Hard anodizing decisions directly impact part performance, cost, and manufacturing timeline in precision CNC projects. After processing thousands of aluminum components for aerospace, medical, and industrial applications, small specification changes can dramatically affect both component durability and production costs.

These 15 questions cover critical hard anodizing decisions: material selection, dimensional compensation, cost analysis, tolerance requirements, and inspection methods. Each provides specific data on hardness values, thickness ranges, and specification requirements for CNC aluminum projects.

Learn specification requirements, tolerance considerations, and performance data to make informed hard anodizing decisions for your aluminum components.

Table of Contents

What Hardness Does Hard Anodizing Achieve on 6061 Aluminum?

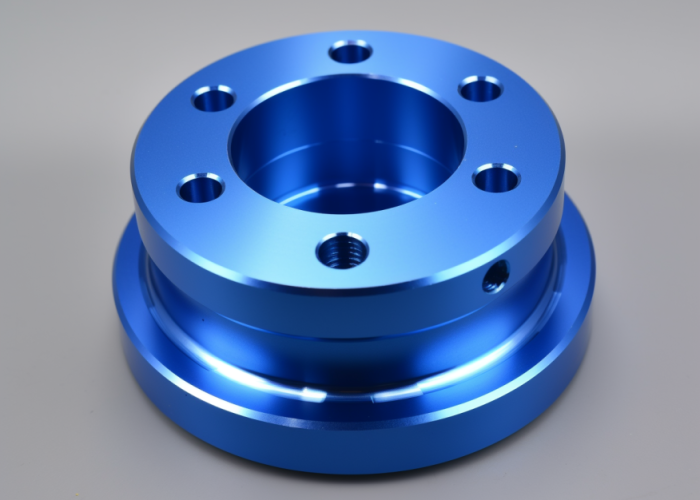

Hard anodizing makes 6061 aluminum as hard as tool steel (60-70 HRC). This solves galling, thread seizing, and wear groove problems in metal-contact applications. Costs $2-5 per square foot extra versus standard anodizing.

Your real decision: Is aluminum wearing against other metals in your design?

Common problems hard anodizing fixes:

- Knob shafts wearing grooves in aluminum panels

- Aluminum threads seizing in steel assemblies

- Pivot pins creating play/looseness over time

- Linear slides developing friction and binding

When you don’t need it:

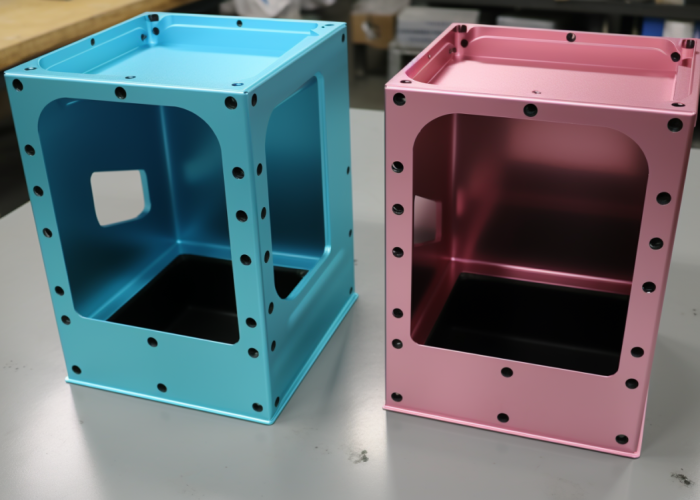

- Aluminum housings/covers that don’t touch other parts

- Internal brackets with no moving contact

- Decorative panels or trim pieces

Quick cost check: Calculate your part’s square footage and multiply by $2-5. A 4″×6″ panel costs $0.35-0.85 extra for hard anodizing. Worth it if wear would cause warranty issues or require steel inserts.

Design trap to avoid: Hard anodizing grows 0.0005″-0.001″ thick. Threaded holes will be undersized, press-fits won’t work. Either machine undersized initially or mask critical features (adds cost).

Design Takeaway: If your aluminum touches other metals during use, hard anodizing prevents wear problems that would otherwise require design changes. If nothing touches it, save the money and use standard anodizing.

Which Aluminum Alloy Works Best for Hard Anodizing?

Use 6061-T6 for 90% of hard anodizing applications. Only choose 7075 if your part carries structural loads AND needs wear resistance. 6061 costs 40% less, machines faster, and produces identical surface hardness.

Simple decision framework:

Does your part carry structural loads (bending, tension, mounting forces)?

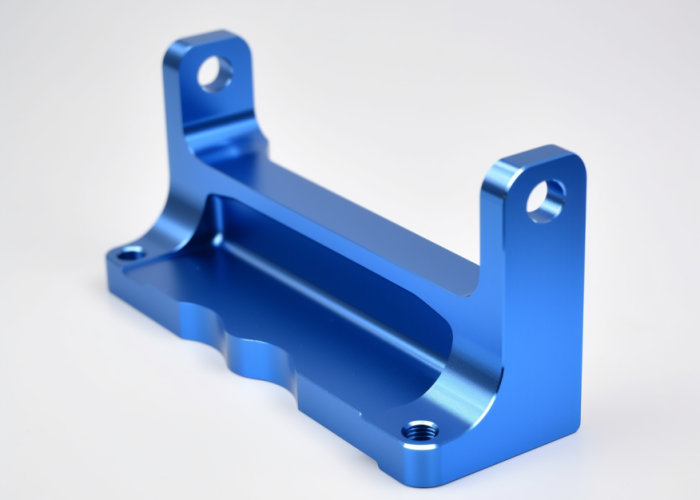

- No → 6061-T6 (knobs, faceplates, pivot pins, slides)

- Yes → Does it also have metal-contact wear issues?

- No wear contact → Use 6061, skip hard anodizing entirely

- Both structural + wear → 7075 (structural brackets with pivot points)

Cost impact on your project:

- 6061 bar stock: $3-5/lb + standard machining rates

- 7075 bar stock: $5-8/lb + 20% longer machining time

Real example: Audio equipment faceplate with knob mounting points. 6061 hard anodizing prevents knob shaft wear grooves with no performance benefit from 7075 since the faceplate carries no structural loads.

Design Takeaway: Start with 6061-T6. Only upgrade to 7075 if your stress analysis shows you need its strength AND you have wear problems. Don’t pay 40% extra for strength you don’t need.

How Much Does Hard Anodizing Cost Per Square Inch?

Quick budget check: Surface area × $0.025 = rough anodizing cost. If this is under 20% of your part’s total cost, hard anodizing usually makes sense. If over 50%, consider design alternatives.

Instant cost calculator:

- Measure part length × width × 2 (for panels) = square inches

- Multiply by $0.025 for budget estimate

- Add $100-250 setup fee ÷ number of parts in your batch

Budget decision framework:

- Under $5 per part → Usually worth it vs. design alternatives

- $5-15 per part → Compare to steel insert costs ($8-15 each)

- Over $15 per part → Redesign to eliminate wear contact instead

Volume economics:

- 5-20 prototypes: $15-50 each (setup costs dominate)

- 100+ production: $2-8 each (true per-square-inch rates)

When to skip hard anodizing: If your calculation shows >$20 per part, consider coating + design changes, steel bushings, or eliminating metal contact through redesign.

Design Takeaway: Calculate costs early in design phase. Batch multiple parts together to split setup fees. If anodizing exceeds 25% of total part cost, explore design alternatives that eliminate the need for wear resistance.

How Much Thickness Does Hard Anodizing Add to Parts?

Hard anodizing adds about 0.001″ thickness that will break threaded assemblies and press-fits unless you plan for it. If your part has critical fits or threads, machine them 0.001″ oversized before anodizing. If it’s just a panel or housing, thickness won’t affect function.

Will this break your design?

Yes – you need to plan for growth:

- Threaded holes → Standard threads won’t assemble after anodizing

- Press-fit bearings/pins → Interference becomes too tight to install

- Precision mating surfaces → Parts won’t fit together properly

- Gasket grooves → Seals won’t seat correctly

No – thickness doesn’t matter:

- Decorative panels → No functional impact on appearance or mounting

- Non-critical clearance holes → Still plenty of clearance for fasteners

- General enclosures → Doesn’t affect assembly or function

- Mounting brackets → Bolt holes and surfaces work fine

Simple solution for critical features: Machine threaded holes 0.001″ oversized before anodizing (use #7 drill instead of #21 for 1/4-20 threads). Machine press-fit shafts 0.001″ undersized. This costs nothing extra and prevents assembly problems.

When you can ignore it: If your part is basically a shaped piece of aluminum without precision fits – panels, brackets, housings – the thickness growth won’t cause functional problems.

Design Takeaway: Check if your part has threaded assemblies or precision fits. If yes, adjust those features 0.001″ during design. If no, proceed with standard dimensions – the thickness won’t affect your design.

Can Hard Anodized Parts Maintain Threaded Holes and Press-Fits?

Yes, but you must plan ahead. Choose: machine undersized initially (costs nothing), mask critical features ($0.25-1.00/sq inch), or re-work after anodizing ($25-50 per part). Planning during design phase eliminates expensive fixes.

Threaded holes – your options:

Best: Machine oversized initially → Use tap drill 0.001″ larger than standard. Example: #7 drill (0.201″) instead of #21 drill (0.159″) for 1/4-20 threads. Costs nothing extra.

Alternative: Mask threads → Prevents anodizing in threaded areas. Costs $0.25-0.50 per hole but maintains exact thread specs.

Last resort: Re-tap after anodizing → Removes anodizing from threads but maintains function. Costs $2-5 per hole in labor.

Press-fits – your decision:

Best: Machine shaft undersized → No extra cost, maintains designed interference fit.

Alternative: Mask press-fit surfaces → Keeps exact dimensions but adds masking cost.

Won’t work: Hope it fits anyway → Growth turns manageable interference into impossible assembly.

Cost comparison for typical part:

- Design compensation: $0 extra

- Masking 4 holes + 2 press-fits: $8-15

- Post-anodizing re-work: $25-50

Design Takeaway: Plan critical features during design phase. Machine threaded holes 0.001″ oversized and press-fit shafts undersized. This costs nothing and eliminates post-anodizing problems.

What Tolerances Can Hard Anodizing Hold on CNC Parts?

Hard anodizing can hold ±0.002″-0.003″ on most features, but adds 0.001″ thickness that affects your design tolerances. Use ±0.005″ tolerances when possible, or specify “critical dimensions after anodizing” on drawings for tighter specs.

Tolerance strategy for your drawings:

±0.005″ tolerances: Hard anodizing easily stays within spec. Use this whenever possible – it’s the most cost-effective approach with no special requirements.

±0.002″ tolerances: Achievable but specify “after anodizing” on your drawings. This tells the machinist to hit final dimensions after the anodizing process, not before.

±0.001″ tolerances: Requires masking critical surfaces or post-anodizing machining. Budget extra cost for these approaches.

Drawing callout examples that work:

- “±0.005 TYPICAL, ±0.002 AFTER ANODIZING WHERE NOTED”

- “MACHINE 0.001″ UNDERSIZED FOR ANODIZING COMPENSATION”

- “MASK SURFACES MARKED ‘M’ DURING ANODIZING”

When tight tolerances matter: Mating surfaces, bearing bores, and precision assemblies need careful tolerance planning. Non-critical dimensions like overall length or mounting hole locations can use standard ±0.005″ tolerances.

Cost impact of tolerance choices: ±0.005″ tolerances: No extra cost ±0.002″ tolerances: Possible extra inspection, minimal cost ±0.001″ tolerances: Masking ($0.25-1.00/sq inch) or post-machining ($50-150 setup)

Design Takeaway: Default to ±0.005″ tolerances on anodized parts. Only specify tighter tolerances where functionally required, and include “after anodizing” callouts on drawings to ensure proper execution.

Does Hard Anodizing Affect Thermal Conductivity and Heat Transfer?

Hard anodizing slightly reduces thermal conductivity but provides electrical isolation that’s often more valuable than maximum heat transfer. Most thermal designs work fine with hard anodizing – validate performance through thermal modeling if heat transfer is critical.

Will thermal reduction affect your design?

Electronics applications: The electrical isolation benefits usually outweigh thermal reduction. Hard anodizing prevents ground loops and electrical shorts that could damage components.

Heat sink applications: Hard anodizing prevents galling between aluminum heat sinks and mounting hardware, maintaining long-term thermal contact better than bare aluminum that can corrode or wear.

Critical thermal applications: If your thermal analysis shows you’re already close to temperature limits, consider masking primary heat transfer surfaces while anodizing the rest for corrosion protection.

Design approach: Include hard anodizing in your thermal models from the start. Size heat sinks slightly larger if thermal margin is tight, rather than trying to optimize around anodizing limitations afterward.

Audio amplifier heat sinks perform adequately with full hard anodizing. The electrical isolation prevents ground loops, and thermal performance remains sufficient for normal operation.

Design Takeaway: Include hard anodizing in your thermal models early. The electrical and wear benefits usually justify the minor thermal trade-off, but validate performance before finalizing the design.

How Do I Specify Hard Anodizing on Engineering Drawings?

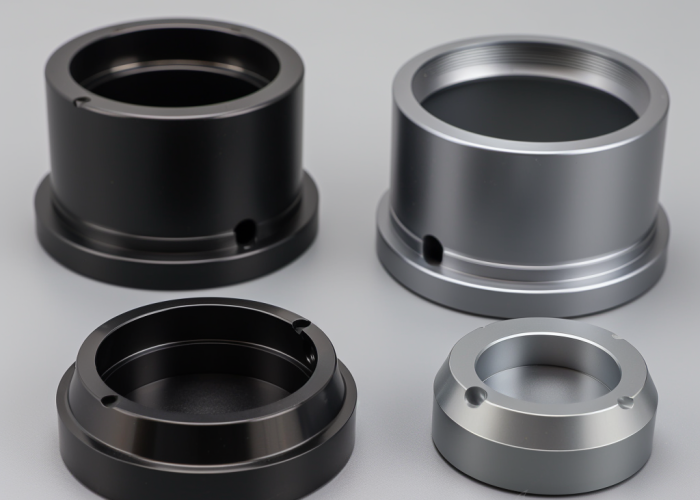

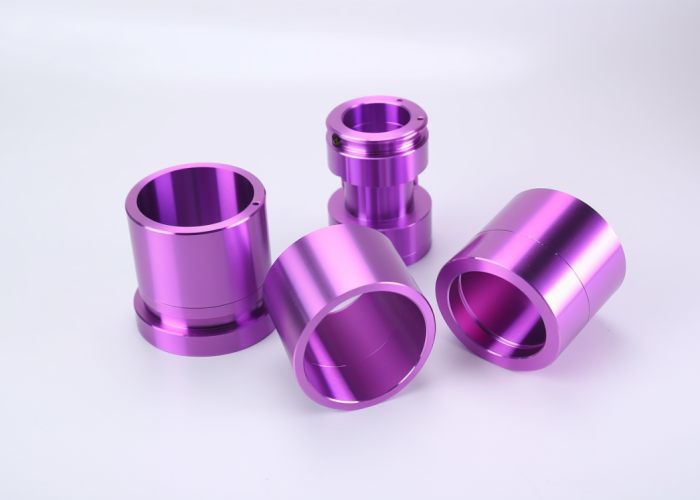

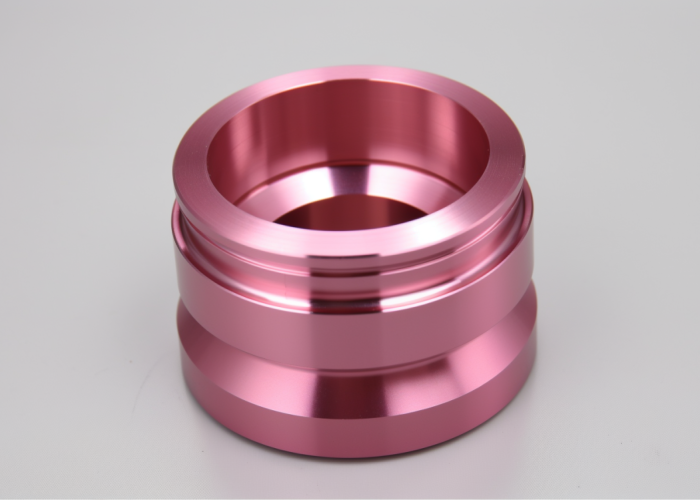

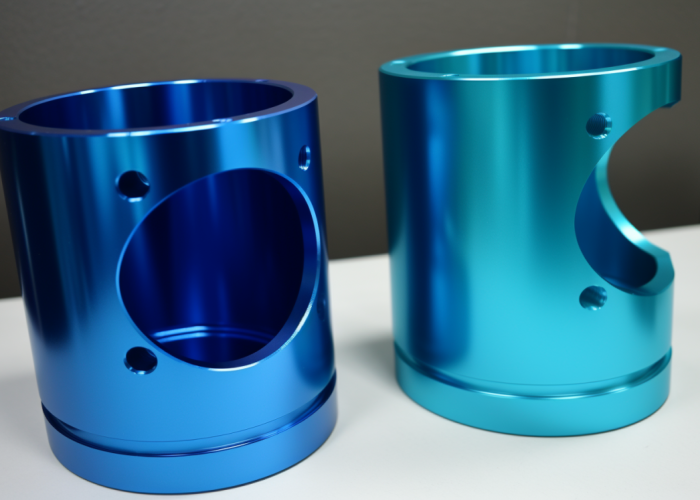

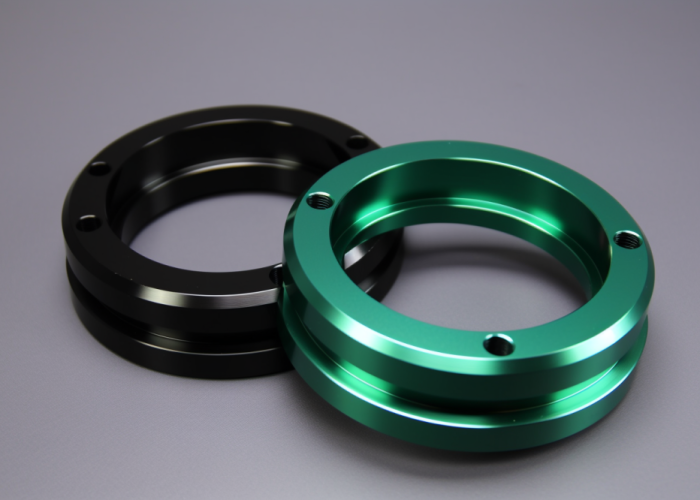

Specify “MIL-A-8625 Type III Class 2” for standard hard anodizing, or “Hard Anodize per ASTM B580″ for commercial applications. Include thickness callouts (0.0005″-0.001”), color requirements (typically black), and mark critical features with “M” symbols for masking.

Essential drawing callouts for hard anodizing:

Process specification: “HARD ANODIZE PER MIL-A-8625 TYPE III CLASS 2” (military/aerospace) or “HARD ANODIZE PER ASTM B580” (commercial applications).

Thickness requirement: “ANODIZE THICKNESS 0.0007″ ±0.0002″” or “0.5-1.0 MIL THICK” depending on your application needs.

Color specification: “BLACK DYED” or “NATURAL (CLEAR)” – black is most common for wear applications.

Critical dimension callouts:

- “DIMENSIONS SHOWN AFTER ANODIZING”

- “MACHINE 0.0008″ UNDERSIZED FOR ANODIZING COMPENSATION”

- Mark surfaces to be masked with “M” symbol and note “MASK DURING ANODIZING”

Drawing note examples:

- “BREAK ALL SHARP EDGES 0.005-0.015 BEFORE ANODIZING”

- “ANODIZE ALL SURFACES UNLESS OTHERWISE NOTED”

- “RE-TAP THREADS AFTER ANODIZING IF REQUIRED”

Quality requirements: Add “HARDNESS 60-70 HRC” if hardness verification is needed for your application.

Design Takeaway: Use standard specifications (MIL-A-8625 Type III) and clearly mark masked features. Include thickness and color requirements. Specify whether dimensions are before or after anodizing to prevent machining mistakes.

Can Hard Anodized Parts Meet Smooth Surface Finish Requirements?

Hard anodizing roughens surfaces to Ra 40-50 μin, making it unsuitable for sealing applications or smooth aesthetics without extra finishing. If your part needs smooth surfaces, consider standard anodizing + coating, or budget 2x extra cost for post-anodizing polishing.

Should you proceed with hard anodizing?

Proceed when:

- You can accept Ra 40-50 μin matte finish for your application

- Wear resistance is more important than surface smoothness

- You have budget for post-anodizing finishing ($0.50-1.00/sq inch extra)

Choose alternatives when:

- Sealing surfaces require Ra 32 μin or better (gasket grooves, O-ring bores)

- Aesthetic appearance needs smooth, polished look

- Multiple surfaces need finishing (costs multiply quickly)

- Tight project budget can’t absorb finishing costs

Alternative approaches for smooth + durable surfaces:

- Standard anodizing + polyurethane coating (smooth finish, good wear)

- Chrome plating (expensive but very smooth and hard)

- Electroless nickel (smooth finish, excellent wear resistance)

Cost reality check: Post-anodizing polishing often costs more than the hard anodizing itself. For parts with extensive smooth surface requirements, redesigning to eliminate those requirements or choosing alternative processes may be more cost-effective.

Design decision: If smooth surfaces are critical to function or appearance, hard anodizing adds significant cost and complexity. Consider whether wear resistance justifies the extra finishing operations.

Design Takeaway: Hard anodizing works best when surface texture isn’t critical. For smooth surface requirements, evaluate whether alternative processes or design changes provide better cost-performance balance than hard anodizing + finishing.

10. When Should I Require Hard Anodizing Inspection?

Require inspection for safety-critical or high-wear applications where coating failure could cause problems. Skip inspection for non-critical parts where standard anodizer quality control is adequate. Inspection adds $2-5 per part but prevents costly field failures.

Application Type Require Inspection? Why Cost Impact

Medical devices, aerospace Yes Coating failure = safety risk $3-5/part vs. liability costs

High-wear bearings, slides Yes Thickness affects service life $3-5/part vs. $50+ replacement

Production validation Yes – first articles Verify process capability One-time validation cost

Housings, covers, brackets No Defects only affect appearance Save $3-5/part

Prototype parts No Focus budget on design iteration Save 50%+ on part cost

Trusted vendor relationship Maybe Reduce after quality established Gradual cost reduction

Design Takeaway: Require inspection when coating failure creates significant cost, safety, or performance risk. For non-critical applications, anodizer quality control is usually sufficient.

Will Hard Anodizing Delay My Project Schedule?

Hard anodizing adds 2-3 weeks to your timeline compared to standard finishes. Plan this early in project scheduling or choose faster alternatives. Rush service costs 50-75% extra and may not be available during busy periods.

Project Situation Timeline Impact Recommended Action Alternative Options

Design phase planning Plan 2-3 weeks Include in initial schedule None needed

Trade show <6 weeks Will likely delay Use standard anodizing Coating, painting (1-5 days)

Prototype iterations Too slow for rapid cycles Standard anodizing for early prototypes Switch to hard anodizing for final

Production batching Manageable Batch multiple parts together None needed

Emergency repairs Not compatible Choose faster process Standard anodizing, coating

Rush timeline 50-75% extra cost Evaluate if budget allows Faster alternatives

Design Takeaway: Factor 2-3 weeks into project timelines from the start. For tight schedules, consider whether standard anodizing + coating provides adequate performance at faster turnaround.

What's the Minimum Order Quantity for Hard Anodizing?

Most hard anodizing shops require $100-250 minimum batch charges, which typically covers 20-100 small parts or 5-20 larger components. Single prototype parts cost $50-125 each due to setup economics, making batching essential for cost control.

Minimum order economics by part size:

Part Size Typical MOQ Cost Per Part When It Makes Sense

Small parts (<10 sq in) 50-100 pieces $2-5 each Production runs

Medium parts (10-50 sq in) 20-50 pieces $5-15 each Pilot production

Large parts (>50 sq in) 5-20 pieces $15-50 each Prototypes, low volume

Single prototypes 1 piece minimum $50-125 each Development only

Batching strategies to reduce costs:

Multi-part batching: Combine different part numbers in single batch to share setup costs. Works well for product families or related components.

Timing coordination: Accumulate parts over several weeks to build full batches rather than processing individually.

Design family approach: Design multiple variants to use same anodizing specification, enabling larger batch quantities.

When small quantities make sense:

- Critical prototype validation where coating performance must be tested

- Emergency replacement parts where lead time matters more than cost

- High-value components where anodizing cost is small percentage of total

Volume planning for production: Plan production quantities around anodizing batch economics. Sometimes ordering 100 parts instead of 75 reduces per-piece cost significantly.

Design Takeaway: Plan part quantities around $200-300 batch minimums to optimize anodizing costs. For prototypes, budget $50-100 per part or batch multiple projects together to share setup costs.

What If I Need to Modify Parts After Hard Anodizing?

You can fix most problems, but it’s expensive and removes coating protection. Evaluate repair cost vs. starting over – often remaking parts is more cost-effective than extensive post-anodizing modifications.

Quick decision check: Is it a simple fix or major rework?

Simple fixes – usually worth it:

- Re-tapping tight threaded holes: $2-5 per hole

- Drilling additional mounting holes: $10-25 per hole

- Opening press-fit bores slightly: $15-30 per feature

- Minor material removal: $50-150 setup plus machining time

Major rework – usually remake:

- Multiple features need changes

- Overall dimensional corrections

- Extensive material removal

- Complex geometry modifications

When to fix instead of remake:

- Small quantities (1-10 parts) where setup costs hurt

- High-value parts where material cost is significant

- Tight timeline where remaking causes project delays

- Simple modifications that don’t compromise coating integrity

When to remake instead of fix:

- Large quantities (20+ parts) where economics favor new parts

- Extensive modifications that remove most of the protective coating

- Multiple changes that multiply machining costs

- Customer design changes affecting overall part function

Quality impact of modifications: Modified areas lose anodizing protection and may corrode differently than untouched surfaces. Consider this for outdoor or harsh environment applications.

Cost reality: Post-anodizing machining often costs more than the original anodizing process. Factor this into your decision – sometimes starting over is cheaper.

Design Takeaway: Evaluate each situation based on modification complexity, quantity, and timeline. Simple fixes are usually worthwhile, but extensive rework often justifies starting over with corrected parts.

Do Threaded Holes Work After Hard Anodizing?

Threaded holes become too tight for proper assembly after hard anodizing unless you plan ahead. Use tap drill 0.003-0.005″ oversized before anodizing, mask threads during processing, or re-tap after anodizing to maintain thread function.

Thread function after hard anodizing:

Thread Planning Method Assembly Result Cost Impact When to Use

Standard tap drill Too tight – won’t assemble Requires re-tap ($2-5/hole) Never recommended

Oversized tap drill (+0.003-0.005″) Perfect fit after anodizing No extra cost Best choice for new designs

Mask threads during anodizing Exact original thread specs $0.25-0.50/hole masking Critical tolerance threads

Re-tap after anodizing Functional but no coating $2-5/hole labor Fix for existing problems

Planning threaded holes for hard anodizing:

New designs: Use tap drill 0.003-0.005″ larger than standard. For 1/4-20 threads, use #3 drill (0.213″) instead of #7 drill (0.201″). This costs nothing extra and maintains thread function after anodizing buildup.

Critical tolerance threads: Mask during anodizing to maintain exact thread specifications. Necessary for precision assemblies or when thread coating might interfere with function.

Thread types that need special attention:

- Fine pitch threads (more affected by thickness buildup)

- Blind holes (harder to re-tap if needed)

- Long engagement threads (cumulative thickness effect)

Communication with anodizer: Clearly specify which threads need masking vs. which can be re-tapped. Mark thread requirements on drawings to prevent confusion.

Design Takeaway: Always plan for 0.003-0.005″ thread growth during hard anodizing. Use oversized tap drills for new designs, mask critical threads, or budget for re-tapping existing parts.

How Do I Know If My Hard Anodized Parts Are Good Quality?

Good hard anodizing appears uniform dark gray to black with consistent matte finish. Reject parts with bare aluminum spots, white/chalky areas, or severe color variation. Minor color differences on complex geometries are usually acceptable.

Quality inspection checklist when parts arrive:

Accept as good quality:

- Uniform dark gray to black color (exact shade varies by alloy)

- Consistent matte, non-reflective finish

- Minor color variation on edges or complex geometry

- Small tool marks from handling/racking

- Slight thickness variation in deep pockets

Reject as defective:

- Bare aluminum spots (bright metallic areas)

- White, chalky, or burned-looking areas

- Severe color variation or streaking on flat surfaces

- Coating that chips or flakes with normal handling

- Missing coating in critical wear areas

Functional vs. cosmetic quality standards:

Critical wear surfaces: Must have full, uniform coating – reject any bare spots or significant thinning that affects wear resistance.

Visible aesthetic surfaces: Minor color variation may be acceptable depending on application – consistent appearance more important than perfect uniformity.

Hidden functional surfaces: Focus on coating presence rather than appearance – slight color variation doesn’t affect performance.

Documentation for consistent standards: Photo examples of acceptable vs. unacceptable quality prevent future confusion and help maintain consistent expectations across orders.

Design Takeaway: Focus inspection on defects that actually affect your part’s performance. Establish clear functional vs. aesthetic requirements and document acceptable quality standards with visual examples.

Conclusion

Hard anodizing transforms aluminum components into high-performance engineering solutions through careful design planning. While material selection, dimensional compensation, and surface requirements need consideration, proper specification ensures exceptional wear resistance and durability for demanding applications. Contact us to explore manufacturing solutions tailored to your hard anodizing requirements.

Frequently Asked Questions

Standard lead time is 2-3 weeks. Rush service (3-5 days) costs 50-75% extra and isn’t always available. For tight timelines, consider standard anodizing (5-7 days) or coating alternatives.

Good hard anodizing appears uniform dark gray/black with consistent matte finish. Reject parts with bare aluminum spots, white/chalky areas, or severe color streaking. Minor color variation on complex geometry is normal.

Mask dissimilar materials during anodizing to prevent coating defects. Steel inserts can cause uneven coating nearby. Plan masking locations during design phase and communicate requirements clearly to anodizer.

No, coating adhesion to hard anodized surfaces is poor and may fail. Use standard anodizing for better paint/coating adhesion, or skip anodizing entirely if the coating provides adequate protection.

Hard anodizing adds 0.001″ thickness that wasn’t compensated in design. Either re-machine critical features (expensive) or remake parts with proper dimensional compensation. Plan this during design phase next time.

Hard anodizing costs 2-3x more but provides 4x the hardness. Worth it for metal-contact applications like pivot pins, slides, or threaded interfaces where wear is a concern. Skip it for non-contact housings or decorative panels.