In precision engineering, worm gear performance hinges on material selection. With manufacturing costs rising and efficiency demands increasing, choosing the right materials and coatings can significantly extend gear life and reduce maintenance frequency.

The essential materials for optimal worm gear performance include three specialized gear materials (Phosphor Bronze, Aluminum Bronze, and Tin Bronze) and five worm materials/coatings (Hardened Steel, Carburized Steel, DLC, TiN, and Electroless Nickel Plating), each serving specific wear-reduction purposes.

Ready to dive deeper? Discover how these eight proven materials and coatings can transform your worm gear system’s durability and performance.

Table of Contents

Essential Materials for Worm Gear Systems

In the quest to minimize wear in worm gear systems, eight specific materials and coatings have proven their exceptional value. These include three specialized materials for the worm gear component and five advanced materials and coatings for the worm itself. Understanding these options and their unique wear-reduction properties is crucial for achieving optimal system longevity. Let’s examine how each material contributes to wear reduction, starting with worm gear materials before moving on to worm materials and their protective coatings.

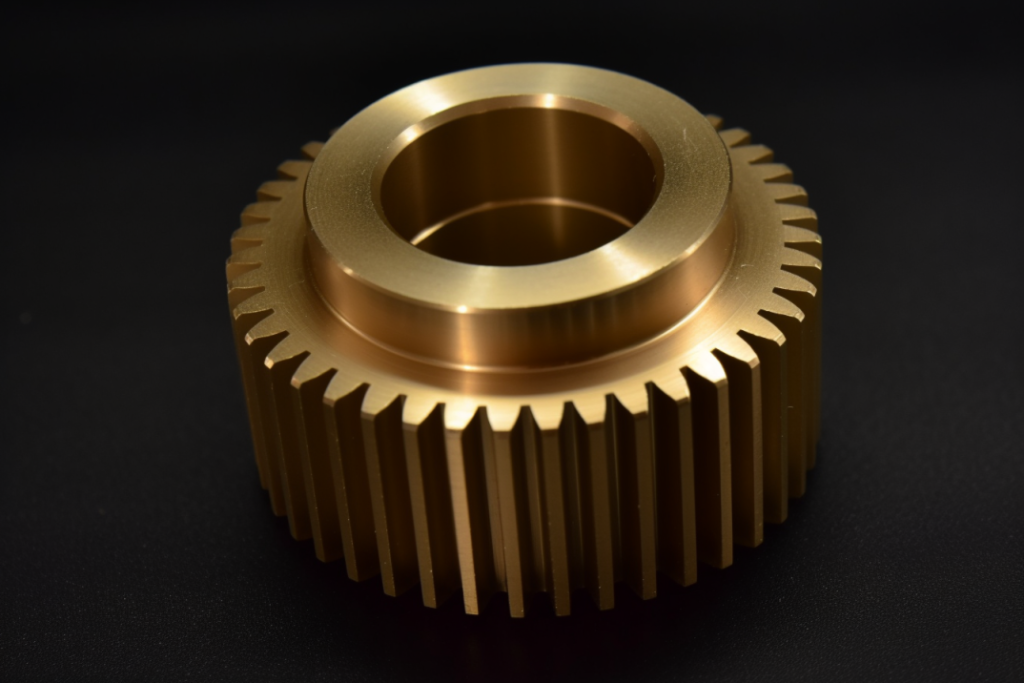

1. Phosphor Bronze (CAC502)

This industry-standard material leads the field in worm gear applications, particularly excelling in high-load environments. At its core, Phosphor Bronze CAC502 combines excellent wear resistance with high load-bearing capacity, making it the go-to choice for demanding industrial applications.

Wear Performance Characteristics

Under normal operating conditions, CAC502 demonstrates exceptional wear reduction properties, achieving wear rates as low as 2-5 micrometers per 1000 hours of operation. The material’s self-lubricating phosphorus content significantly reduces friction, maintaining a coefficient between 0.05-0.10. Even under demanding conditions with surface pressures reaching 200 MPa, CAC502 maintains its structural integrity. During high-speed operations, its resistance to scoring and galling ensures consistent gear performance and longevity.

Operational Capabilities

In industrial applications, CAC502 truly shines through its robust operational capabilities. The material maintains its strength at temperatures up to 280°C while providing natural dampening characteristics that reduce operational noise. Its service life extends 30-40% longer than standard bronze alloys, offering significant value in long-term operations. Most importantly, in critical situations where lubrication might fail, CAC502’s emergency running properties provide an additional safety margin against catastrophic failure.

Industrial Applications

Continuous operation systems benefit particularly from CAC502’s characteristics. The material performs exceptionally well in environments with high loads and speeds, where system reliability is crucial and maintenance opportunities are limited. Industrial conveyor systems and heavy machinery applications frequently utilize CAC502 for its consistent performance and minimal maintenance requirements.

Element Composition (%) Role in Worm Gear Performance

Copper 88.0 – 90.0 Base metal providing ductility and thermal conductivity

Tin 10.0 – 12.0 ★ Increases hardness and wear resistance

Phosphorus 0.3 – 0.8 ★ Key for self-lubricating properties and reducing friction

Lead 0.3 max Improves machinability

Zinc 0.3 max Improves fluidity in casting

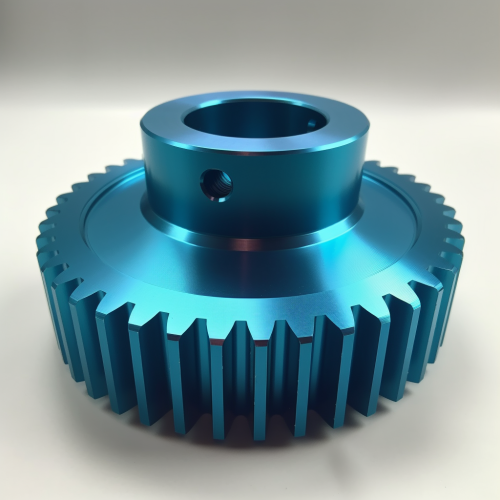

2. Aluminum Bronze

In worm gear materials, Aluminum Bronze stands out for its exceptional combination of light weight and performance characteristics. This versatile material provides an optimal balance between weight reduction and wear resistance, while offering superior thermal properties that make it invaluable in high-speed applications.

Operational Capabilities

In practical operations, Aluminum Bronze delivers substantial efficiency gains through its unique properties. The material achieves a 15-20% weight reduction compared to traditional bronze alloys while maintaining excellent resistance to thermal fatigue. Its corrosion resistance proves exceptional, enhanced by a self-healing oxide layer that provides continuous protection in aggressive environments, ensuring sustained performance even in challenging conditions.

Industrial Applications

High-speed precision machinery particularly benefits from Aluminum Bronze’s characteristics. The material excels in applications where weight reduction is critical and heat generation is a concern. Its superior performance in corrosive environments and ability to handle frequent start-stop cycles make it ideal for precision instruments and automated manufacturing equipment where consistent performance is essential.

Element Composition (%) Role in Worm Gear Performance

Copper 78.0 – 82.0 Base metal providing strength and conductivity

Aluminum 8.5 – 9.5 ★ Provides wear resistance and reduces weight

Iron 3.0 – 5.0 ★ Increases hardness and strength

Nickel 4.0 – 5.0 ★ Enhances corrosion resistance and strength

Manganese 0.8 – 1.5 Improves deoxidation during manufacturing

3. Tin Bronze (C91700)

The development of Tin Bronze C91700 represents a significant advancement in heavy-duty worm gear applications. This material excels in situations that demand exceptional wear resistance combined with high structural strength, setting new standards for performance in demanding environments.

Wear Performance Characteristics

C91700’s wear performance sets new benchmarks in material durability. In optimal conditions, it achieves remarkably low wear rates of less than 1 micrometer per 1000 hours of operation. The material maintains its stability under intense pressure, handling surface pressures up to 250 MPa while keeping friction coefficients between 0.04-0.08, even as loads vary. This consistent performance under challenging conditions has established C91700 as a premier choice for high-stress applications.

Operational Capabilities

The operational characteristics of C91700 further distinguish it in the field of high-performance materials. With fatigue strength exceeding standard bronze alloys by 25%, it delivers exceptional performance even in poorly lubricated conditions. The material’s resistance to shock loading and minimal deformation under high loads provides a significant advantage in demanding industrial environments, while its extended service life reduces maintenance requirements and system downtime.

Industrial Applications

Heavy industrial machinery and continuous operation systems benefit most from C91700’s robust characteristics. The material proves invaluable in applications requiring maximum load-bearing capacity and resistance to shock loading. Its ability to perform reliably in less-than-ideal lubrication conditions, combined with its long service life, makes it particularly suitable for heavy machinery and industrial gearboxes where system reliability is paramount.

Element Composition (%) Role in Worm Gear Performance

Copper 57.0 – 61.0 Base metal providing ductility and conductivity

Tin 37.0 – 41.0 ★ High percentage for maximum wear resistance and strength

Lead 1.5 – 2.5 ★ Enhances self-lubricating properties

Zinc 0.8 max Improves castability

Iron 0.2 max Grain refinement

Five Critical Worm Materials and Coatings

Modern worm design relies heavily on the proper selection of materials and surface treatments to achieve optimal performance. Among various options, five specific materials and coatings have proven particularly effective for worm components. Each brings unique properties that enhance wear resistance and operational efficiency.

1. Hardened Steel

In worm gear systems, wear reduction begins with proper material selection for the worm component. Hardened steel has established itself as a critical material choice due to its exceptional ability to withstand wear while maintaining dimensional stability under load. When properly heat-treated, hardened steel creates an ideal surface hardness that minimizes wear during the continuous sliding contact characteristic of worm gear operation.

When selecting hardened steel for worm applications, several specific grades have emerged as industry standards, each offering distinct advantages for wear reduction. The choice between these grades often depends on the specific requirements of the application, particularly regarding surface hardness, core properties, and overall wear resistance:

Steel Grade Surface Hardness (HRC) Key Properties Best For Wear Reduction In

AISI 4340 58-62 • Chromium-molybdenum composition • Medium-duty worm drives

• Good balance of surface hardness and core toughness • Applications with moderate shock loads

• Excellent wear resistance • General industrial gearboxes

AISI 4340 58-62 • Enhanced nickel content • Heavy-duty worm gear systems

• Superior wear resistance • High-load applications

• Better fatigue strength • Continuous operation equipment

AISI 8620 60-62 (case depth) • Case-hardened structure • Variable load systems

• Ductile core with hard surface • Impact-prone applications

• Excellent shock resistance • Precision worm gear drives

These hardened steel grades, properly paired with bronze worm gears, deliver exceptional wear resistance in gear systems. Their combination of high surface hardness and dimensional stability enables wear rates as low as 0.1-0.3 micrometers per 1000 hours, while withstanding compressive loads up to 2000 MPa. This performance profile makes them particularly effective for industrial gearboxes and heavy machinery drives where precision and longevity are paramount.

2. Carburized and Ground Steel

Carburization represents an advanced surface hardening process that is particularly effective in minimizing worm gear wear. Through the process of carbon diffusion and subsequent heat treatment, carburized and ground steel achieves exceptional surface properties while maintaining a tough core – a combination that proves invaluable in worm gear applications where both wear resistance and strength are crucial.

Several steel grades are particularly well-suited for carburization in worm applications, each offering specific advantages for wear reduction:

Steel Grade Case Depth (mm) Key Properties Best For Wear Reduction In

AISI 8620 0.8-1.5 • Most widely used carburizing grade • Standard worm drives

• Excellent case hardness (60-62 HRC) • General industrial applications

• Good core toughness • Moderate load conditions

AISI 4320 1.0-2.0 • Higher alloy content for deeper case • Heavy-duty applications

• Superior core strength • High-load worm drives

• Better wear resistance • Continuous operation systems

AISI 9310 1.2-2.5 • Premium carburizing grade • Precision worm gear systems

• Maximum case hardness (62-64 HRC) • Critical applications

• Outstanding fatigue resistance • High-speed operations

The carburizing process creates a hardened surface layer that excels in wear reduction, achieving surface hardness up to 60-64 HRC while maintaining core hardness around 35-45 HRC. This dual-property structure, combined with precision grinding, results in optimal wear characteristics for worm applications. Common uses include heavy machinery, precision equipment, and high-load gear systems where surface durability is essential for extended service life.

Advanced Coatings and Surface Treatments

In worm gear systems, surface engineering plays a crucial role in extending component life and enhancing performance. Advanced coatings and surface treatments represent the cutting edge of wear-reduction technology, offering properties that significantly exceed those of base materials alone. These surface modifications create optimal tribological conditions, reducing friction and wear while improving load-bearing capacity in worm gear applications.

Coatings for Worms

The worm component in a gear system experiences continuous sliding contact, making it particularly susceptible to wear. Modern coating technologies have revolutionized worm surface protection, offering unprecedented levels of hardness, lubricity, and wear resistance. Three specific coating types have emerged as leading solutions, each bringing unique advantages to wear reduction in worm applications.

3. Diamond-Like Carbon (DLC)

In the pursuit of superior wear reduction for worm components, Diamond-Like Carbon (DLC) coating has emerged as a breakthrough surface treatment technology. This advanced coating combines diamond’s exceptional hardness with graphite’s natural lubricity, creating an ideal surface for worm gear applications where minimizing friction and wear is paramount.

Several DLC coating variants have been developed, each optimized for specific wear reduction requirements:

DLC Type Hardness (GPa) Key Properties Best For Wear Reduction In

a-C:H (Hydrogenated) 20-25 • Lowest friction coefficient (0.02-0.07) • High-speed worm drives

• Good chemical inertness • Oil-lubricated systems

• Excellent adhesion to steel • Precision gear applications

ta-C (Tetrahedral) 40-60 • Maximum hardness • Heavy-load applications

• Superior wear resistance • Harsh operating conditions

• Higher temperature stability • Extended service life requirements

a-C (Non-hydrogenated) 30-40 • Balanced hardness and toughness • General industrial worm gears

• Good thermal conductivity • Mixed lubrication conditions

• Smooth surface finish • Medium-duty applications

DLC coatings achieve exceptional wear reduction through their unique combination of ultra-high hardness (up to 60 GPa) and extremely low friction coefficients (as low as 0.02). When applied to hardened steel worms, these coatings can extend service life by 2-3 times compared to uncoated components, particularly in demanding applications where conventional lubrication alone is insufficient. The coating’s effectiveness in reducing friction and wear makes it especially valuable in high-speed precision machinery and critical industrial systems where reliability is essential.

4. Titanium Nitride (TiN)

Titanium Nitride coating represents a proven solution in worm gear wear reduction, combining excellent hardness with superior adhesion properties. This golden-colored ceramic coating has become a standard in high-performance gear applications due to its ability to significantly reduce friction and extend component life even under demanding conditions.

Various TiN coating processes offer different performance characteristics for wear reduction:

Process Type Coating Thickness (μm) Key Properties Best For Wear Reduction In

PVD TiN 2-4 • Sharp edge retention • Precision worm drives

• Excellent surface finish • High-speed applications

• High dimensional accuracy • Temperature-sensitive components

CVD TiN 4-8 • Maximum adhesion strength • Heavy-load worm gears

• Better wear resistance • Continuous operation systems

• Higher temperature tolerance • Harsh environment applications

Arc TiN 3-6 • Enhanced hardness (2300-2500 HV) • Mixed load conditions

• Superior impact resistance • Variable speed operations

• Good chemical stability • Industrial gear systems

TiN coatings deliver exceptional wear reduction through their high surface hardness (2000-2500 HV) and low friction coefficient (0.4-0.5). Applied to properly prepared worm surfaces, TiN can extend component life by up to 300% while improving system efficiency through reduced friction. These characteristics make it particularly effective in industrial gearboxes and automated machinery where consistent performance and reduced maintenance are essential.

5. Electroless Nickel Plating

Electroless Nickel Plating offers a unique approach to worm gear wear reduction, providing uniform coating coverage regardless of component geometry. This autocatalytic process deposits a nickel-phosphorus alloy that combines excellent wear resistance with superior corrosion protection, making it particularly valuable in challenging operating environments.

Different phosphorus contents yield varying performance characteristics:

Phosphorus Content Hardness (HV) Key Properties Best For Wear Reduction In

High (10-13%) 500-600 • Maximum corrosion resistance • Corrosive environments

• Good lubricity • Moderate load applications

• Amorphous structure • Chemical processing equipment

Medium (6-9%) 550-650 • Balanced properties • General industrial use

• Better wear resistance • Standard worm drives

• Good ductility • Versatile applications

Low (2-5%) 600-700 • Maximum hardness • High wear conditions

• Best wear resistance • Heavy-duty systems

• Crystalline structure • Abrasive environments

When heat-treated, electroless nickel coatings can achieve hardness values up to 1000 HV, providing exceptional wear resistance. The coating’s uniform thickness and excellent adhesion ensure consistent performance across the entire worm surface, while its inherent lubricity helps maintain low friction coefficients (0.4-0.6). These properties make it particularly suitable for worm gears operating in corrosive environments or where consistent, long-term wear protection is required.

Specialized Materials for Worm Wheels

In the ongoing effort to reduce wear in worm gear systems, specialized materials for worm wheels have become increasingly sophisticated. While bronze alloys serve as traditional choices, advanced self-lubricating materials have emerged as innovative solutions, offering unique advantages in wear reduction and system longevity. These materials combine the structural integrity needed for gear operation with built-in lubrication properties.

Self-lubricating Materials

Modern self-lubricating materials represent a significant advancement in worm wheel technology, incorporating solid lubricants directly into the material matrix. This innovative approach provides continuous lubrication during operation, substantially reducing wear even under challenging conditions.

Various self-lubricating composites offer specific performance benefits:

Material Type Composition Key Properties Best For Wear Reduction In

Bronze-PTFE Composite Bronze matrix with 15-20% PTFE • Natural lubricity (coefficient 0.04-0.08) • Light to medium duty applications

• Excellent wear resistance • Clean environment operations

• Low maintenance requirements • Limited lubrication access

Graphite-Metal Matrix Copper/bronze base with 5-10% graphite • High thermal conductivity • High-speed applications

• Good emergency running • Poor lubrication conditions

• Stable friction properties • Heat-sensitive operations

Metal-Polymer Composite Steel/bronze base with polymer filling • High load capacity • Heavy-duty systems

• Superior impact resistance • Shock load conditions

• Low noise operation • Noise-sensitive applications

These specialized materials achieve wear reduction through a unique combination of mechanical strength and continuous lubrication. The embedded solid lubricants create a self-replenishing lubricating film during operation, maintaining wear rates as low as 0.3-0.5 micrometers per 1000 hours. This makes them particularly valuable in applications where traditional lubrication is difficult to maintain or where system reliability is paramount, such as automated machinery and remote operation equipment.

Lubricants

In worm gear wear reduction, proper lubrication plays a vital role beyond basic friction reduction. Advanced lubricant formulations actively protect gear surfaces, manage heat generation, and create optimal operating conditions for extended system life. Understanding the characteristics and applications of different lubricant types is crucial for maximizing wear reduction in worm gear systems.

6. Polyalphaolefin (PAO) Gear Oils

Polyalphaolefin oils represent the premium choice in synthetic gear lubrication, offering superior wear protection across a wide temperature range. These advanced synthetic oils combine excellent thermal stability with outstanding wear-reduction properties.

For standard industrial applications, ISO VG 150-220 grades provide excellent thermal stability and oxidation resistance, making them ideal for moderate load applications and operations across wide temperature ranges. In heavy-duty applications, higher viscosity grades (ISO VG 320-460) deliver enhanced film strength and maximum wear protection, particularly valuable in high-load conditions and elevated temperatures.

The most demanding applications benefit from ultra-high viscosity grades (ISO VG 680-1000), which offer maximum viscosity stability and extreme pressure protection for slow speed, high-torque operations.

7. Synthetic Gear Oils

Modern synthetic gear oils deliver enhanced performance through advanced molecular engineering. Polyglycol-based synthetics typically achieve 15-20% efficiency gains through superior load capacity and thermal conductivity, making them excellent choices for high-speed applications and temperature-critical systems. Ester-based synthetics, with their natural detergency and excellent metal affinity, provide 10-15% efficiency improvements and excel in high-temperature operations where clean-running is essential. Synthetic blends offer a cost-effective middle ground, delivering 5-10% efficiency gains while maintaining good compatibility with various system components.

Compounded Oils

These specially formulated lubricants incorporate advanced additive technologies to enhance wear protection in worm gear applications. EP (Extreme Pressure) compounded oils, containing 3-5% specialized additives, excel in high-load applications and boundary lubrication conditions. Fatty acid modified oils, with 5-10% fatty acid content, provide improved film strength and surface adhesion, particularly beneficial for bronze/steel gear combinations. Multi-functional compounded oils blend various additives to deliver comprehensive protection across diverse operating conditions.

The effectiveness of these lubricants in reducing wear stems from their ability to maintain stable lubricating films under challenging conditions. Proper selection based on operating parameters and system requirements can significantly extend gear life while improving overall system efficiency. Key considerations include operating temperature range, load conditions, speed, and environmental factors.

Conclusion

Effective wear reduction in worm gear systems depends on the strategic selection of materials and coatings. From hardened steels and specialized bronze alloys for base components to advanced DLC and TiN coatings, each material choice plays a crucial role. When combined with appropriate self-lubricating materials and modern lubricant technologies, these eight essential materials and coatings create a comprehensive approach to minimizing wear. Understanding and implementing these options enables engineers to achieve optimal performance and extended service life in worm gear applications.

Frequently Asked Questions

Coatings like DLC and TiN create an extremely hard, low-friction surface layer that reduces wear, prevents material loss, and improves lubrication effectiveness, potentially doubling or tripling component life.

Lubricants create a protective film between gear surfaces, reduce friction, dissipate heat, and prevent metal-to-metal contact. Synthetic oils can improve efficiency by up to 15% compared to conventional oils.

Yes, advanced surface finishing techniques like isotropic superfinishing can significantly improve load capacity, reduce friction, and enhance overall system efficiency by creating optimal surface characteristics.

Self-lubricating materials reduce maintenance requirements, provide consistent lubrication, and can operate in environments where traditional lubrication might be problematic or insufficient.

Proper material selection, combined with precision manufacturing and appropriate coatings, helps maintain tight tolerances and reduces wear, which directly minimizes backlash development over time.

The optimal combination is typically a Phosphor Bronze (CAC502) worm gear paired with a hardened steel worm, both treated with appropriate surface coatings like DLC or TiN for maximum wear resistance and minimal friction.