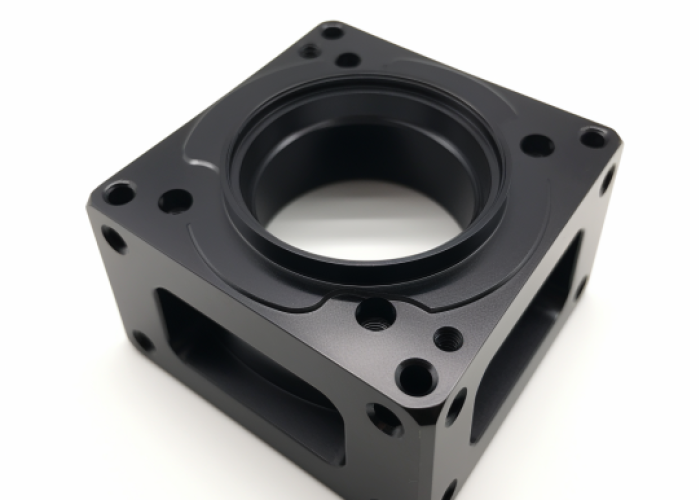

Choosing between blind holes and through holes affects part strength and manufacturing cost. With experience machining precision components for aerospace, medical, and industrial applications, Okdor helps engineers make decisions that balance functionality with cost-effective manufacturing.

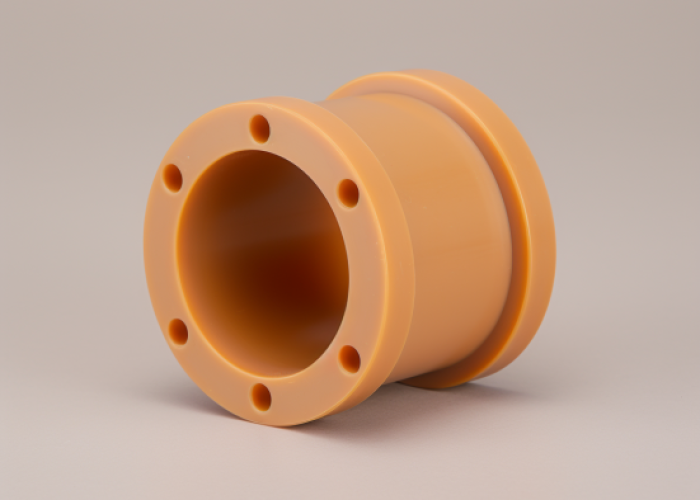

A blind hole stops at a specified depth without penetrating the material, maintaining structural integrity while providing controlled access for fasteners or components. Typical depth tolerances range from ±0.05mm to ±0.01mm depending on application requirements and machining setup.

Learn optimal depth specifications, cost comparisons with through holes, and design tips to avoid common machining problems in precision applications.

Table of Contents

When Should You Use a Blind Hole Instead of a Through Hole?

Choose blind holes when you need to maintain structural integrity, avoid breakthrough on visible surfaces, or create secure fastener locations. Through holes work better for complete penetration, drainage, or two-sided assembly access.

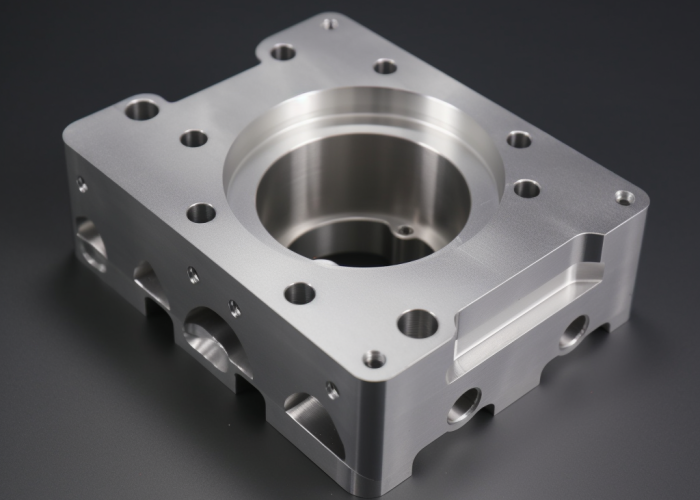

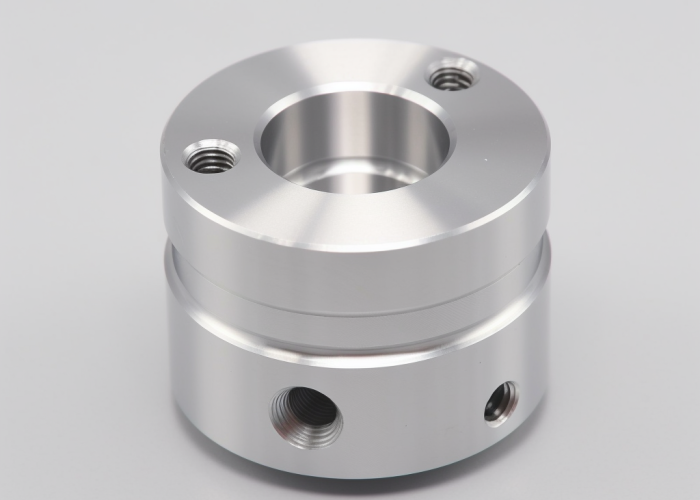

The key difference comes down to what happens to your material. Blind holes preserve the full thickness on one side, which matters more than most engineers realize. In aluminum housings, we maintain ±0.01mm depth tolerance while preserving 85% more material cross-section compared to through holes. This prevents stress concentrations that cause cracking under vibration loads.

Medical device applications require blind holes for ISO 13485 compliance – they eliminate contamination pathways that through holes create. We verify this using CMM inspection to ensure no breakthrough occurs. Audio equipment benefits similarly with better electromagnetic shielding and cleaner aesthetics on visible surfaces.

The trade-off is accessibility. Through holes let you reach fasteners from both sides, which simplifies assembly. They’re also essential when you actually need complete penetration – like drainage ports or cable routing where airflow is required.

Design Takeaway: Pick blind holes when you want to preserve surface integrity and structural strength. Use through holes when you need complete penetration or two-sided assembly access.

Do Blind Holes Cost More Than Through Holes to Machine?

Blind holes typically add 20-30% to machining cost due to specialized tooling and chip evacuation time, but eliminate secondary finishing operations that through holes require.

The extra cost comes from machining complexity. Blind holes need peck drilling cycles to clear chips and depth-stop tooling for precise control. We’ve measured this adds 2-3 minutes per hole in aluminum components compared to straight-through drilling at 1500 RPM. However, through holes often need exit-side deburring and surface finishing that blind holes avoid.

In stainless steel medical housings, blind holes actually reduce total part cost. Through holes create exit burrs requiring secondary grinding operations, while blind holes maintain clean surfaces throughout. The machining premium gets offset by eliminated finishing steps.

Tooling costs differ too. Blind hole drills need chip-breaking geometries and shorter lengths for rigidity, costing $50-80 versus $25-35 for standard bits. But tool life often improves since there’s no breakthrough shock that damages cutting edges.

Design Takeaway: Budget 20-30% more for blind hole machining, but factor in savings from eliminated deburring and finishing operations on breakthrough surfaces.

| Blind Hole | Thru Hole | |

| Definition | Doesn’t pass through the workpiece. | Extends entirely through the material. |

| Use | For fasteners that don’t need to protrude. | For securing components on both sides. |

| Interaction | Provides an internal thread/recess. | Allows a fastener to pass through. |

Will a Blind Hole Make Your Part Stronger or Weaker?

Blind holes typically strengthen parts by maintaining material continuity on one side, avoiding the complete stress discontinuity that through holes create.

The strength advantage comes from preserved material thickness. Through holes create stress concentration at both entry and exit points, while blind holes only disrupt material flow on one side. In titanium aerospace components, this matters significantly under high loads where every bit of material cross-section counts.

We machine blind holes in surgical instruments where material removal must be minimized for strength certification. Pull-testing confirms that blind hole configurations maintain higher ultimate strength compared to through hole designs. The closed bottom distributes loads across remaining thickness rather than creating a complete void through the part.

However, blind hole geometry affects performance. Sharp corners at the hole bottom can concentrate stress under cyclic loading. We specify 0.1-0.2mm radius at hole bottoms when parts experience repeated stress cycles to prevent fatigue crack initiation.

Design Takeaway: Blind holes generally improve structural performance by maintaining material continuity. Specify radiused hole bottoms for fatigue-critical applications.

What's the Right Depth for Blind Holes in Different Applications?

Fastener blind holes need 1.5x thread diameter depth for full engagement, component seating requires exact height plus clearance, and decorative features work best at 0.3-0.8mm depth.

Thread engagement drives fastener depth requirements. M6 threads in aluminum need 9mm minimum depth for full holding power per ISO 898 specifications – deeper holes don’t improve strength but increase machining time. We verify depths using CMM measurement to ±0.02mm accuracy and maintain 1.0mm minimum bottom thickness to prevent thread breakthrough during installation.

Component seating applications need precise depth control. Circuit board standoffs require exact component height plus 0.1-0.2mm clearance for thermal expansion. We use depth-stop tooling and touch-probe verification to achieve consistent seating across production runs.

Decorative applications work differently. Logo recesses in anodized aluminum provide clear definition at 0.5mm depth while maintaining housing strength. Consumer electronics often specify this depth range for contrasting finishes that won’t compromise structural integrity.

Design Takeaway: Match blind hole depth to function – 1.5x thread diameter for fasteners, component height plus clearance for seating, 0.3-0.8mm for decorative features.

How Do You Know if Your Blind Hole Design Can Be Machined?

Check tool access, depth-to-diameter ratios, and material thickness around the hole. Blind holes deeper than 5x diameter or with insufficient wall thickness create machining challenges that increase cost and reduce accuracy.

Tool access determines machinability more than depth alone. End mills and drills need adequate clearance around the hole entry – we require minimum 2x tool diameter clearance from edges or other features. CAM software simulation helps identify interference issues before machining begins, preventing costly setup problems.

Depth-to-diameter ratios affect achievable tolerances. Holes deeper than 3x diameter require specialized long-reach tooling that’s prone to deflection and chatter. We measure runout using dial indicators during setup and verify depth using CMM touch probes to ±0.02mm accuracy. Tolerances degrade from ±0.05mm to ±0.1mm beyond 4x diameter depth due to tool flex.

Wall thickness around blind holes must support cutting forces. Minimum 1.5x hole diameter wall thickness prevents deflection during machining – we verify this using finite element analysis for critical parts. Thin walls vibrate under cutting loads, creating poor surface finish and dimensional inaccuracy. Fixture support or thicker sections solve this issue.

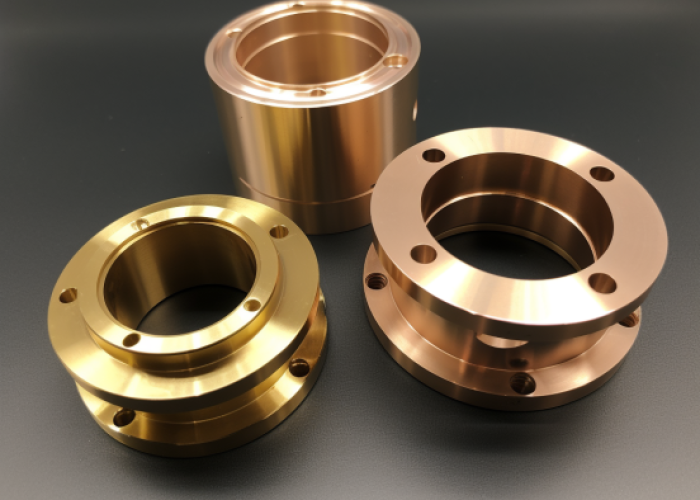

Material properties also matter. Soft materials like brass machine easily to 6x diameter depth, while harder materials like stainless steel limit practical depth to 3x diameter before tool wear becomes excessive.

Design Takeaway: Use CAM simulation to verify tool access, limit depth to 3-4x diameter for tight tolerances, and maintain 1.5x diameter minimum wall thickness. Verify critical dimensions using CMM inspection.

Can You Put Threads in Blind Holes Without Problems?

Blind hole threading works well when depth provides 1.5x thread diameter engagement and bottom clearance prevents chip jamming. Avoid threading deeper than 2x diameter to prevent tap breakage and chip evacuation issues.

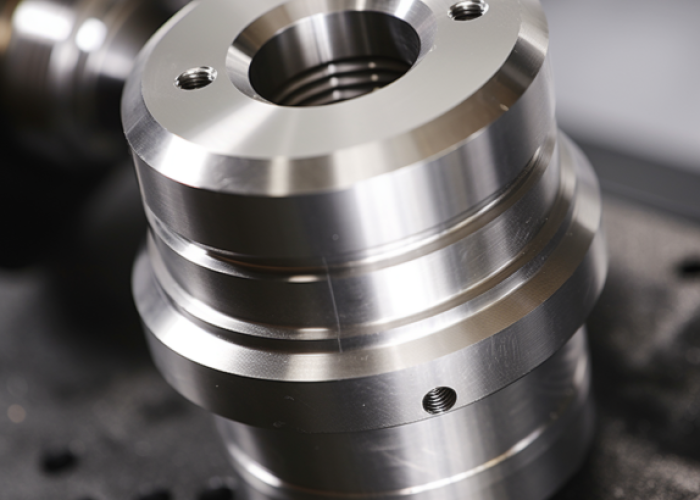

Thread engagement determines holding strength. M8 threads need 12mm minimum depth for full strength – less engagement reduces pull-out resistance significantly. We tap blind holes using spiral-point taps that push chips toward the bottom rather than pulling them out, preventing jam-ups that break taps.

Chip clearance at hole bottom is critical. Threads generate metal chips that must have somewhere to go in blind holes. We machine blind holes 2-3mm deeper than final thread depth, creating a chip pocket that prevents tap binding. Without this clearance, taps break when chips pack at the bottom.

Thread class affects success rates. Class 2B threads (standard fit) work better in blind holes than tight Class 3B threads. Tighter tolerances increase cutting forces and chip generation, making tap breakage more likely in confined blind hole spaces.

Material considerations matter for threading. Aluminum threads easily in blind holes up to 2x diameter depth. Stainless steel requires cutting fluid and slower speeds to prevent work hardening that can seize taps. We verify thread quality using go/no-go gauges after tapping.

Design Takeaway: Provide 1.5x diameter thread engagement plus 2-3mm chip clearance at bottom. Use Class 2B threads and limit depth to 2x diameter for reliable production.

How Do You Clean and Inspect Blind Holes After Machining?

Blind holes require compressed air cleaning followed by solvent flushing to remove chips and cutting fluid. Inspection uses borescopes for visual checking and CMMs for dimensional verification of depth and diameter.

Chip removal is the primary cleaning challenge. Blind holes trap metal particles and cutting fluid that gravity can’t remove. We use high-pressure compressed air (90 PSI minimum) to blow out loose chips, followed by solvent flushing with isopropyl alcohol to dissolve cutting fluid residue. Parts get inverted and tapped to help stubborn chips fall out.

Visual inspection requires borescope equipment for holes deeper than 10mm or smaller than 6mm diameter. Surface defects, tool marks, or remaining chips aren’t visible from the entry end. We check for proper hole bottom geometry, ensuring radiused corners where specified and absence of breakthrough cracks.

Dimensional inspection uses CMM equipment with touch probes small enough to reach hole bottoms. Depth measurement requires specialized probe configurations – standard CMM probes can’t reach narrow or deep blind holes. We verify depth tolerance (typically ±0.05mm) and diameter consistency from entry to bottom.

Thread inspection in blind holes uses go/no-go gauges where possible, or specialized thread micrometers for critical applications. Borescope inspection confirms thread quality at the hole bottom where tap wear typically shows first.

Design Takeaway: Specify cleaning requirements for critical applications and ensure hole geometry allows proper inspection access. Consider inspection costs when designing blind holes with tight tolerances.

Conclusion

Blind holes offer superior structural integrity and surface aesthetics compared to through holes, but require careful depth specification and machining consideration. Choose blind holes when preserving material continuity outweighs assembly convenience. Contact us to explore manufacturing solutions tailored to your blind hole requirements.

The skills in creating blind holes are invaluable across many fields. Manufacturing professionals, engineers, and DIY enthusiasts can benefit from mastering these techniques.

So, apply this knowledge in your projects and appreciate the difference it makes. Remember, every detail contributes to the success of the final product. Keep learning and creating.

Frequently Asked Questions

Blind holes eliminate breakthrough marks that through holes create, improving surface aesthetics. They’re ideal for visible surfaces where exit-side finishing would be costly or compromise appearance requirements.

Blind holes maintain higher strength than through holes by preserving material continuity on one side. However, specify 0.1-0.2mm radius at hole bottoms for fatigue-critical applications to prevent stress concentration.

Yes, specify depth tolerance (typically ±0.05mm), bottom geometry (flat or radiused), and thread engagement length if applicable. Include cleaning requirements for critical applications to ensure proper chip removal.

Maintain minimum 1.5x hole diameter wall thickness to prevent deflection during machining. Thinner walls vibrate under cutting forces, causing poor surface finish and dimensional inaccuracy requiring fixture support.

Too shallow reduces thread engagement below 1.5x diameter, causing fastener pull-out. Too deep wastes material, increases cost, and may cause tool deflection affecting accuracy without performance benefit.

Limit blind holes to 3-4x diameter depth for tight tolerances. Deeper holes require long-reach tooling prone to deflection, degrading accuracy from ±0.05mm to ±0.1mm in aluminum components.