How Do Different Coatings Affect Aluminum Part Tolerances?

Choosing the right coating for aluminum parts isn’t just about appearance — it’s about ensuring your design still works after finishing. We’ve seen projects where coating thickness turned perfectly fitting assemblies into expensive rework. Coating adds material thickness that can break your tolerances, affect threaded connections, and compromise assembly fits. Powder coating might add 75-150 […]

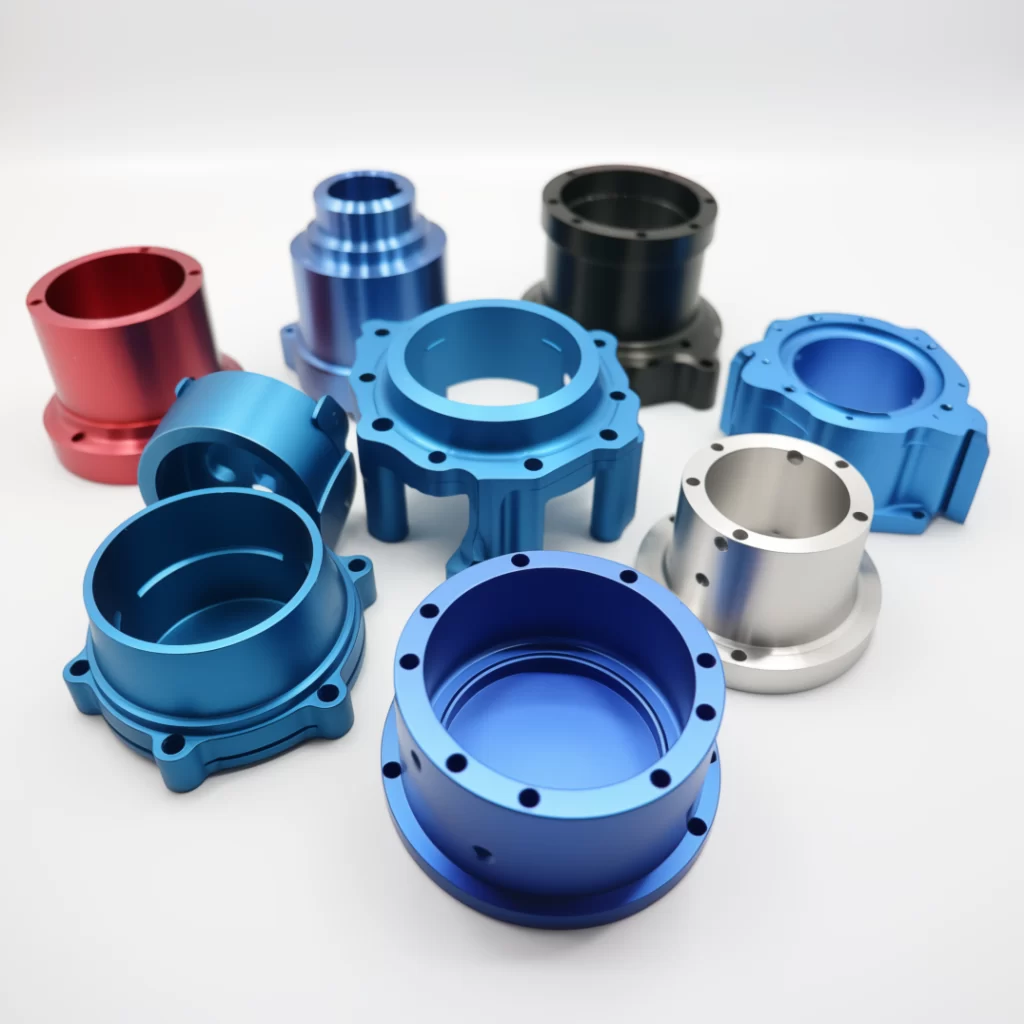

Which surface treatment is best for aluminum parts?

Selecting the right surface treatment for aluminum parts affects corrosion resistance, dimensional tolerances, and production cost. The wrong finish choice can create assembly issues or blow your budget, while the right one enhances both performance and appearance. Choose anodizing for corrosion resistance and color options, powder coating for durability and thick coverage, or bead blasting […]

Can anodizing be removed?

Anodizing removal questions arise frequently in CNC machining projects when design changes, coating defects, or rework requirements surface after parts are already anodized. As a precision CNC machining service provider, we regularly help engineers and product developers navigate anodizing removal decisions, weighing feasibility against cost and dimensional impact. Understanding removal options early prevents costly delays […]

Do I Need Surface Grinding for My CNC Part?

Designing precision parts often leads to a familiar crossroads: will standard CNC machining deliver the surface you need, or must you add grinding? With experience machining gauge blocks and precision tooling, small surface decisions can dramatically impact both function and cost. You need surface grinding when flatness requirements are tighter than ±0.02 mm, when mating […]

Does silver plating last?

Silver plating durability depends on application conditions and layer thickness. With experience plating precision components for audio and medical sectors, proper specification prevents premature wear and tarnishing issues. Silver plating typically lasts 5-15 years in indoor applications when applied at 5-25 μm thickness. Durability depends on handling frequency, environmental exposure, and base material preparation. Proper […]

Will Electroplating Mess Up My Part Tolerances?

Specifying electroplating on precision parts isn’t just about corrosion resistance — it’s about understanding dimensional impact. With 15+ years finishing parts for aerospace and medical sectors, small plating decisions can dramatically affect tolerances. Most electroplating adds 0.0002″ to 0.002″ thickness depending on the finish type and part geometry. This buildup affects press fits, threaded connections, […]

Do I Need Tin Plating for My CNC Parts?

Selecting the right finish for CNC machined parts affects corrosion resistance, assembly performance, and project costs. With over 15 years of precision machining experience across aerospace, medical, and electronics industries, we’ve helped product developers navigate finish decisions that balance protection with budget constraints. Tin plating is necessary when you need excellent solderability (tin-lead compatibility), FDA […]

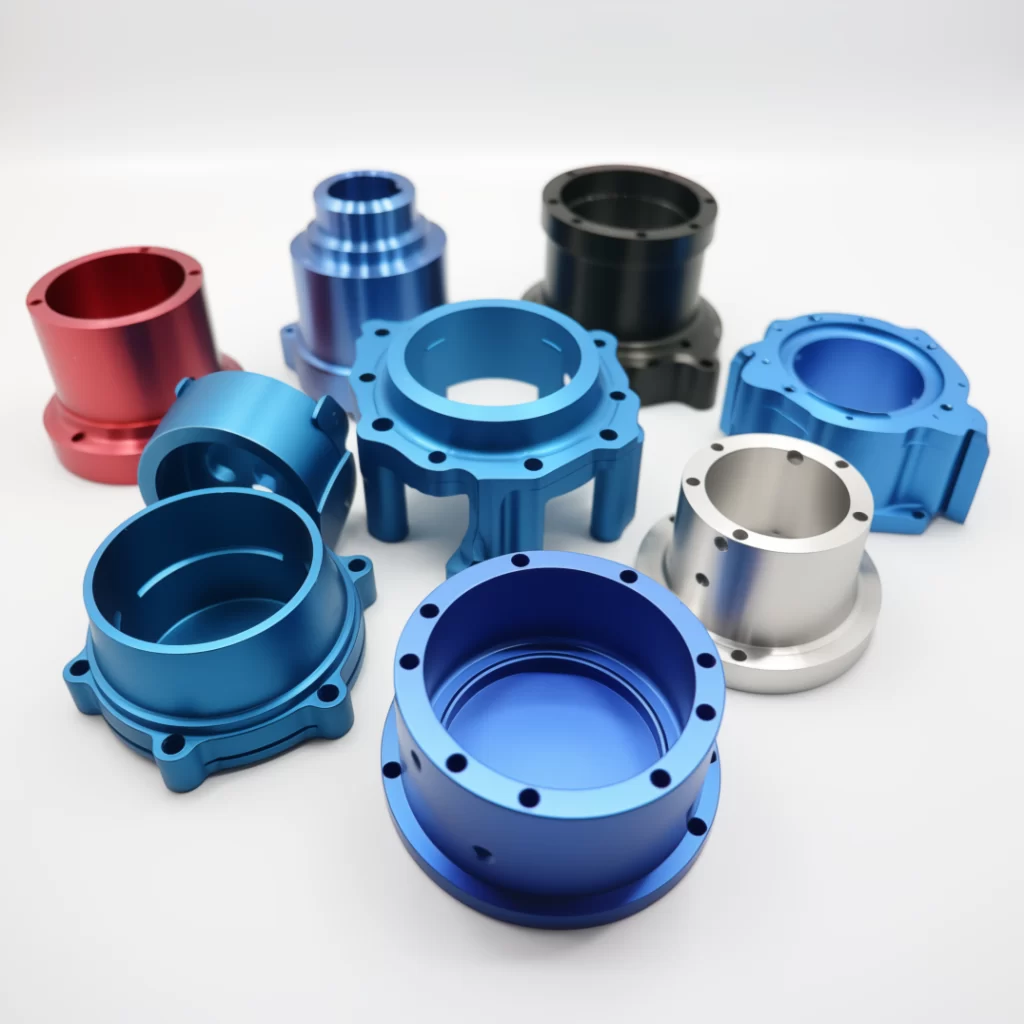

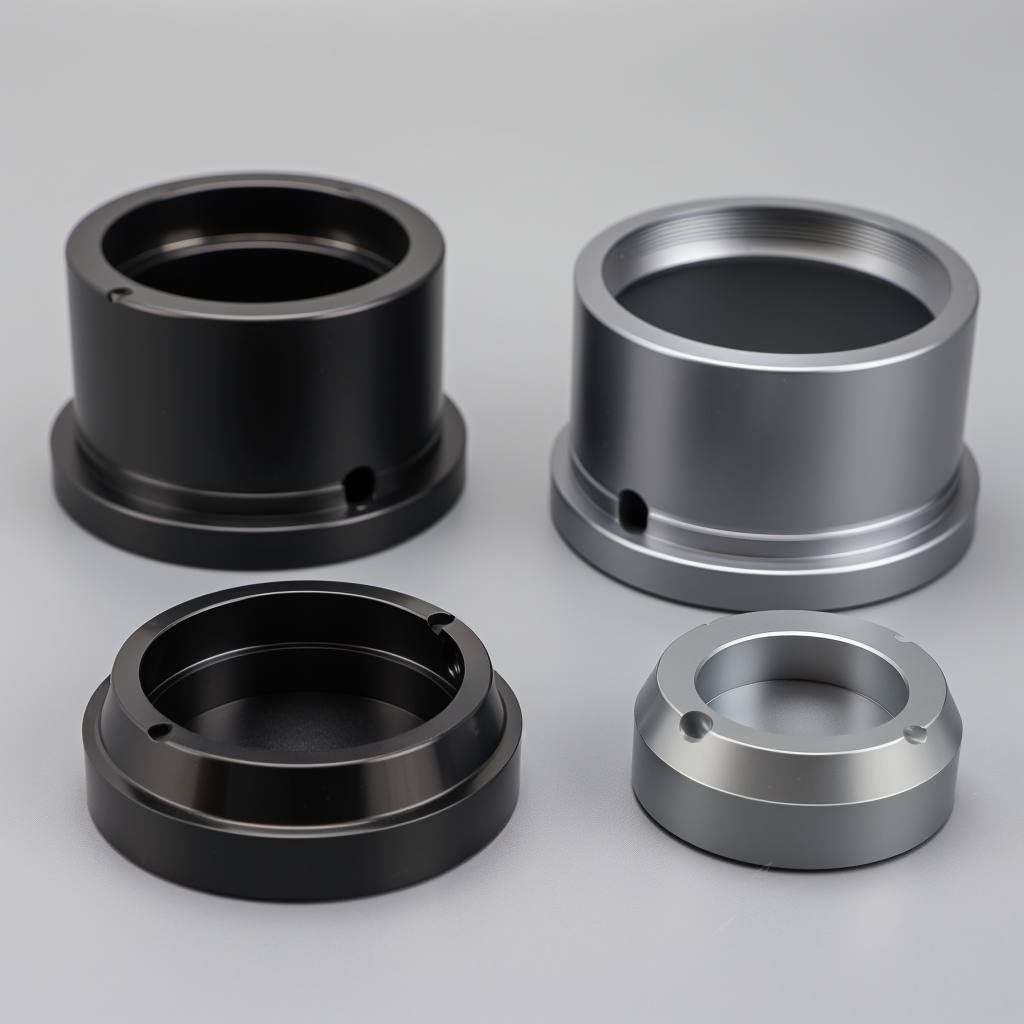

Will Black Oxide Coating Affect Your Part Tolerances and Assembly Fit?

Designing precision CNC parts for aerospace, medical, and audio applications means every micron matters. After decades of machining tight-tolerance components and applying various finishes, we’ve learned that black oxide coating raises immediate concerns about dimensional accuracy and assembly fit. No, black oxide coating will not affect your part tolerances or assembly fit. The coating adds […]

Alodine Coating for CNC Aluminum: Design Guide

Choosing the right surface finish for CNC aluminum parts affects both cost and performance. At Okdor, we help engineers across aerospace, medical, and audio industries make finish decisions that optimize project outcomes. This guide answers the key questions about alodine coating: when to use it, tolerance effects, and application suitability. Alodine coating is a chromate […]

When Should You Choose Black Oxide Over Other Finishes?

Choosing surface finishes for precision CNC parts means balancing cost, performance, and dimensional accuracy. Engineers designing components for aerospace, medical, and audio applications consistently face the same decision: when does black oxide make more sense than anodizing, powder coating, or other finish options? Black oxide works best when you need minimal dimensional impact, moderate corrosion […]