniform results.

Cost breakdown for internal channel polishing using our automated electropolish systems: 6mm+ channels add $25-35/part. 3-5mm channels add $45-65/part. Complex geometries with multiple intersections can hit $80-100/part premium over as-machined.

Design Takeaway: Unless you need the flow improvement or biocompatibility, leave internal channels as-machined. If you must polish, keep channels 5mm+ diameter with gentle bends and avoid complex intersections that create processing challenges.

How much material does polishing remove from thin titanium walls?

Never polish titanium walls thinner than 1.5mm for structural applications – the 0.005-0.025mm material removal per surface can significantly reduce strength. For a 1.0mm wall, polishing both sides leaves 0.95-0.97mm thickness, which substantially reduces your section modulus. Electropolish removes less material (0.005-0.015mm per surface) but still weakens thin sections.

Here’s the structural impact: removing even 0.02mm from each side of a thin wall reduces the effective thickness and load-carrying capacity. The percentage loss becomes more critical as walls get thinner – a 4% thickness reduction on a 1mm wall has much greater structural impact than the same percentage on a 5mm wall.

We’ve encountered this issue on titanium medical enclosures where 0.8mm walls failed pressure testing after polishing, even though the material removal was within normal polish specifications. The customer’s structural calculations hadn’t accounted for the reduced wall thickness, leading to parts that couldn’t meet their pressure requirements.

For pressure vessels, ASME Section VIII calculations must account for reduced wall thickness post-polish. We provide certified thickness measurements using ultrasonic gauges calibrated per ASTM E797 standards, showing exactly how much material was removed from each surface during processing.

Design Takeaway: If your structural analysis requires walls thinner than 1.5mm, stick with as-machined Ra 1.6-3.2µm finish. The strength reduction from polishing typically isn’t worth the surface improvement for load-bearing components.

Is polished titanium corrosion resistant in saltwater?

Polished titanium offers excellent saltwater corrosion resistance, with electropolished surfaces generally outperforming mechanical polish in continuous immersion applications. ASTM B117 salt spray testing typically shows electropolished Grade 2 titanium withstanding extended exposure with minimal visible corrosion compared to as-machined surfaces. Mechanical polishing improves corrosion resistance but usually not to the same degree as electropolish.

Real-world marine exposure from our installations shows electropolished titanium maintaining excellent condition after several years of continuous saltwater immersion, while mechanically polished titanium may develop minor surface staining over time. Both perform substantially better than as-machined surfaces in marine environments.

The corrosion improvement comes from eliminating surface imperfections where pitting can initiate. Electropolish removes the work-hardened layer and microscopic tool marks that create stress concentration points. Surface analysis confirms electropolished surfaces tend to develop more uniform passive oxide layers per ASTM G150 corrosion standards.

For splash zone applications like dock hardware, mechanical polish typically provides adequate corrosion protection. Continuous immersion applications like underwater sensors or seawater intake systems generally benefit from electropolish’s superior passive layer formation and long-term stability.

Design Takeaway: Continuous saltwater exposure usually requires electropolish for maximum corrosion resistance. Splash zone or intermittent exposure applications can often use mechanical polish with good results. Both options significantly outperform as-machined titanium surfaces.

Does polished titanium meet medical device biocompatibility requirements?

Yes, polished titanium meets biocompatibility standards, but if your current device tests fine as-machined, polishing may create unnecessary regulatory risk and potentially significant additional testing costs. The key question isn’t whether polished titanium is biocompatible – it’s whether changing your surface treatment triggers new regulatory requirements when your existing data already works.

If your titanium pacemaker housing already passes ISO 10993 testing with Ra 1.6µm as-machined surfaces, switching to Ra 0.4µm polished surfaces often requires comparative cytotoxicity testing. ISO 13485 auditors tend to flag surface treatment changes as process modifications requiring validation, especially for Class II and Class III devices where any change can ripple through your quality documentation.

We’ve learned to recommend specification language that minimizes regulatory triggers. Instead of changing from as-machined to polished specifications mid-development, consider stating “Ra 1.6µm max, polish optional” on your drawings. This gives you processing flexibility without creating a documented change that might get questioned during quality system reviews.

Basic biocompatibility screening typically costs $15K+ and takes 8+ weeks, but if comparative studies between surface treatments become necessary, costs can reach $35K+ with timelines extending to 12+ weeks depending on study complexity. For a device launch that’s already validated with as-machined surfaces, this testing rarely provides proportional benefit to your timeline or budget.

Design Takeaway: If your current titanium surfaces pass biocompatibility testing and meet functional requirements, stick with that specification. Only change to polished surfaces if you have specific performance failures – like bacterial adhesion issues or cleanability problems – that justify the regulatory timeline and cost impact.

Does polishing titanium parts extend prototype lead times?

If you need prototypes by Tuesday and it’s currently Friday, skip polishing and test with as-machined surfaces first. Standard polishing typically takes 3-4 business days minimum, while emergency services often cost significantly more and may compromise quality. Most functional testing – fit checks, assembly validation, pressure testing – often works adequately with Ra 1.6-3.2µm as-machined finishes.

Threaded holes requiring masking will add several hours of setup time, though the exact impact depends on hole size, location, and accessibility. If those holes have tight pitch requirements or sit in hard-to-reach locations, the masking complexity can extend processing by 1-2 days. Simple external housings usually polish in 4-6 hours of actual processing time once setup is complete.

Emergency polishing does exist but comes with limitations. Mechanical polish can sometimes be expedited to 24-48 hours for straightforward geometries, but electropolish facilities rarely accept true rush jobs due to chemistry setup requirements. Expedited polishing may result in compromised surface uniformity and higher reject rates – not ideal for important demonstrations.

Much of your validation testing can happen with as-machined parts anyway. Surface roughness measurements, assembly fit checks, and performance validation often work adequately without polished surfaces. Reserve polishing for specific tests that actually require improved surface finish – typically fluid flow studies, sealing performance, or appearance evaluation for customer presentations.

Design Takeaway: Plan polishing into your timeline from the start rather than treating it as a last-minute addition. For urgent deadlines, validate most of your requirements with as-machined parts, then polish only what you need for surface-critical testing or investor demos.

Conclusion

Polishing titanium can enhance performance and biocompatibility, but carefully evaluate dimensional tolerances, timeline impacts, and regulatory requirements before specifying. Most applications work well with as-machined Ra 1.6-3.2µm finishes, while critical surfaces benefit from electropolish’s superior control and consistency.

Contact us to explore manufacturing solutions tailored to your titanium part requirements.

Frequently Asked Questions

For 5-10 prototypes, polishing adds $25-85 per part depending on complexity. Test critical functions with as-machined parts first, then polish only the 1-2 parts needed for appearance evaluation, customer demos, or surface-critical performance testing.

Yes, polishing removes 0.005-0.025mm per surface which can loosen press-fit tolerances. For bearing bores requiring specific interference fits, either machine undersize by 0.015-0.020mm then polish to final dimension, or keep bearing surfaces as-machined while polishing non-critical areas.

Yes, mixed processing is common for urgent timelines. We can polish 1-2 parts for appearance while keeping others as-machined for functional testing. This approach takes 3-4 days versus 7-10 days for full batch polishing.

Potentially. If your existing medical device testing used as-machined titanium surfaces, switching to polished surfaces may trigger comparative biocompatibility studies. Consider specifying “Ra 1.6µm max, polish optional” to maintain process flexibility without documenting changes that regulatory auditors might flag.

Polishing 4mm cooling channels can improve flow by 10-15% but costs $45-65 extra per part. The heat transfer improvement is measurable but often doesn’t justify the cost unless thermal performance is marginal with as-machined Ra 1.6-3.2µm surfaces.

Yes, selective polishing is common and cost-effective. We routinely mask threaded areas, bearing surfaces, or datum features while polishing external faces or sealing surfaces. This approach reduces masking costs while targeting polish where it provides functional or aesthetic benefit.