What is special about surgical steel?

https://okdor.com/wp-content/uploads/2023/11/surgical-steel.mp4 Hey there! If you’ve ever wondered about the superhero of the steel world that stands strong in the face of corrosion and wear, let

https://okdor.com/wp-content/uploads/2023/11/surgical-steel.mp4 Hey there! If you’ve ever wondered about the superhero of the steel world that stands strong in the face of corrosion and wear, let

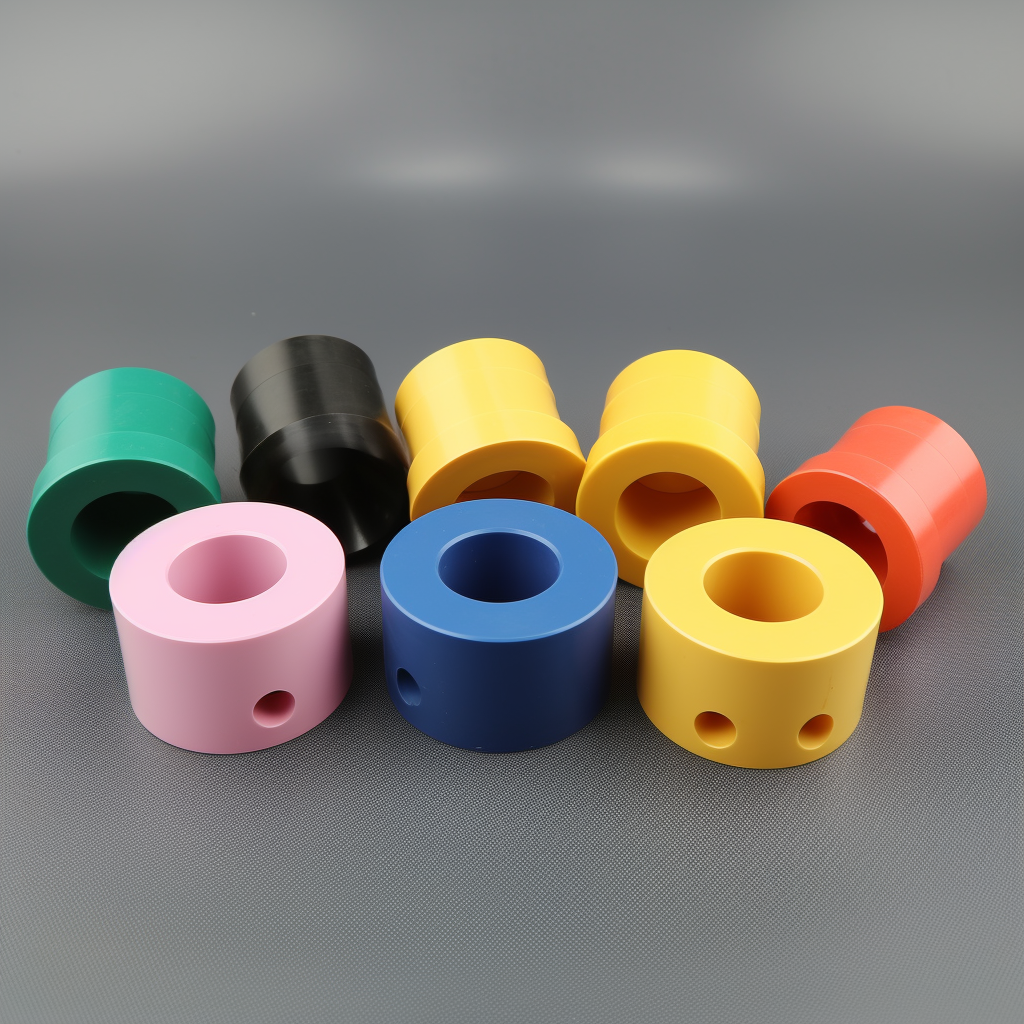

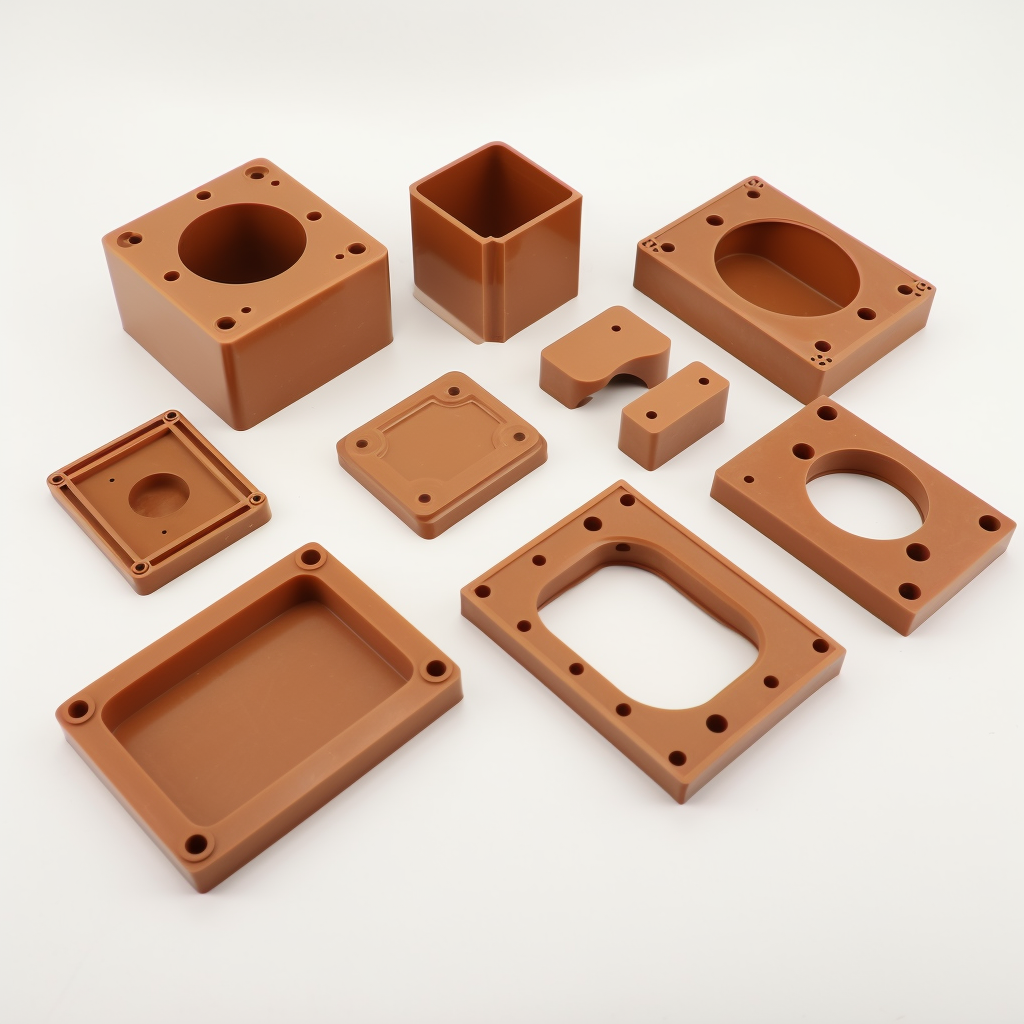

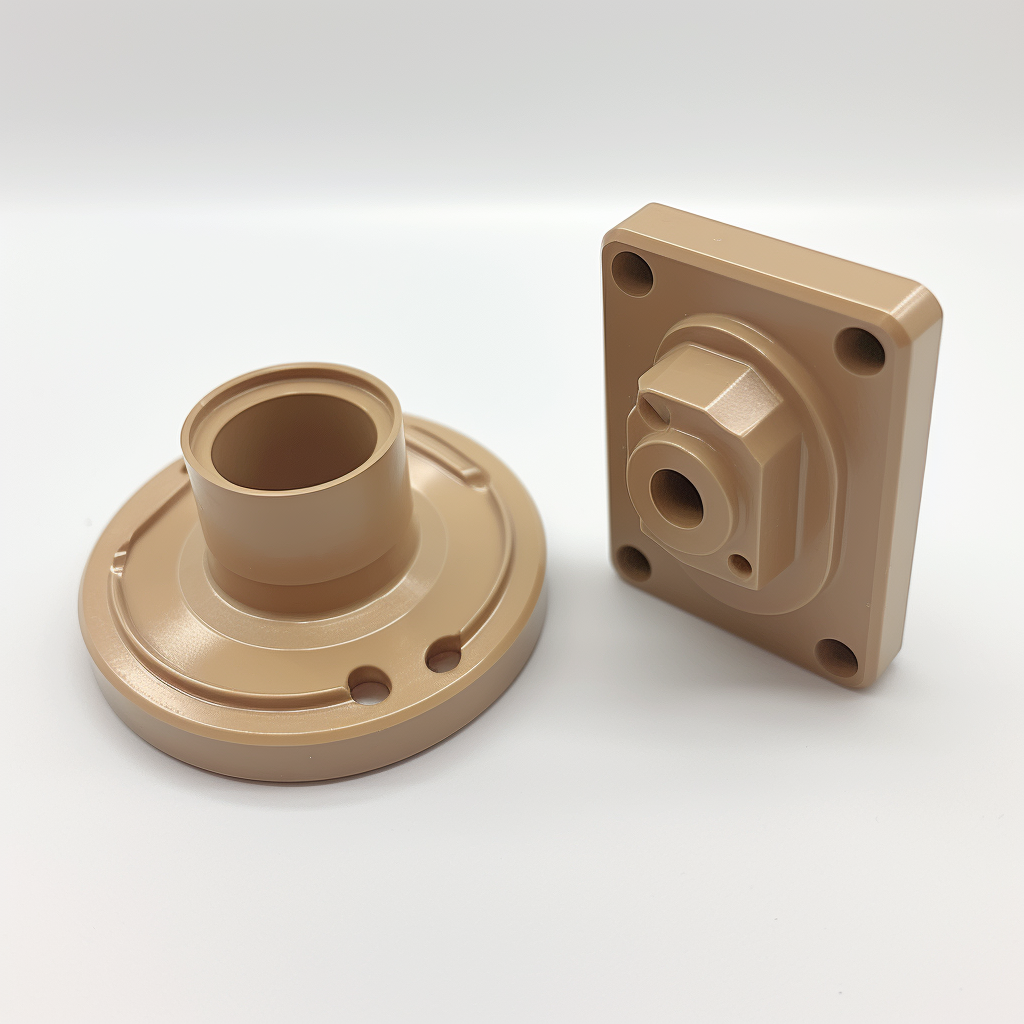

Choosing CNC plastic materials affects both part quality and production cost. After machining thousands of precision plastic components, small material decisions make huge differences in

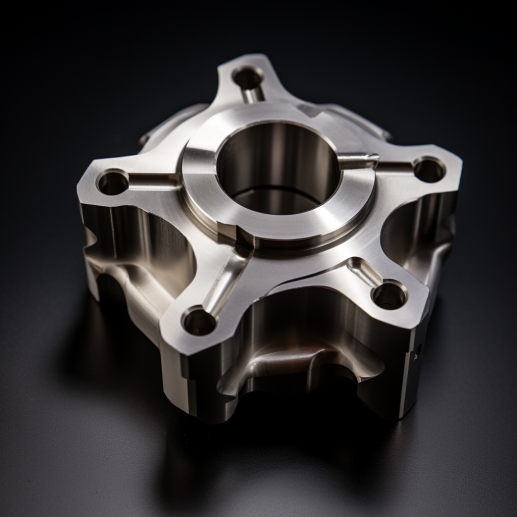

In modern manufacturing, the precision machining process is not just a method; it’s the benchmark for quality. Precision CNC machining equipment, including multi-axis CNC milling

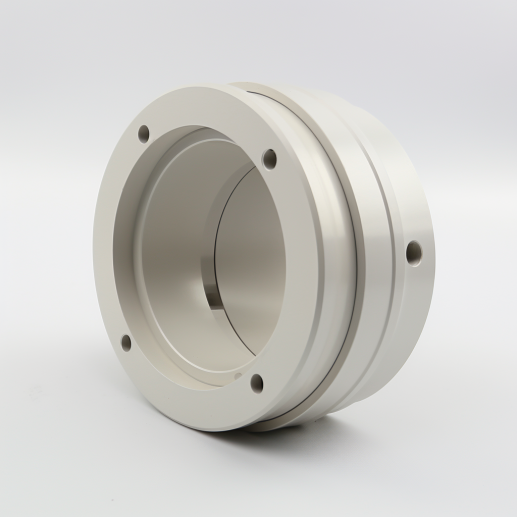

Specifying electroplating on precision parts isn’t just about corrosion resistance — it’s about understanding dimensional impact. With 15+ years finishing parts for aerospace and medical

Selecting the right finish for CNC machined parts affects corrosion resistance, assembly performance, and project costs. With over 15 years of precision machining experience across

Designing precision CNC parts for aerospace, medical, and audio applications means every micron matters. After decades of machining tight-tolerance components and applying various finishes, we’ve

Product developers often ask us which plastics work best for laser marking — and for good reason. After years of marking everything from medical device

Getting shocked by end mill machining quotes? You’re not alone. After years of machining custom parts for product developers across aerospace, audio, and medical sectors,

Choosing heat-resistant plastics for CNC components means balancing temperature limits with cost and machinability. With decades of experience machining high-temp plastics for aerospace and automotive

Spur gears aren’t always the obvious choice, but they solve cost and complexity problems that helical and bevel gears create. From medical device housings to

The complete guide to custom manufacturing

Everything about custom manufacturing.

Collection of materials properties

Helpful tips and Advice

In a fast, efficient, and cost-effective manner, we provide services to product developers and engineers worldwide who are bringing new ideas to market.

why choose us

Order flow, from quote to deliver

How do we quote and deliver parts so fast

How we deliver consistent quality

Our team works with hundreds of specialized manufacturers so you don’t have to. Quality is guaranteed even on the most complex prototypes and parts.