Product developers often ask us about marking options for their CNC-machined parts — whether to specify laser engraving, CNC engraving, or other methods during design. With years of experience integrating laser engraving with precision machining across aerospace, medical, and audio projects, we’ve learned that the right marking choice early in design saves both cost and lead time.

Laser engraving offers ±0.05 mm precision with minimal material impact, making it ideal for permanent marking, traceability codes, and decorative features on machined parts. Unlike CNC engraving, laser processes are non-contact, reducing setup complexity and enabling marking after final machining operations without affecting tolerances.

Discover when laser engraving is best, how it fits CNC workflows, and design tips to boost mark quality and efficiency—plus real cost and tolerance data.

Table of Contents

When Should You Use Laser Engraving vs CNC Marking?

Laser engraving is best for shallow marking (0.1-0.3 mm) with minimal setup, while CNC marking works better for deep engravings over 0.5 mm or when combining with other machining operations.

Choose Laser Engraving When:

- Your parts need identification marks, serial numbers, or logos under 0.3 mm depth

- Working with pre-finished parts where fixturing stress could cause damage

- Running high-volume batches where tool wear consistency matters

- Adding markings after heat treatment or coating processes

We recently worked with a medical device manufacturer who needed deep identification channels (0.8 mm) for tactile recognition by users wearing gloves. CNC engraving was the only viable option since laser couldn’t achieve the required depth while maintaining clean sidewalls. Meanwhile, an aerospace customer needed thousands of serial numbers on titanium brackets—laser engraving eliminated tool replacement costs and maintained consistent character quality throughout the entire production run while meeting AS9100 traceability requirements.

For most applications, laser engraving reduces setup time by eliminating tool changes and fixture modifications. However, when markings must align precisely with machined features or require depths exceeding 0.5 mm for functional purposes, CNC engraving within the same setup ensures positional accuracy.

Design Takeaway: Specify laser engraving for identification marks, logos, and decorative features under 0.3 mm depth. Use CNC engraving when marking depth exceeds 0.5 mm or when engravings must be machined during the same setup as critical features to maintain positional accuracy.

What Tolerances Can Laser Engraving Achieve?

Laser engraving achieves ±0.025 mm positional accuracy and ±0.05 mm depth control for most applications. Minimum feature sizes start at 0.1 mm line width and 0.5 mm character height, making it suitable for identification marking but not precision mechanical features.

Laser tolerance capabilities are determined by beam spot diameter and system stability. Most industrial lasers operate with 0.1-0.2 mm spots, directly affecting minimum feature resolution. Unlike mechanical processes, laser systems maintain consistent accuracy across the entire work area since there’s no tool deflection or wear to consider.

For comparison, CNC engraving typically achieves ±0.01 mm but requires tool access and setup time that laser systems avoid. The trade-off is depth capability—CNC can create deeper, more precise features while laser excels at shallow, high-volume marking applications.

Achieving tighter tolerances increases processing cost significantly. Standard laser tolerances (±0.05 mm) work well for serial numbers and logos, while precision applications requiring ±0.025 mm need slower processing speeds and multiple passes, adding 30-50% to cycle time.

Design Takeaway: Use standard laser tolerances (±0.05 mm) for identification and decorative features. Reserve tighter specifications (±0.025 mm) only for functional alignment marks where the added cost is justified by assembly requirements.

Does Laser Engraving Work on All CNC Materials?

Laser engraving works on aluminum, stainless steel, and most engineering plastics, but not on highly reflective materials like polished copper or chrome-plated surfaces.

Material Type Compatibility Marking Quality

6061-T6 Aluminum Excellent Clean edges, good contrast

7075-T6 Aluminum Excellent No property degradation

304/316 Stainless Excellent High contrast marking

Brass/Bronze Good Requires power optimization

POM/Delrin Good Some discoloration possible

PEEK/Nylon Fair Limited contrast available

Polished Copper Poor High reflectivity issues

Chrome Plating Not Recommended Coating delamination risk

We’ve processed aerospace components in 7075-T6 with laser-engraved identification codes showing no measurable fatigue property degradation when tested per ASTM D7791. The heat-affected zone remains localized to under 0.05 mm depth, preserving structural integrity.

Material finish dramatically affects marking results. Anodized surfaces provide excellent contrast and clean edges, while mill-finish materials often require deeper processing for adequate visibility. Medical device components maintain their passivated surface properties when laser parameters are properly controlled.

Design Takeaway: Specify anodized or passivated finishes when laser marking is planned. For critical applications, request material compatibility testing during prototyping to verify marking quality meets your visibility and durability requirements.

Can You Combine Laser Engraving with CNC Machining?

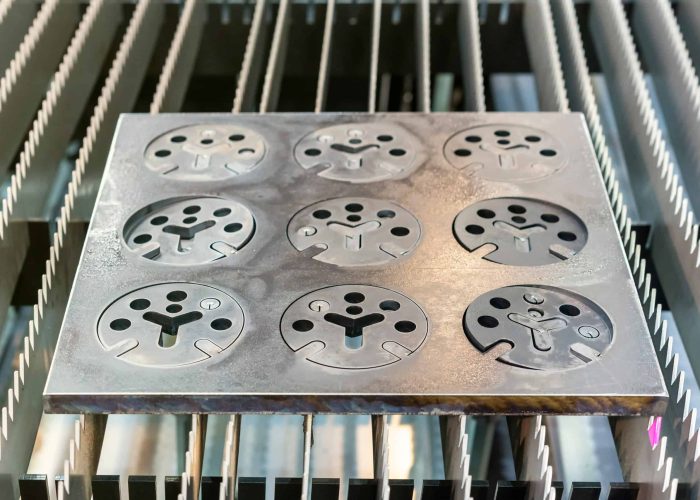

Yes, laser engraving integrates seamlessly with CNC workflows. Most applications perform laser engraving after machining to ensure marking accuracy on finished surfaces.

The timing question comes up constantly with our customers. Do the laser work first, or machine first? For most parts, laser engraving after CNC machining makes sense because you’re working with finished, dimensionally stable surfaces. No worries about thermal distortion affecting your tolerances.

The exception is when you need deep engraved features that will get partially machined away later. Maybe you’re creating a recessed logo that needs clean, machined edges around the perimeter. In those cases, rough laser the shape first, then CNC the final edges to spec.

Fixturing becomes simpler when you laser after machining because you can use the machined surfaces as references. Serial numbers end up exactly where your drawing shows them relative to holes and edges. If you laser first, you’re working off raw stock that might shift slightly during the CNC operations.

Setup consolidation depends on your shop. If you’ve got both capabilities on the same machine, great—one setup, both operations. Most shops run them separately, which means thinking through how parts transfer between operations without losing position.

Design Takeaway: Plan laser engraving after final machining for most applications to ensure dimensional accuracy. Consider pre-machining laser work only when subsequent CNC operations will improve the engraved feature geometry.

How Much Does Laser Engraving Cost and Affect Lead Time?

Laser engraving costs $5-15 per part versus $15-30 for CNC engraving, with minimal lead time impact. Volume economics favor laser above 50 pieces due to consistent processing speeds.

The cost difference comes down to setup time. CNC engraving needs tool changes, program modifications, and often different workholding. Laser operations use the same beam for everything—no tool changes, no wear concerns, no cutting fluid mess.

For small batches under 25 pieces, the cost difference isn’t dramatic. You might save a few dollars per part, but it’s not make-or-break money. Once you hit 50+ pieces, the savings start adding up because laser processing time stays consistent while CNC operations accumulate more setup overhead.

Lead time impact is usually minimal—maybe an extra day or two. The advantage is flexibility. Laser operations don’t tie up your machining centers, so they can run parallel to other work. No fighting for machine time or waiting for the right cutting tools to become available.

The volume sweet spot depends on complexity. Simple serial numbers work at any quantity. Complex graphics or artistic features need enough pieces to justify the programming time, usually 25+ parts minimum.

Design Takeaway: Specify laser engraving for quantities above 50 pieces where cost and time benefits outweigh reduced depth capability. Consider alternatives only for very high volumes or when deep engraving is functionally required.

How Do You Design Parts for Laser Engraving?

Create separate CAD layers for laser features, avoid details smaller than 0.1 mm, and submit vector-based files for optimal results. Design success depends on proper file preparation and material finish selection.

The biggest mistake we see is treating laser features like machined pockets in CAD. Don’t model them as solid extrusions—use sketches instead. This keeps your CNC toolpaths clean and gives the laser programmer flexibility to adjust parameters without rebuilding your part model.

File format matters more than you’d expect. Vector files (DXF, AI, PDF) scale perfectly and maintain clean edges. Raster images (JPG, PNG) turn into pixelated messes when scaled or create unpredictable results during processing.

Character sizing is critical for legibility. Anything under 0.5 mm tall becomes hard to read, especially on textured surfaces. Line weights under 0.1 mm either disappear entirely or come out inconsistent depending on material properties.

Font choice affects success rates dramatically. Stick with simple, sans-serif fonts with consistent stroke widths. Fancy script fonts and thin serifs look great on screen but turn into blurry messes in the real world, especially at small sizes.

Sharp corners create problems because laser beams have physical diameter. Features requiring truly sharp internal corners need post-laser CNC cleanup, which defeats the cost advantage. Plan for slight corner radii in your design.

Design Takeaway: Submit vector artwork files with dedicated CAD layers for laser features. Plan text sizing and spacing based on your material finish capabilities rather than trying to match CNC feature resolution.

Conclusion

Laser engraving offers precise marking capabilities that complement CNC machining workflows, providing cost-effective identification and decorative features for most materials. Choose laser for shallow marking under 0.3 mm and volumes above 50 pieces to maximize cost and lead time benefits. Contact us to explore manufacturing solutions tailored to your laser engraving and CNC machining requirements.

Frequently Asked Questions

Vector formats (DXF, AI, PDF) provide best results. Avoid raster images (JPG, PNG) which create pixelated edges and unpredictable scaling results during processing.

No. Laser engraving creates minimal heat-affected zones (under 0.05 mm) and doesn’t introduce mechanical stress that could distort critical dimensions or affect machined tolerances.

Typically $5-15 per part for standard marking. Volume discounts apply above 50 pieces. Compare this to $15-30 for CNC engraving when considering your marking requirements.

Yes, most coating processes. Laser engraving works well after anodizing, passivation, and powder coating. Avoid on chrome plating due to potential delamination issues around engraved areas.

0.5 mm character height provides reliable legibility across most materials and viewing conditions. Smaller text often becomes illegible, especially on textured or mill-finish surfaces where contrast is limited.

Yes. Laser engraving removes anodizing locally to create high-contrast markings without affecting surrounding areas. The process doesn’t compromise corrosion resistance of unmarked surfaces.