Designing with steel isn’t just about strength—it’s about understanding how iron content affects corrosion, magnetism, and machinability in your parts. With over 15 years machining steel components for aerospace, medical, and industrial applications, we’ve learned that steel’s ferrous classification directly impacts every design decision from surface treatments to tolerance specifications.

Steel is classified as ferrous because iron (Fe) comprises over 98% of its composition, creating predictable magnetic properties, corrosion behavior, and weldability characteristics that affect part performance and manufacturing cost.

Learn to choose the right steel grade, avoid design mistakes, and optimize for both performance and manufacturing efficiency.

Table of Contents

What's the cheapest steel grade that won't rust outdoors?

Galvanized 1018 carbon steel costs $3-4/lb versus $8-12/lb for stainless steel while providing 15-25 years outdoor protection. Hot-dip galvanizing creates a zinc barrier that prevents rust formation on the underlying steel, making it the most cost-effective option for outdoor applications.

We’ve measured galvanized coatings lasting 8+ years in coastal environments with 3% salt exposure, compared to bare 1018 steel which shows surface rust within 2-3 weeks. Galvanized parts maintain structural integrity while developing a protective patina that actually slows further corrosion. Testing shows a coating thickness of 2-4 mils (0.002-0.004″) on typical CNC parts.

For outdoor brackets, enclosures, and mounting hardware, galvanized 1018 outperforms alternatives like zinc-plated steel (2-3 year lifespan) or powder-coated carbon steel (depends on coating integrity). The key limitation is coating thickness variation – parts with deep recesses or complex internal features may not coat uniformly, creating potential corrosion start points.

Design Takeaway: Choose galvanized 1018 for outdoor parts prioritizing cost over appearance. Account for 0.004″ coating thickness in critical dimensions, or specify post-galvanizing machining for precise fits.

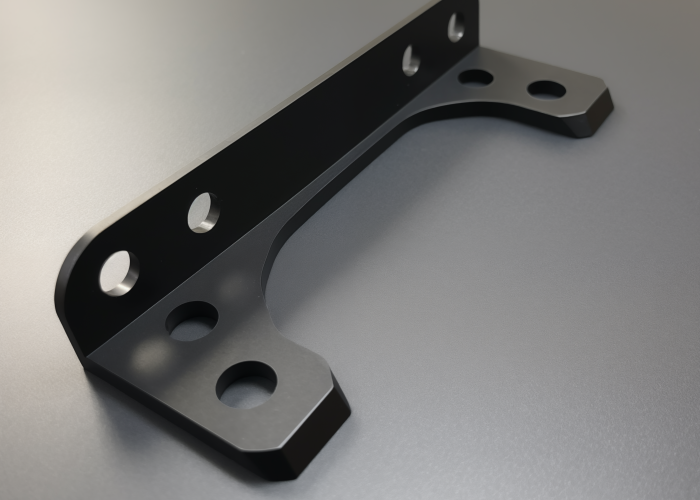

Should I use 1018 or 4140 for high-stress brackets?

Use 4140 when stress calculations exceed 30,000 PSI or for any dynamic/vibration loading. For static brackets under 25,000 PSI, 1018 saves 30-40% on material costs with no performance penalty. Most mounting brackets, equipment stands, and enclosure supports fall into the 1018 category unless you’re dealing with heavy machinery or safety-critical applications.

In our experience, 90% of bracket applications we machine are static loads well under 20,000 PSI – perfect for 1018. Robot arm brackets, conveyor supports, and equipment mounts typically see 10,000-15,000 PSI maximum. We only recommend 4140 for applications like press frames, crane components, or suspension parts where failure means injury or equipment damage. If your bracket just holds a motor or control panel in place, 1018 handles it easily.

The quick test: if your bracket experiences continuous vibration, impact loading, or supports human weight, specify 4140. If it’s bolted in place holding static equipment, 1018 works fine. For outdoor static brackets, galvanized 1018 costs half as much as stainless and lasts 15+ years.

Design Takeaway: Static indoor brackets under 500 lbs → 1018. Vibrating equipment, outdoor heavy loads, or safety-critical → 4140. When in doubt, send us your load specs and we’ll recommend the right grade.

However, of all ferrous materials, steel stands out due to its unique combination of properties, versatile applications, and relative abundance.

When does stainless steel justify the extra cost?

Choose stainless steel if your part touches food, gets wet daily, or faces chemical exposure. For dry indoor applications, galvanized or powder-coated carbon steel costs 60-70% less with equivalent performance. The break-even point is simple: will coating failure create safety, regulatory, or replacement headaches?

Kitchen equipment, medical devices, and marine hardware always justify stainless – the regulatory and safety risks make material cost irrelevant. We machine food processing brackets, pharmaceutical enclosures, and boat hardware where stainless is non-negotiable. But for office equipment, indoor electronics, or warehouse brackets, customers waste money specifying 304 when powder-coated 1018 lasts decades indoors.

The quick decision: if it’s outdoors near saltwater, touches consumables, or needs frequent washdown → stainless steel. If it’s indoors supporting static equipment → coated carbon steel. Pool equipment is the gray area – chlorinated environments usually require stainless for any wetted parts.

Design Takeaway: Food/medical/marine → always stainless. Dry indoor brackets → coated carbon steel saves 60%+ with no downside. Unsure about your environment? Describe the application and we’ll recommend the most cost-effective material.

What steel works best for parts that need welding?

For welding, use 1018 carbon steel or 304 stainless – both weld easily with standard techniques. Avoid 4140 alloy steel unless you can preheat and post-weld heat treat, as it’s prone to cracking and requires specialized procedures. The carbon content and alloy additions determine weldability more than strength or cost.

In our shop, 80% of welded assemblies use 1018 because it welds with any process (MIG, TIG, stick) without preheating or special filler metals. Fabricated frames, brackets with gussets, and multi-piece enclosures all use 1018 for consistent results. When customers need corrosion resistance plus welding, 304 stainless works perfectly but requires argon shielding and slower travel speeds. We’ve seen 4140 weld failures on brackets and frames because customers skipped the heat treating – the hardened zone becomes brittle and cracks under load.

The quick rule: structural welding for equipment stands, mounting frames, or brackets → 1018. Welding plus outdoor/chemical exposure → 304 stainless. High-strength parts → use bolted connections with 4140 pieces instead of trying to weld them. Kitchen equipment frames, conveyor structures, and machinery guards all work perfectly with welded 1018.

Design Takeaway: 1018 for 90% of welded applications – cheap, reliable, any welder can handle it. 304 stainless when environment demands it. Redesign to avoid welding 4140 – use bolted joints instead. Planning a welded assembly? Send the design and we’ll flag any weldability issues before cutting metal.

How do I avoid magnetic interference in electronic housings?

Use 300-series stainless steel (304, 316) for housings within 6 inches of magnetic sensors or precision electronics. These grades have magnetic permeability under 1.02, while carbon steel creates interference fields up to 12 inches away from sensitive components. Aluminum is non-magnetic but provides no EMI shielding for RF-sensitive circuits.

We machine housings for proximity sensors, Hall effect encoders, and medical devices where even small magnetic fields cause false readings. Carbon steel brackets near magnetic encoders create 2-3 degree position errors – discovered this on a robotic assembly that kept missing pick positions. MRI equipment housings, electronic compass cases, and precision measurement instruments all require 304 stainless to prevent field distortion. The 6-inch rule comes from testing magnetic field strength around steel components.

The material trade-off: 304 stainless costs 2-3x more than aluminum but handles both magnetic interference and EMI shielding in one solution. Aluminum housings need separate copper mesh or conductive coatings for RF protection, adding complexity and cost. For simple limit switches or basic proximity sensors, aluminum works fine if you keep steel fasteners 3+ inches away.

Design Takeaway: Magnetic sensors, encoders, or precision electronics → 304 stainless within 6 inches, aluminum okay beyond that distance. Simple on/off sensors → aluminum saves money. Carbon steel interferes up to 12 inches away from sensitive components. Need help determining safe distances? Describe your sensor layout and we’ll recommend materials by location.

Will basic carbon steel hold up for threaded connections?

1018 carbon steel holds threads fine for standard fasteners, but upgrade to 4140 for high-torque applications over 50 ft-lbs or when threads get frequent use. Thread failure usually comes from insufficient engagement length or over-torquing, not base material weakness.

The critical spec is thread engagement: minimum 1.5x bolt diameter for reliable holding power. So 1/4-20 screws need at least 0.375″ thread depth, while 10-32 needs 0.188″ minimum. We machine access panels, equipment covers, and maintenance doors with 1018 threads that handle years of assembly cycles. Thread stripping typically happens when customers exceed recommended torque values – like cranking 1/4-20 screws past 15 ft-lbs in thin sections.

For thin walls under 0.25″, consider Helicoil inserts or switch to thru-bolts with nuts. Blind holes should be drilled 2x diameter deep to account for tap breakage and ensure full engagement. Metric threads follow the same 1.5x engagement rule but use different tap drill sizes.

Design Takeaway: Standard assembly torques under 30 ft-lbs → 1018 handles it easily. Thin sections under 1.5x diameter → use inserts or thru-bolts. High-torque clamping → upgrade to 4140. Need help calculating thread engagement for your wall thickness? Send your fastener specs and we’ll verify the math.

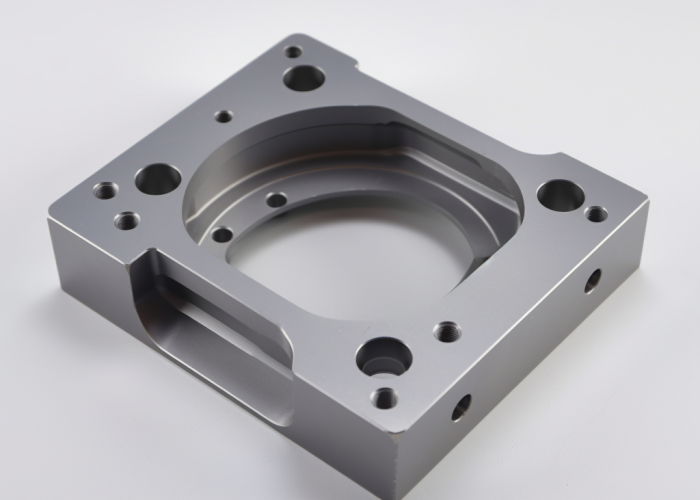

What steel grade gives me the best machinability vs strength balance?

For prototype and low-volume work, 1018 carbon steel cuts 40% faster than alternatives while delivering 65,000+ PSI tensile strength – perfect for brackets, housings, and structural parts where cycle time matters more than ultimate performance. The speed advantage reduces both machining cost and lead time significantly.

Our typical cycle time comparison: 1018 roughing at 200 IPM, 4140 at 120 IPM, 304 stainless at 80 IPM with carbide tooling. For rush prototypes or tight budgets, 1018’s machinability advantage often outweighs the strength benefits of premium alloys. Tool life extends 2-3x compared to harder materials, reducing setup interruptions and tooling costs on longer runs.

Free-machining 12L14 cuts even faster than 1018 but can’t be welded reliably – fine for turned parts like shafts or spacers, problematic for fabricated assemblies. The quantity break-even point: under 100 pieces, optimize for machining speed. Over 500 pieces, material properties matter more than cycle time differences.

Design Takeaway: Rush prototypes and small quantities → 1018 minimizes lead time and cost. Production volumes over 500 pieces → consider upgraded materials for long-term performance. Turned parts only → 12L14 for maximum speed. Balancing timeline vs performance for your project? Share your quantity and deadline – we’ll recommend the most efficient approach.

Conclusion

Steel grade selection comes down to matching material properties with your specific application requirements – corrosion exposure, stress levels, and manufacturing priorities. When cost matters most, galvanized 1018 handles 90% of applications effectively. Contact us to explore manufacturing solutions tailored to your steel component requirements.

Frequently Asked Questions

Steel threaded holes handle torque based on fastener strength, not base material. Use 6-8 ft-lbs maximum for 1/4-20 machine screws in any steel grade. Ensure 1.5x bolt diameter thread engagement minimum – 1/4-20 needs 0.375″ thread depth for reliable holding power without stripping.

Machine simple brackets from solid 1018 for prototypes – often more cost-effective than welding setup. Complex multi-piece designs benefit from welded 1018 fabrication. Avoid welding 4140 unless heat treatment capability exists. Material choice affects manufacturing method recommendation.

Steel threads strip from insufficient engagement depth or exceeding torque specifications. Ensure minimum 1.5x bolt diameter thread engagement and stay within fastener torque limits (6-8 ft-lbs for 1/4-20). Thin walls under 0.25″ require Helicoil inserts or thru-bolt designs.

Keep carbon steel brackets beyond 12 inches from magnetic sensors to prevent interference. Hall effect sensors, encoders, and proximity switches give false readings when steel components create magnetic fields within their detection range. Use 304 stainless or aluminum for sensor mounts requiring closer placement.

Hot-dip galvanized 1018 carbon steel costs $3-4/lb versus $8-12/lb for stainless steel while providing 15-25 years outdoor corrosion protection. The zinc coating prevents rust formation with 0.004″ thickness that must be accounted for in critical dimensions.

4140 alloy steel with 180,000+ PSI tensile strength provides adequate safety margin for 40,000 PSI stress applications. 1018 carbon steel at 65,000 PSI tensile strength operates too close to yield strength for reliable performance. The 30-40% material cost increase prevents failure in high-stress brackets and structural components.