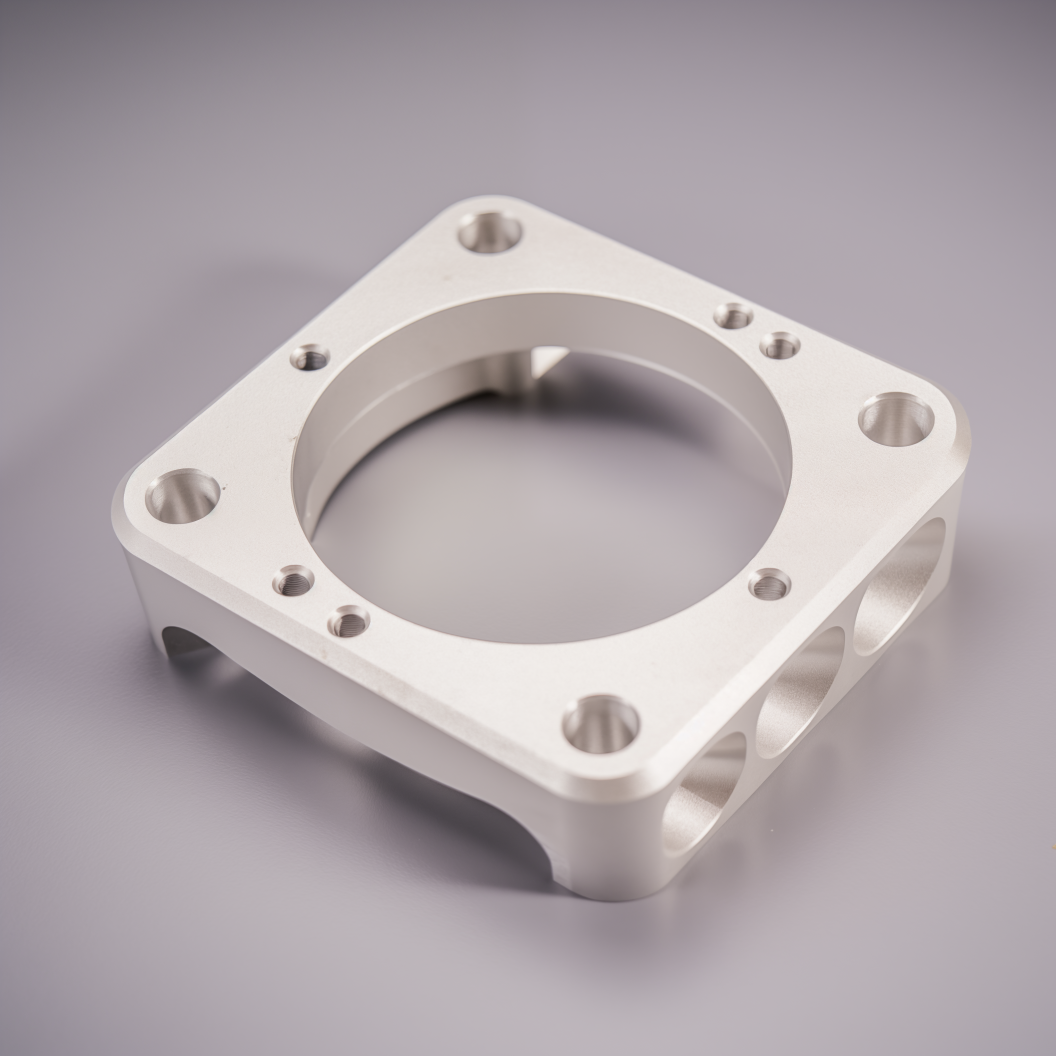

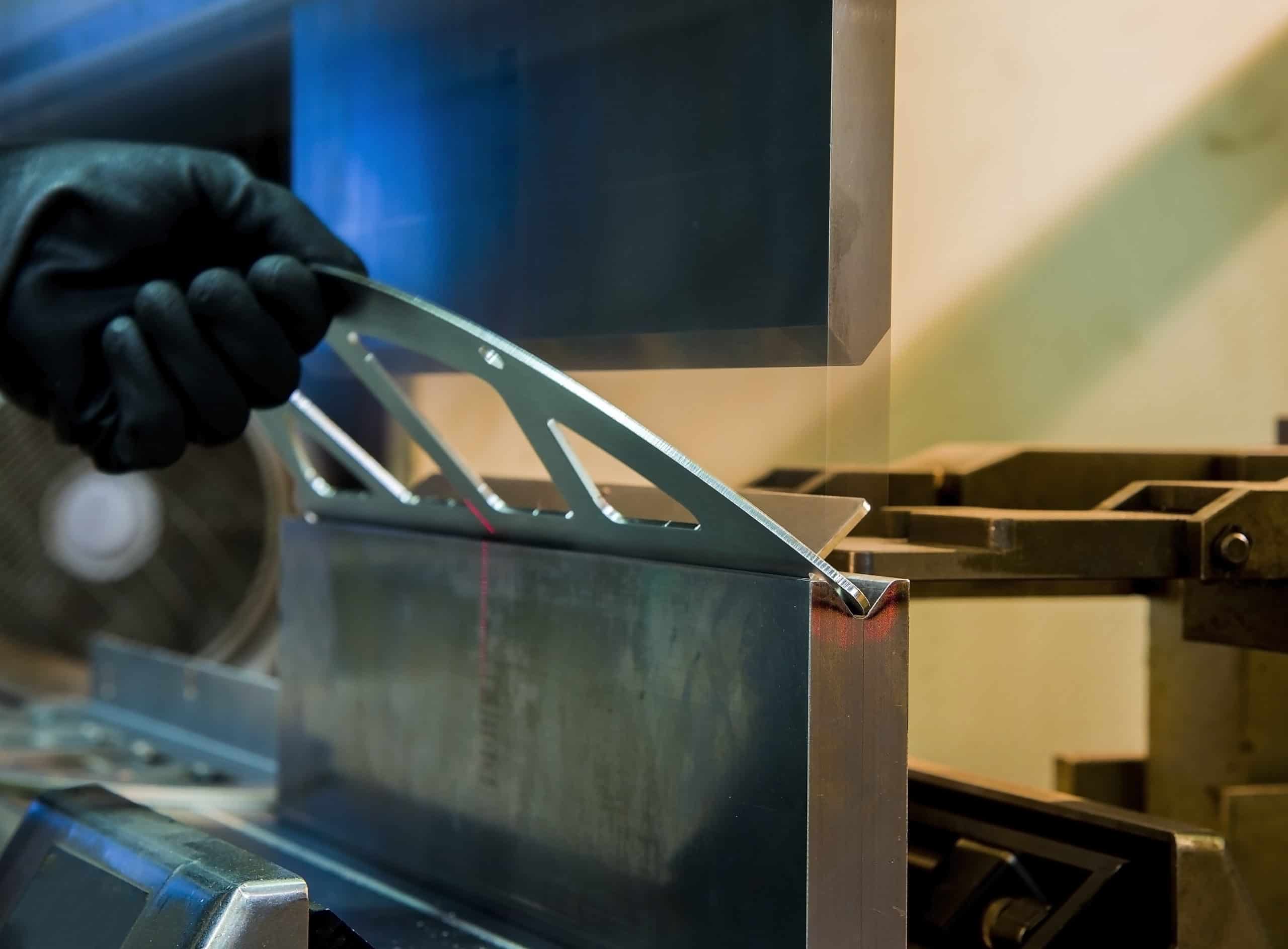

Do I Need Surface Grinding for My CNC Part?

Designing precision parts often leads to a familiar crossroads: will standard CNC machining deliver the surface you need, or must you add grinding? With experience

Designing precision parts often leads to a familiar crossroads: will standard CNC machining deliver the surface you need, or must you add grinding? With experience

Machining chatter, caused by vibrations between the tool and workpiece, leads to poor surface finish and tool damage. Overcoming it involves adjusting cutting speeds, tool

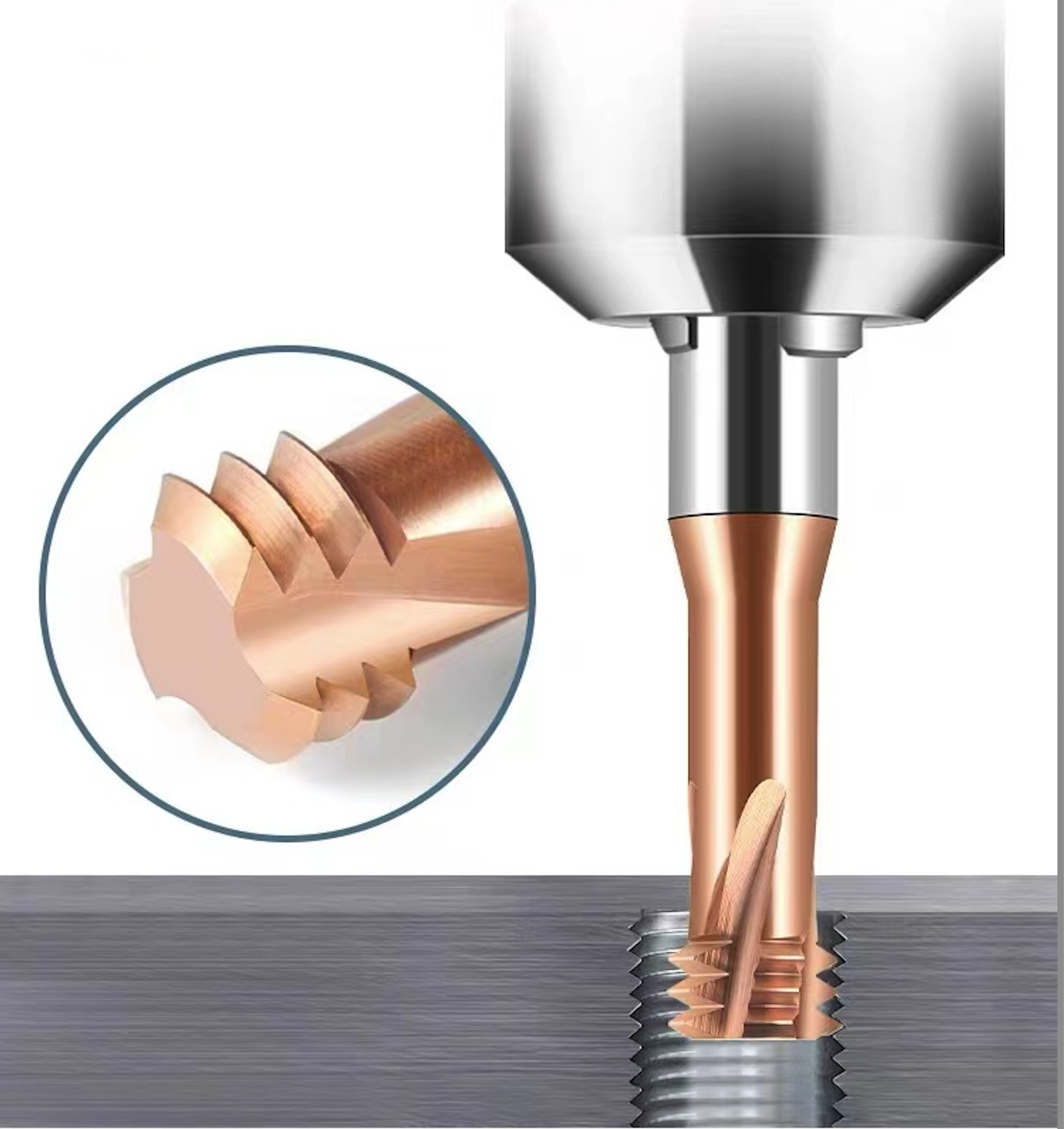

A broken screw stuck in a tap hole can turn a simple task into a major headache. But don’t despair! This guide will walk you

Silver plating durability depends on application conditions and layer thickness. With experience plating precision components for audio and medical sectors, proper specification prevents premature wear

Designing parts with curved pipe structures requires understanding which bending methods can achieve your geometry without kinking or dimensional drift. With over 15 years of

Choosing the right counterbore affects assembly function, fastener accessibility, and manufacturing cost. With experience machining precision components for aerospace, medical, and industrial sectors, small counterbore

Designing precision ABS parts requires understanding how this material behaves under CNC cutting conditions. After machining thousands of ABS components for medical devices, electronics housings,

https://okdor.com/wp-content/uploads/2023/12/ss-304-1220.mp4 Selecting 304 stainless steel for CNC projects requires understanding its application limits and machining characteristics. With decades of experience manufacturing precision parts for aerospace,

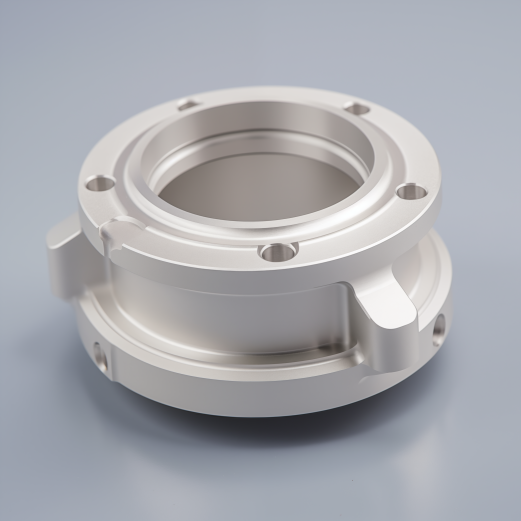

Choosing aluminum grades impacts both manufacturability and cost. After machining thousands of precision parts for aerospace, audio, and medical applications, 6061 consistently delivers the best

Choosing hardened steel for CNC parts means balancing performance needs against machining complexity and cost. From aerospace to medical applications, the right material decision impacts

The complete guide to custom manufacturing

Everything about custom manufacturing.

Collection of materials properties

Helpful tips and Advice

In a fast, efficient, and cost-effective manner, we provide services to product developers and engineers worldwide who are bringing new ideas to market.

why choose us

Order flow, from quote to deliver

How do we quote and deliver parts so fast

How we deliver consistent quality

Our team works with hundreds of specialized manufacturers so you don’t have to. Quality is guaranteed even on the most complex prototypes and parts.