Does Vibration Really Help in Cutting?

Yes, it does. Vibration cutting isn’t just a buzzword; it’s a game-changer in the machining world. Enter vibration cutting. This isn’t just a trend—it’s a revolution in machine tools. By introducing controlled vibrations, we’re enhancing the cutting tool‘s efficiency and redefining precision in the machining process.

Table of Contents

This guide covers everything from the intricate science behind vibration-assisted machining to its practical implications on workpiece material and tool life. Whether battling tool chatter or looking to optimize spindle speeds, we’ve got insights to elevate your machining operations.

Diving Deeper into Vibration Cutting

Vibration cutting is more than just a buzzword; it combines machine tool structure, cutting forces, and tool holder dynamics. We can fine-tune the cutting-edge’s performance by harnessing these elements, ensuring smoother spindle speeds, and minimizing chatter in machining.

Boosting the Cutting Process

Vibration doesn’t just add a rhythmic dance to your machine tools—it amplifies the entire operation. From streamlining chip formation to achieving perfect surface quality, vibration cutting sets new standards in high-speed machining and CNC turning.

Vibration Cutting vs. Traditional Cutting: A Side-by-Side Look

Efficiency: Racing Against the Clock

CNC machines and manufacturing processes operate rapidly, so every second counts. Traditional cutting, while reliable, often feels like driving with the handbrake on.

Vibration cutting, on the other hand, is like hitting the turbo button. By leveraging controlled vibrations, we can significantly speed up the machining process, making quick work of even the toughest workpiece materials. It’s not just about cutting faster—it’s about cutting smarter.

Precision: Nailing the Bullseye

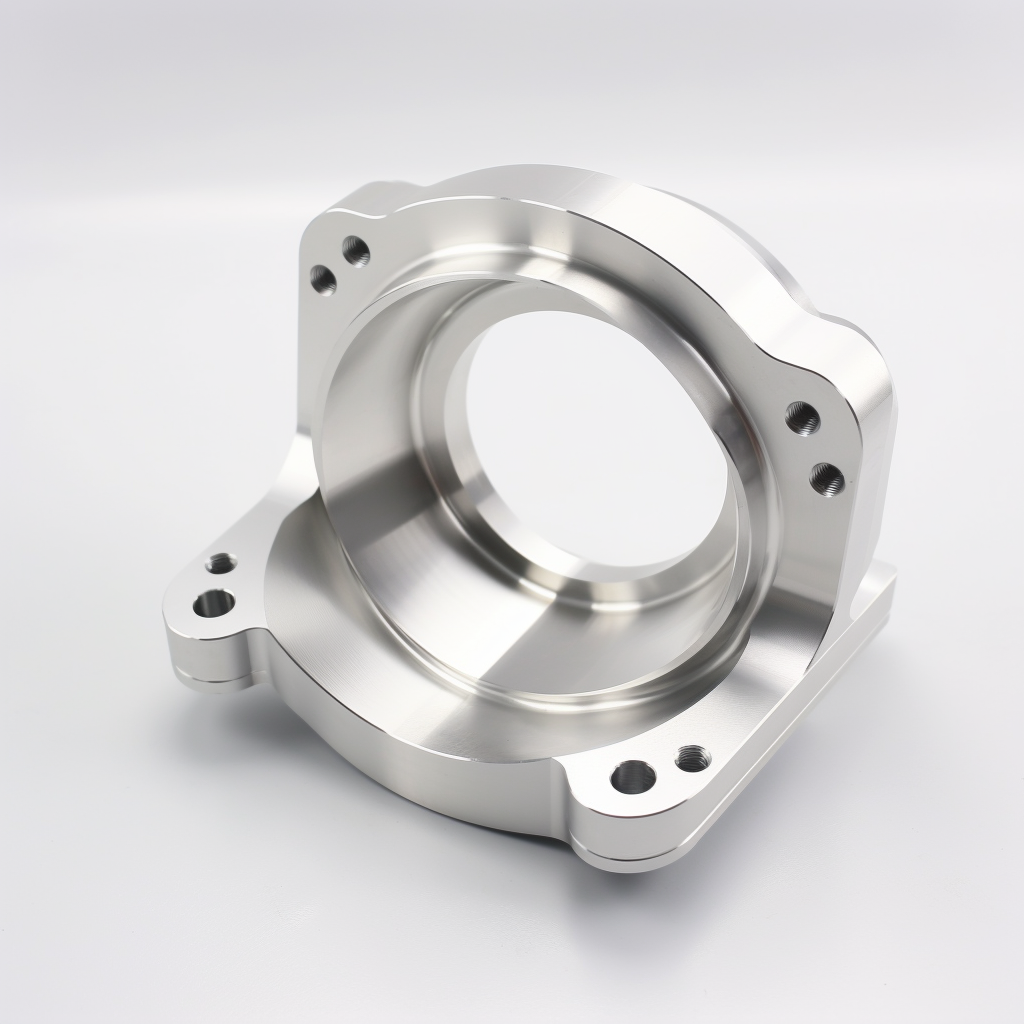

Remember those pesky chatter marks that traditional methods sometimes leave behind? With vibration cutting, those are largely a thing of the past. The precision of this method is unparalleled.

The machined surface quality achieved is often smoother, and the dimensional accuracy is spot-on. While conventional milling has merits, vibration cutting often takes the crown when delivering that perfect finish.

Tool Life: The Longevity Game

Every machinist knows the pain of frequent tool replacements. Traditional cutting, especially in challenging machining operations, can be hard on your tools.

Enter vibration cutting—a method that not only reduces tool deflection but also ensures even chip load distribution. The result? Your cutting tools and tool holders face less wear and tear, promising a longer tool life. It’s like giving your tools a new lease on life.

Specific Scenarios: Where Each Method Shines

While vibration cutting is a game-changer, it’s not the answer to everything. For instance, traditional methods still hold the edge in scenarios requiring rigid tool paths or when working with certain materials.

However, vibration cutting is the way to go when you want to reduce chatter in high-speed machining or aiming for that perfect machined surface. It’s all about picking the right tool for the job.

Material-Specific Advantages of Vibration Cutting

Metals: From Soft Aluminum to Rugged Titanium

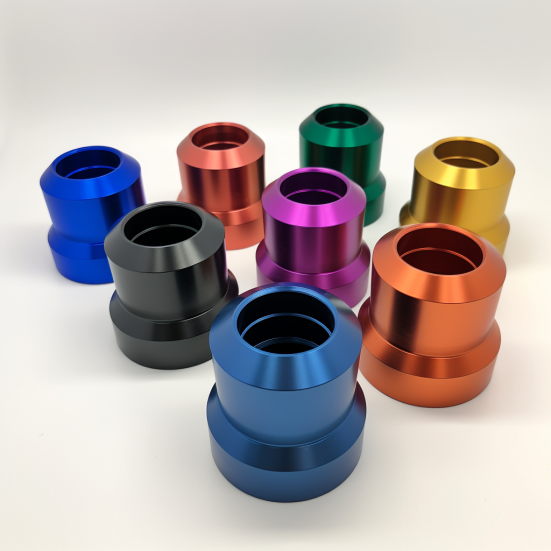

The machine tool equipped with vibration-cutting technology is a game-changer in metals. When subjected to the cutting process, soft metals like aluminum often face challenges like tool chatter and unwanted vibration. However, the cutting forces are evenly distributed with vibration cutting, ensuring a smoother chip formation process.

Hard metals like titanium, notorious in the machining world for their resistance, benefit from reduced cutting forces and an improved machined surface. Whether it’s the malleability of aluminum or the resilience of titanium, vibration cutting, with its precise tool path, offers a tailored approach for each metal.

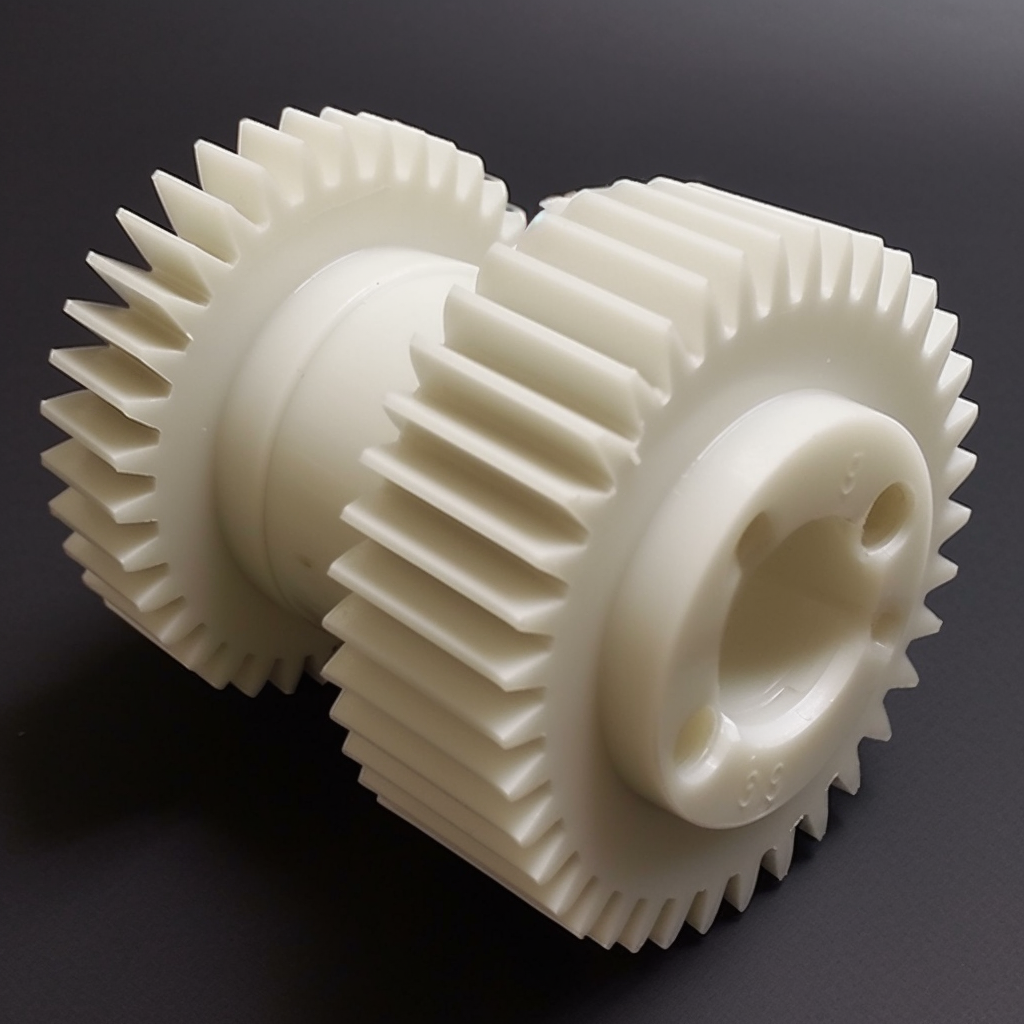

Non-metals: Beyond the Realm of Metals

Beyond metals, the cutting tool with vibration-cutting technology showcases its versatility. Plastics, often sensitive to heat and prone to melting during conventional milling, experience reduced thermal effects and minimized chatter. Ceramics, known for their brittleness, see fewer instances of cracking thanks to the controlled cutting force and vibration characteristics.

Composites, with their layered structure, benefit from a uniform finish, reducing the chances of delamination. The machine tools equipped with vibration-cutting technology aren’t just for metals—they’re a universal solution.

Hard vs. Soft: A Tale of Two Extremes

The beauty of vibration cutting lies in its adaptability. When subjected to machining, soft materials often face challenges like forced and self-excited vibrations.

However, these challenges are addressed with vibration cutting, ensuring minimal chatter and a smoother machining process.

On the other hand, hard materials benefit from reduced tool wear and improved workpiece quality, thanks to the even distribution of cutting forces and the machine tool’s vibrations being kept in check.

Material Challenges: Navigating the Maze

Every material comes with its own set of challenges in the machining world. Some might be prone to heat deformation, while others might be sensitive to mechanical vibrations. Vibration cutting addresses these unique considerations with its controlled approach and precise tool path.

For instance, materials with complex structures might face challenges like regenerative chatter during the metal cutting. However, vibration cutting minimizes these challenges, ensuring every cut is a step towards perfection.

The Mechanics of Vibration Cutting

Equipment and Tools: The Heart of Vibration-Assisted Machining

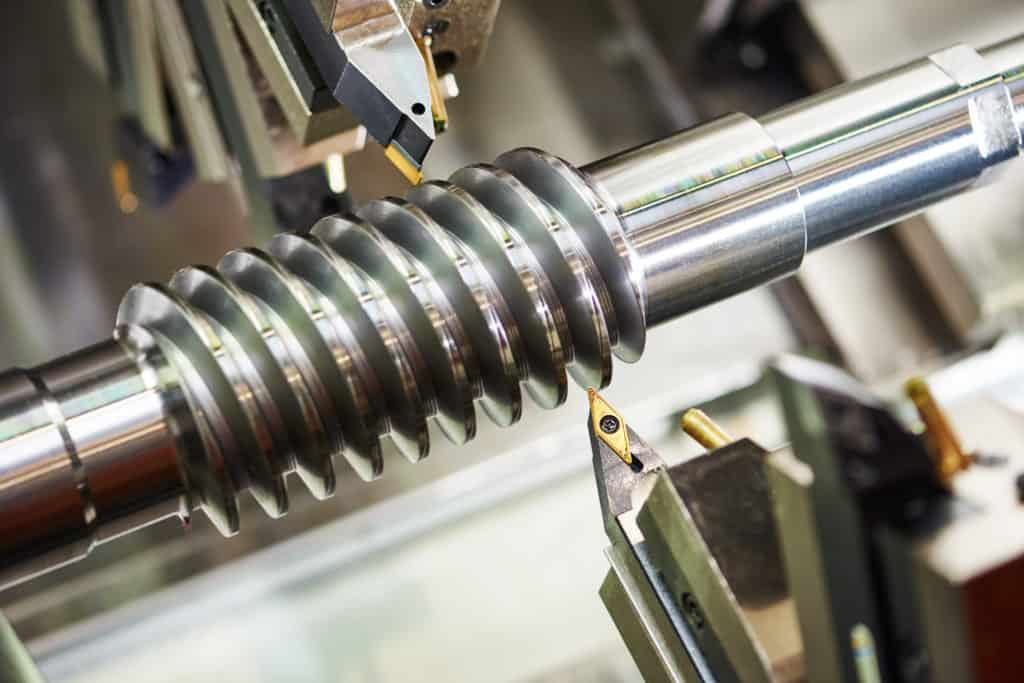

Regarding vibration cutting, the machine tool is the star of the show. With precision-designed cutting tools, these machine tools are the backbone of vibration-assisted machining.

The tool holder ensures stability, while the cutting edge, sharpened to perfection, interacts with the workpiece. But it’s not just about the tools. The cnc machine, with its advanced capabilities, plays a pivotal role in controlling the chatter vibration and minimizing chatter marks, ensuring a seamless machining process.

Diving Deep: Frequency, Amplitude, and More

Understanding vibration cutting goes beyond just the equipment. It’s about diving deep into the technical aspects. The frequency response function gives insights into how the machine tool vibrations interact with the cutting force. The spindle speed, synchronized with the same frequency of the machine chatter, ensures optimal cutting.

Natural frequencies, resonant frequencies, and damping coefficients are crucial in reducing chatter and preventing tool breakage. The stability lobe diagram visually represents the machining system’s behavior, ensuring the tool doesn’t vibrate freely and maintains a consistent chip thickness.

Benefits Beyond the Cut

Longevity: More Than Just a Cut

One of the standout benefits of vibration cutting is the reduced wear and tear on cutting tools. By controlling tool chatter and minimizing forced vibrations, the cutting edge remains sharp for longer durations. This ensures a consistent cut and reduces the frequency of tool replacements, making it a cost-effective solution in the long run.

Energy Efficiency and More: The Unsung Heroes

Vibration cutting isn’t just about the cut but the entire machining system. By optimizing the cutting parameters and ensuring the machine tools operate at their peak efficiency, energy consumption is reduced. This translates to cost savings and positions vibration-assisted machining as an eco-friendly alternative.

And let’s remember the improved surface finish. With minimized chatter vibrations and a controlled chip load, the result is a workpiece free from chatter marks and with a finish that speaks volumes about the quality of the machining process.

Challenges and Considerations

otential Pitfalls of Vibration Cutting

While vibration cutting offers numerous advantages, it’s essential to be aware of potential challenges. The machine tool, while advanced, can sometimes struggle with excessive tool chatter, leading to machining vibration.

This can be exacerbated if the spindle speed needs to be optimized, leading to chatter in machining. While enhanced by vibration, self-excited vibration can sometimes hamper the metal cutting, especially if the damping coefficient isn’t well-calibrated.

When Vibration Cutting Might Not Make the Cut

Vibration cutting, like all machining processes, isn’t a one-size-fits-all solution. In situations where the machining system requires ultra-precision or when working with materials that have a high risk of producing too much material as waste, traditional methods might be preferable.

The stability lobe diagram can be a valuable tool in these scenarios, helping manufacturers determine the limiting factor and whether the cnc machine, with its current settings, is the right choice.

Conclusion

Let’s cut to the chase: vibration cutting isn’t just another buzzword in the machining world. It’s a game-changer. From the intricate dance of the machine tool and cutting tool to the symphony of minimized tool chatter, we’ve delved deep into the mechanics and benefits of this technique. We’ve seen how it can revolutionize industries, offering unparalleled precision and efficiency. But it’s not just about the here and now; it’s about the potential.

Frequently Asked Questions

Machining chatter is an unwanted form of machining vibration during cutting operations. It’s due to the cutting tool and tool holder interacting in a way that causes oscillatory motions, leading to poor surface finish and reduced tool life.

Various factors, including excessive wear on the cutting tool, improper tool holder setup, and machining vibration, can cause milling chatter. The interaction between the cutting tool and the workpiece can lead to machine chatter.

The vibration cutting method involves machining vibration to assist the cutting tool. This method can improve surface finish, reduce cutting forces, and extend tool life. It is possible to induce vibrations by ultrasonically or through other means.

– You can neutralize vibration through various methods:

– Using vibration-dampening materials or isolators.

– Balancing rotating equipment to reduce imbalance-induced vibrations.

– Adjusting the spindle speed of machinery to avoid resonant frequency.

– Implementing active vibration control systems that counteract vibrations with opposing forces.

Vibrations in metal cutting refer to the machining vibration during the process. These vibrations can arise from the cutting tool and workpiece interaction, leading to machining chatter.

– To reduce or eliminate chatter in machining:

– Optimize the machining processes to ensure regular engagement of the cutting tool.

– Use the right tool holder to ensure maximum rigidity.

– Adjust the spindle speed to avoid resonance.

– Ensure proper machine setting and maintenance to minimize chatter.

– The primary types of chatter in machining are:

– Tool Chatter occurs when the cutting tool vibrates during operations, leading to machining vibration.

– Workpiece Chatter: This happens when the workpiece isn’t fixed correctly, causing machining chatter.

Forced vibrations in machine tools arise from external sources, such as imbalances in the machinery or external disturbances. During the metal–cutting, these vibrations can lead to uneven chip thickness, reduced tool life, and poor surface finish. It’s essential for tool manufacturers, like Harvey Tool, to design tools that can withstand these vibrations and ensure consistent performance.

Regenerative chatter is a self-excited vibration that occurs due to the interaction between the cutting tool and the workpiece. As the tool cuts, it leaves behind wavy surfaces, which, when encountered in subsequent passes, can lead to vibrations. This phenomenon can amplify itself, leading to chatter. On the other hand, workpiece chatter is primarily due to the mechanical system’s dynamics, such as the flexibility of the workpiece or the machining system. Both types of chatter can be detrimental, causing unwanted vibration, tool wear, and poor finish.

Tool holders are pivotal in minimizing chatter by ensuring the cutting tool is securely and accurately positioned. A well-designed tool holder, combined with the right modal mass of the mechanical system, can dampen vibrations and reduce the chances of chatter. The modal mass represents the system’s resistance to dynamic motion, and a higher modal mass can help absorb and dissipate energy, thus reducing the occurrence of chatter in machining.