Engineers often face conflicting advice about gear pressure angles, leading to over-specified designs and unnecessary CNC machining complexity. With decades of experience manufacturing precision gears for aerospace, medical, and industrial sectors, proper pressure angle selection can dramatically reduce both production cost and design risk.

Answer Section: Five common gear pressure angle myths persist in design engineering: higher angles don’t always improve strength, different pressure angles cannot be mixed, pressure angle significantly affects noise, it impacts fatigue life, and pressure angle and profile shift are not interchangeable manufacturing solutions.

Uncover gear angle myths, their impact on machining and performance, and when to use non-standard angles without complicating CNC production.

Table of Contents

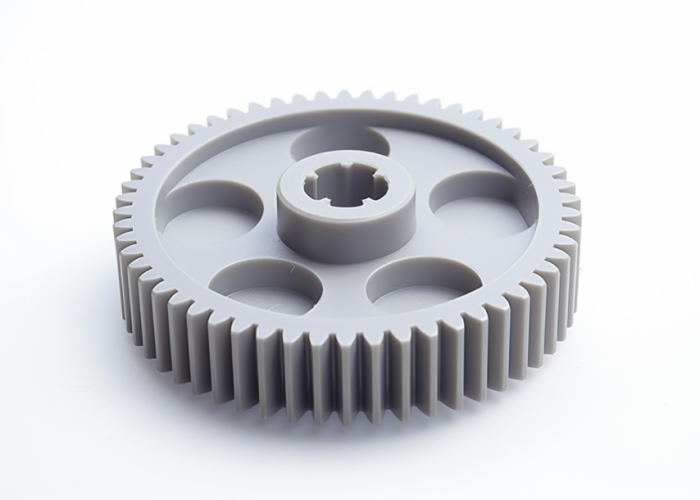

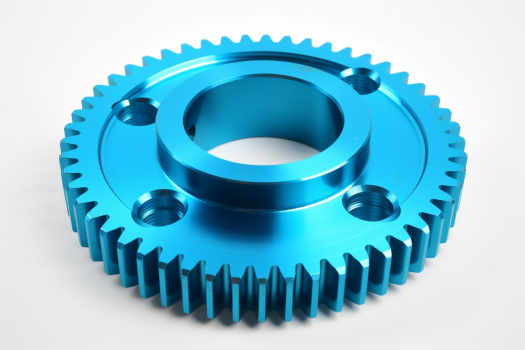

What Are the Key Differences Between Pressure Angles?

Standard 20° pressure angles provide balanced performance for most CNC-machined gears, while 14.5° reduces noise at the cost of load capacity, and 25°+ increases strength but creates higher bearing loads. Each angle directly impacts machining complexity, tooling requirements, and gear system performance.

During precision gear production, we consistently measure distinct performance differences across pressure angle selections:

- 14.5° Low Pressure Angle: Higher contact ratios (1.4-1.6), 15-20% noise reduction, lower load capacity, reduced bearing loads, longer fatigue life

- 20° Standard Pressure Angle: Moderate performance across all parameters, optimal for general-purpose applications, standard CNC tooling compatibility

- 25°+ High Pressure Angle: 20-30% increased load capacity, lower contact ratios, 40% higher bearing loads, increased noise levels, shorter fatigue life

Medical device gears often specify 14.5° for quiet operation in patient-facing equipment, while aerospace applications utilize 25°+ angles for maximum strength-to-weight performance. These specifications directly affect CNC setup complexity—higher pressure angles require more robust workholding due to increased cutting forces during tooth machining.

Design Takeaway: Choose 14.5° for noise-critical applications, 20° for general-purpose designs, and 25°+ only when maximum load capacity justifies increased bearing loads and machining complexity.

Higher Pressure Angles Always Improve Gear Strength

This myth ignores critical trade-offs—while higher pressure angles increase load capacity by 20-30%, they simultaneously create 40% higher bearing loads and increased noise that often negate strength benefits. The assumption that “higher angle equals better performance” leads to over-engineered designs with unnecessary complexity and cost.

During CNC gear manufacturing, we frequently encounter designs specifying 25°+ angles solely for perceived strength advantages. Reality shows multiple performance penalties:

- Increased Bearing Loads: 25°+ angles create 40% higher radial forces, requiring larger bearings and more robust housings

- Higher System Noise: Reduced contact ratios from high pressure angles increase operational noise by 25-35%

- Manufacturing Complexity: Higher cutting forces during CNC machining demand more rigid workholding and slower feed rates

- System Weight Penalty: Larger bearings and housings often eliminate the original strength-to-weight advantage

Audio equipment with 25°+ pressure angle gears generates unacceptable noise levels despite theoretical strength gains. Medical devices requiring quiet operation cannot utilize high pressure angles regardless of load capacity benefits. Even aerospace applications must balance strength needs against bearing load penalties and system complexity.

Design Takeaway: Higher pressure angles improve tooth strength but create system-level penalties in bearing loads, noise, and complexity—specify them only when maximum load capacity functionally justifies these trade-offs, not as automatic “safety margins.”

Myth: Pressure Angle Has No Effect on Gear Noise

This myth completely ignores the direct relationship between pressure angle and contact ratio—the primary factor controlling gear noise levels. Lower pressure angles (14.5°) achieve contact ratios of 1.4-1.6, delivering 15-20% noise reduction compared to 20° angles, while higher angles (25°+) reduce contact ratios and significantly increase operational noise.

Engineers who dismiss pressure angle’s acoustic impact overlook fundamental performance relationships that directly affect system noise:

- Contact Ratio Impact: 14.5° angles provide 1.4-1.6 contact ratios vs. 1.1-1.3 for 25°+ angles

- Load Distribution: Higher contact ratios spread forces across more teeth, reducing individual tooth stress and noise generation

- Torque Smoothness: More teeth in contact create smoother torque transmission with reduced vibration

- Noise Measurement: 25°+ pressure angles typically generate 25-35% higher noise levels than 14.5° configurations

We’ve machined precision gears for audio applications where specifying 14.5° pressure angles was essential for acceptable noise performance in motor drive systems. Medical devices similarly require quiet operation that higher pressure angles cannot deliver. The myth that pressure angle doesn’t affect noise leads to costly redesigns when prototypes fail acoustic testing.

Design Takeaway: Pressure angle selection directly impacts system noise through contact ratio changes—never assume acoustic performance is independent of pressure angle choice when designing noise-sensitive applications.

Pressure Angle Changes Don't Affect Fatigue Life - Debunked

Pressure angle directly influences contact stress distribution and fatigue performance—lower pressure angles (14.5°) extend fatigue life through higher contact ratios, while higher angles (25°+) concentrate stress and reduce component longevity. Maximum contact stress between meshing teeth varies significantly with pressure angle selection, directly impacting gear durability.

Engineers dismissing pressure angle’s fatigue impact ignore fundamental stress mechanics that determine component lifespan:

- Contact Stress Distribution: 14.5° angles distribute loads across larger contact areas, reducing peak stress concentrations

- Fatigue Life Extension: Higher contact ratios from lower pressure angles can extend gear life by 30-50% in cyclic loading applications

- Stress Concentration: 25°+ angles create higher peak contact stresses despite increased load capacity

- Material Utilization: Lower contact stress allows better fatigue performance from the same material and heat treatment

Medical device applications demonstrate this relationship clearly—gears operating continuously for years require 14.5° pressure angles to achieve target service life. Industrial equipment with intermittent high loads may tolerate shorter fatigue life from 25°+ angles when peak strength is critical. This misconception leads to premature failures when designs ignore fatigue implications of pressure angle selection.

Design Takeaway: Consider fatigue life requirements when selecting pressure angles—lower angles extend component life through reduced contact stress, while higher angles sacrifice longevity for peak load capacity.

Can You Mix Gears with Different Pressure Angles?

No—gears in mesh must have identical pressure angles and pitch to operate correctly. Attempting to mesh gears with different pressure angles results in poor contact, excessive wear, and likely failure due to incompatible tooth geometry.

Gear meshing demands precise geometric compatibility that different pressure angles cannot provide:

- Tooth Profile Incompatibility: Different pressure angles create incompatible involute curves that cannot mesh properly

- Contact Pattern Problems: Mismatched angles cause edge contact, point loading, and rapid wear progression

- Manufacturing Impossibility: Standard CNC gear cutting tools cannot create compatible tooth forms for different pressure angles

- Design Rule Violation: This violates fundamental gear design principles taught in all mechanical engineering curricula

We’ve seen costly prototyping failures when engineers attempt to “upgrade” single gears in existing gearboxes with different pressure angles. The replacement gear either won’t mesh properly or creates immediate wear and noise problems. This misconception often arises from confusion between pressure angle and other gear parameters like module or number of teeth, which can sometimes be mixed within limits.

Design Takeaway: All gears in mesh must share identical pressure angles and pitch—never attempt to mix different pressure angles in the same gear train, as this violates fundamental meshing requirements and guarantees poor performance.

Are Pressure Angle and Profile Shift Interchangeable Solutions?

No—pressure angle affects entire gear geometry and requires new cutting tools, while profile shift modifies tooth thickness using standard tooling and is more cost-effective for minor adjustments. Understanding their different roles prevents unnecessary CNC complexity and tooling costs.

These design approaches serve different purposes and cannot substitute for each other:

- Pressure Angle Changes: Require new cutting tools, affect entire load distribution, contact ratio, and bearing loads across the system

- Profile Shift Benefits: Uses standard tooling, adjusts only tooth thickness and root strength, more economical for minor corrections

- Manufacturing Impact: Pressure angle changes demand complete tool setup modifications, while profile shift uses existing hobs with position adjustments

- Performance Effects: Pressure angle affects system-wide characteristics, profile shift primarily influences individual gear strength and center distance

Profile shift often provides a more practical solution for avoiding undercutting in small pinions or adjusting center distances without changing the entire gear system’s noise and load characteristics. Pressure angle modification affects multiple performance parameters simultaneously and should be reserved for fundamental system requirement changes, not minor geometric adjustments.

Design Takeaway: Use profile shift for cost-effective tooth geometry adjustments with standard tooling, and reserve pressure angle changes for fundamental system performance modifications that justify new cutting tools and setup complexity.

Conclusion

Pressure angle selection requires balancing strength, noise, fatigue life, and bearing loads rather than defaulting to higher angles. Choose 14.5° for quiet operation, 20° for general applications, and 25°+ only when maximum load capacity justifies system trade-offs. Contact us to explore gear manufacturing solutions tailored to your pressure angle requirements.

Frequently Asked Questions

Use 20° for general products, 14.5° for noise-sensitive consumer electronics or medical devices, and 25°+ only for high-load industrial applications where you can accommodate larger bearings and accept higher noise levels.

Standard 20° angles use common tooling with no cost premium. Non-standard angles (14.5° or 25°+) require specialized cutting tools, adding 15-25% to gear machining costs and potentially extending lead times.

No. All gears in mesh must share identical pressure angles and pitch. Mixing different angles creates incompatible tooth profiles that cannot mesh properly, leading to immediate failure.

Specify 14.5° only if noise testing shows standard gears exceed your acoustic requirements. Choose 25°+ only when load analysis proves 20° angles insufficient and your housing design can handle 40% higher bearing loads.

Use profile shift for minor adjustments like center distance corrections or avoiding undercutting—it’s more economical and uses standard tooling. Reserve pressure angle changes for fundamental performance requirements affecting the entire system.

Factor in noise requirements, bearing size limitations, housing space, manufacturing cost targets, and assembly tolerances. Higher pressure angles improve strength but require larger bearings and create design complexity throughout your system.