Hey, welcome to the cool world of CNC turning and lathes! Seriously, these machines are the rockstars of manufacturing. They’re why your car runs smoothly and why that custom metal piece in your living room looks so sleek.

So, why should you care? If you’re into making stuff, these machines are your best friends. They take chunks of metal and turn them into anything you can imagine. No CNC, no modern world—simple as that.

we’ll dive into CNC turning, why it’s the MVP of machining, and what kind of cool stuff you can make with it. Ready? Let’s go!

Understanding CNC Turning

Basic of CNC Turning

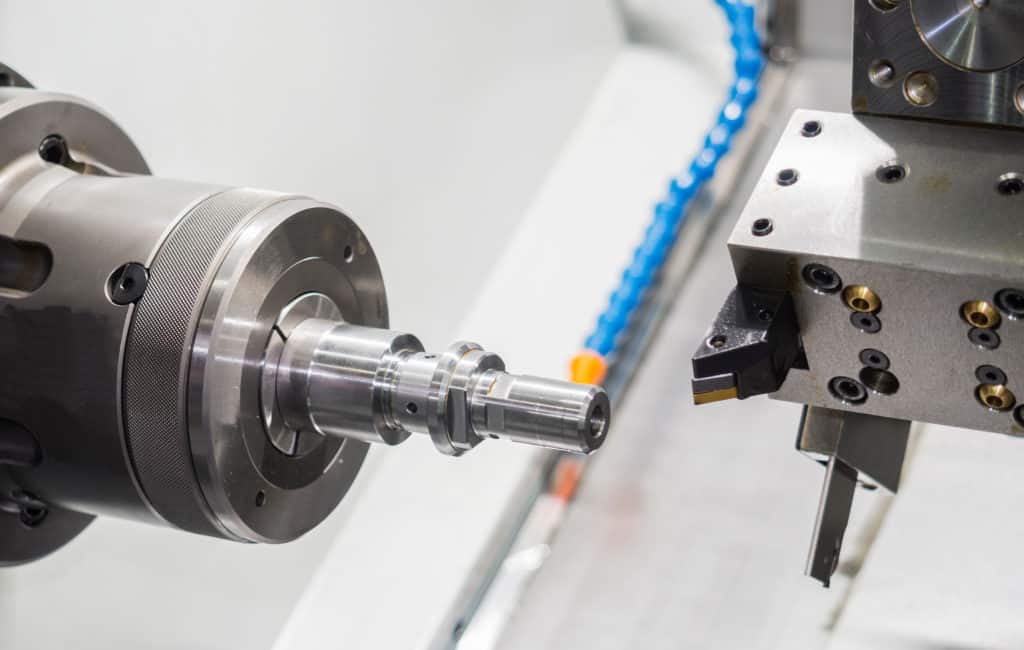

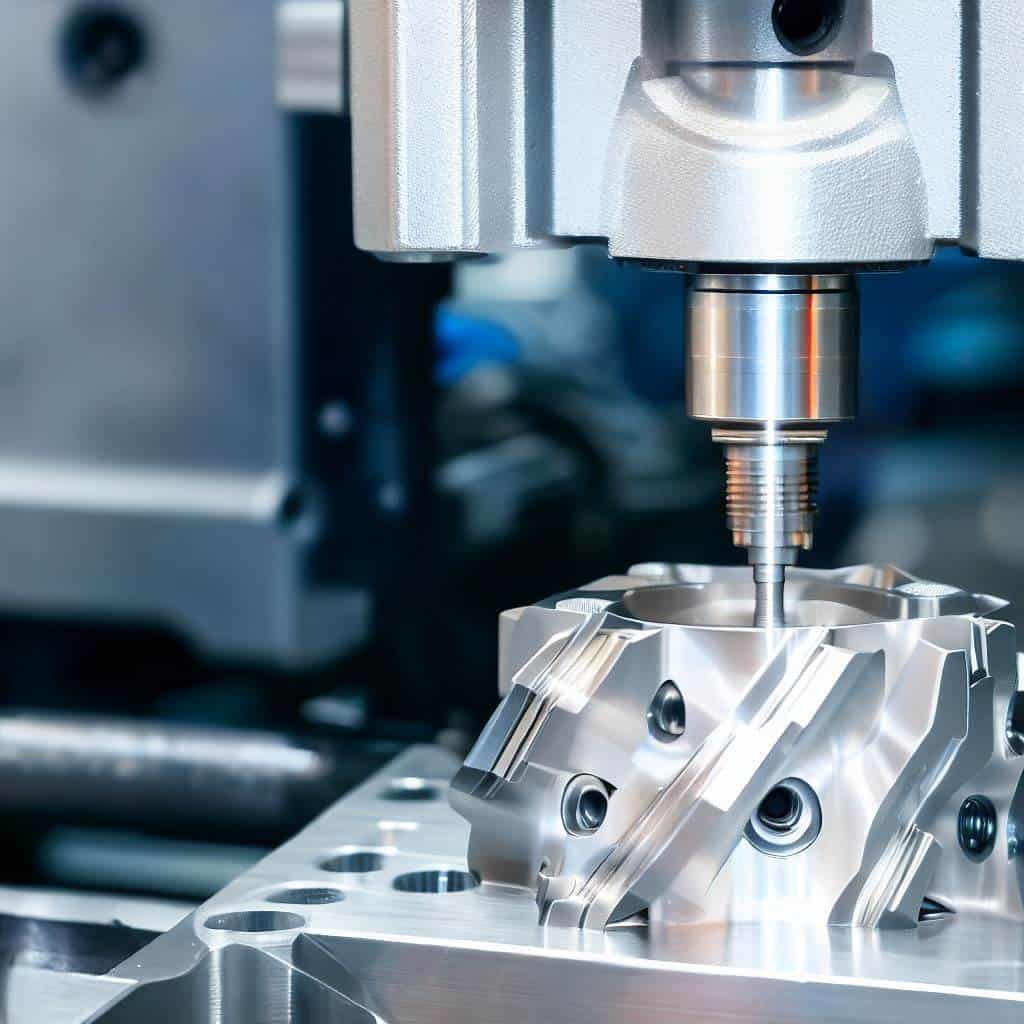

So, what’s CNC turning? Imagine you’ve got a piece of metal—anything, stainless steel, aluminum—and want to shape it. You pop it into this machine, and it spins while another part shaves or drills into it. It’s like sculpting but way more high-tech.

Here’s how it goes down: you’ve got your metal, right? You stick it into this thing called a chuck. It’s like the machine’s hand; it holds the metal tight. Then, as it spins, different tools come in to do their thing—drilling, cutting, you name it.

CNC Turning in Machining Operations

So why is this a big deal? Because CNC turning is like the Swiss Army knife of machining. It can do so much! Do you want a perfectly round part? Done. Need some complex shapes? No problem. It’s super versatile and crazy efficient.

If you’re not into the whole DIY thing, no worries. Some folks specialize in CNC turning. When picking one, check out how fast they can get stuff done, what kind of machines they’re using, and if their control panel looks like something from this century.

Understanding CNC Lathe Machines

What's a CNC Lathe Machine?

So, you’ve heard of CNC turning, but what about CNC lathe machines? They’re like the older, cooler sibling of turning centers. These machines spin your raw material around while a cutting tool shapes it into whatever you need—auto parts, metal pieces, you name it.

Types of CNC Lathes

Alright, let’s talk types. You’ve got your basic CNC lathe machines, and then you’ve got CNC turning centers. What’s the difference? Turning centers are like the Swiss Army knives of lathes; they’ve got more bells and whistles, like live tooling and multiple spindles.

The Guts of the Machine

Let’s break down what’s inside these bad boys:

- CNC Control Panel: Think of this as the brain. It’s where you input all the g code and other commands.

- Lathe Bed: This is the machine’s backbone. It holds everything in place.

- Tool Turret: This is your tool library. Drills, cutters, you name it.

- Main Spindle: This is what spins your workpiece.

- Tailstock Quill: Need to hold something in place? That’s what this is for.

The CNC Machining Process

CNC Turning Process

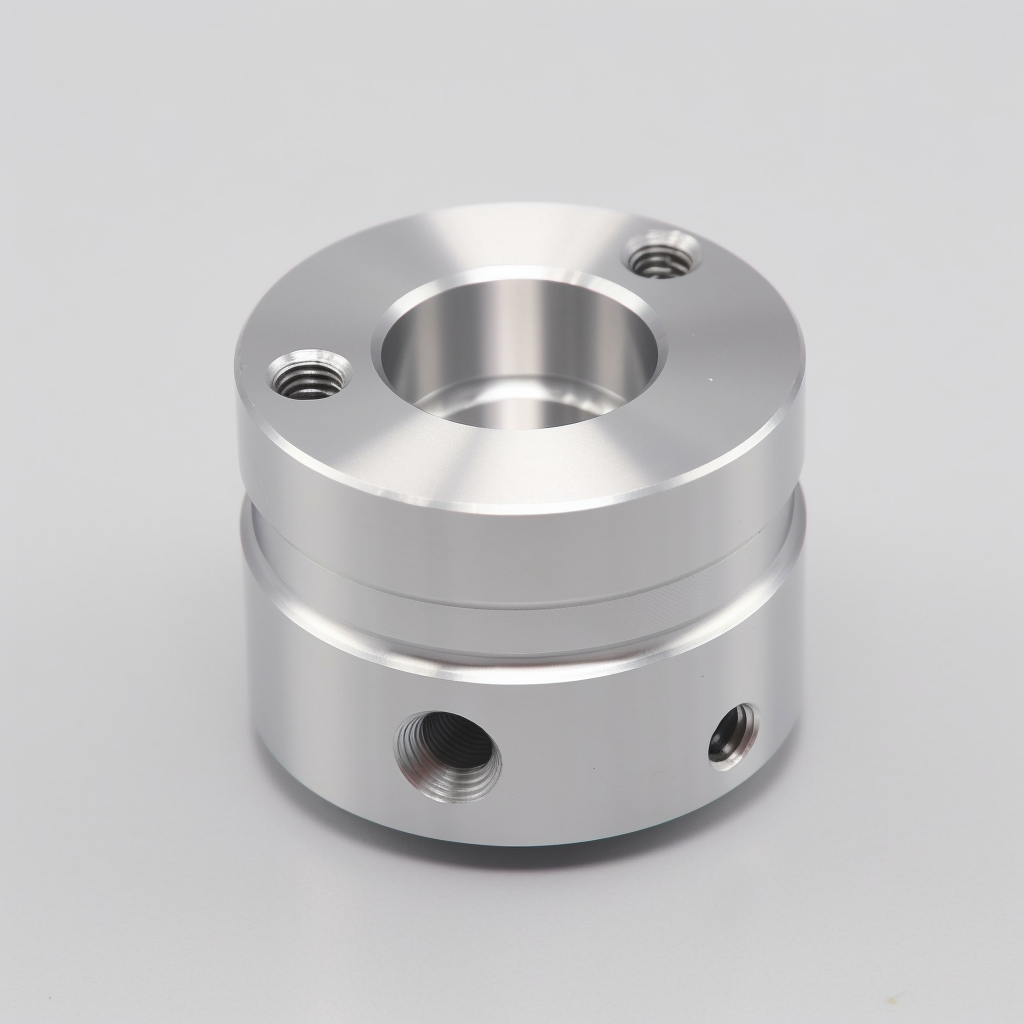

So, you’ve got this chunk of material. It could be metal, could be something else. The machining process is all about turning that chunk into a finished product. We discuss high precision, exact specifications, and a killer surface finish.

Where CNC Lathe Services Fit In

Now, where do CNC lathe services come into play? They’re a key part of the broader CNC machining landscape. Whether you’re into rapid prototyping or mass-producing auto parts, these services can do it all—and fast. Keep an eye on those lead times!

The Role of CNC Control

Last but not least, let’s talk about CNC control. This is where you make the magic happen. You input the commands, and the machine does the rest. Whether removing material, drilling axial and radial holes, or creating complex geometries, CNC control is your best friend.

Tools and Materials

Cutting Tool Selection

So, you’re ready to start CNC turning, but hold up—what about the cutting tools? The tool turret’s got a bunch of options, from drills to cutters. Your choice here really depends on what you’re making. You’ll need specific tools if you’re going for sharp edges or cylindrical features.

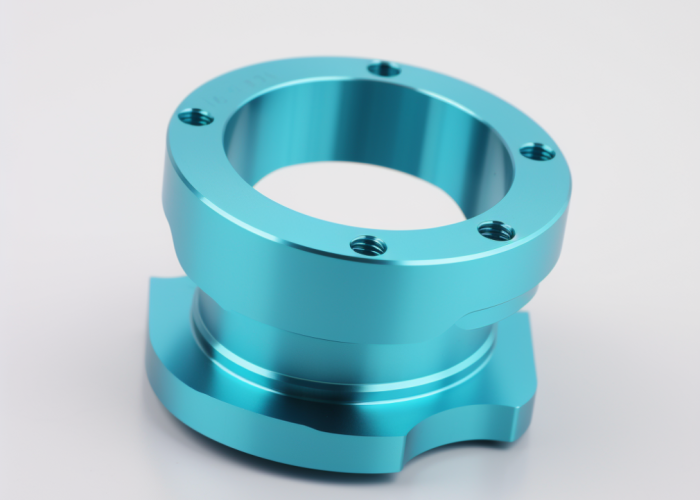

Common Materials

Now, what are you cutting into? Stainless steel is a go-to for a lot of CNC turning parts. It’s durable and looks good. You’ve got other raw material options, like aluminum or some plastics.

Tool selection isn’t just eeny, meany, miny, moe. You’ve got to think about the machining process, the material you’re using, and what kind of finish you want. So, take your time and choose wisely.

Technical Specifications

Maximum Part Length and Diameter

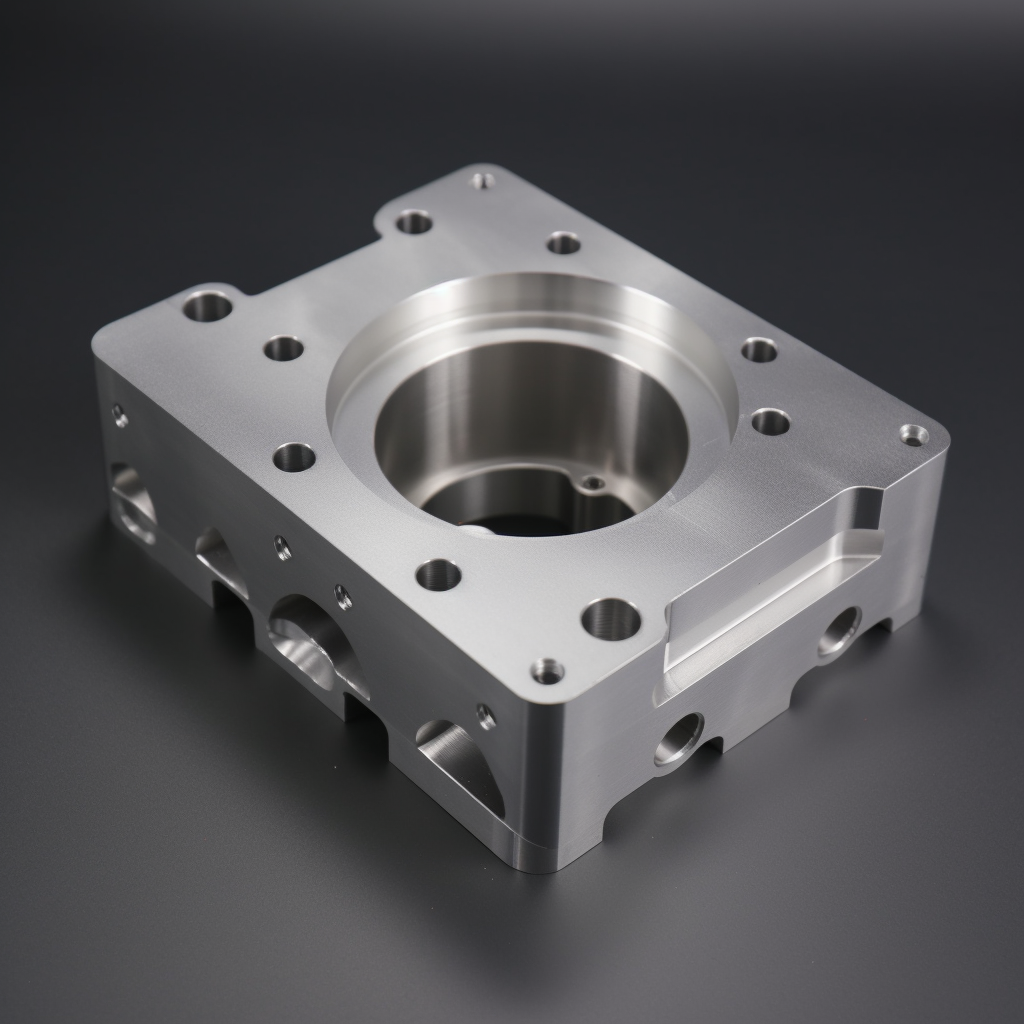

Alright, let’s talk size. Every CNC lathe machine has its limits. You’ve got to know the maximum part length and diameter your machine can handle. Trust me, the last thing you want is to realize your workpiece is too big halfway through.

Axial and Radial

You can drill all kinds of holes with CNC turning—axial, radial; you name it. Ensure you have the right tools in your tool turret for the job.

You want your finished product to look good. Pay attention to the surface finish. You can end up with visible tool marks if you’re not careful. Sometimes that’s the look you’re going for!

Last but not least, let’s talk precision. CNC turning is all about getting those exact specifications. Whether you’re in it for production parts or custom jobs, high precision is the name of the game.

Advanced Features and Operations

Live Tooling Lathe

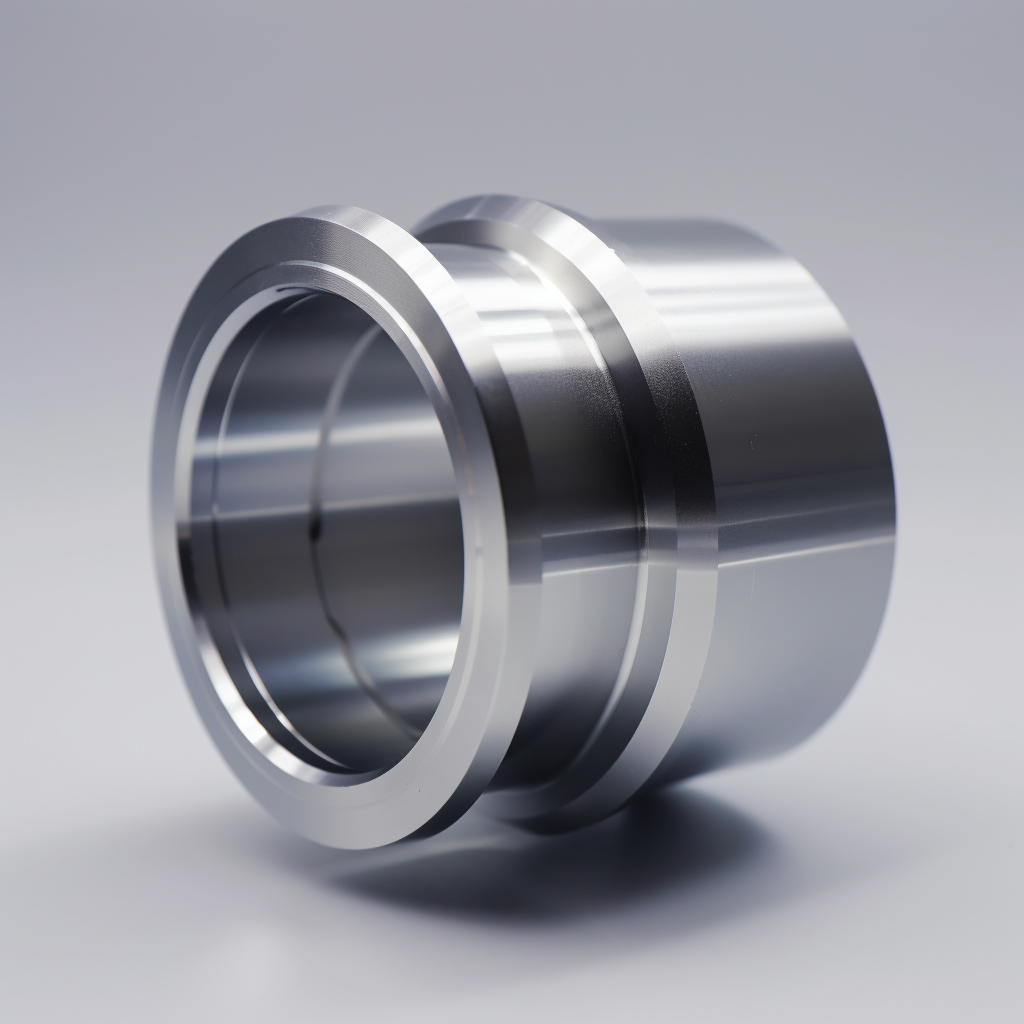

So, you’ve mastered the basics of the CNC turning process, but are you ready for the live tooling lathe? This is a CNC turning center that allows for more complex operations. You can drill, cut, and mill while the main spindle rotates your workpiece.

Taper Turning and Cylindrical Features

Taper turning is where you can show off. You can create tapered shapes with maximum part diameter precision. And if you want to create cylindrical features parts, your CNC lathe bed and tool turret have you covered.

Single Point Threading and Radial Holes

Need to add some threads? Single-point threading is your go-to. And if you’re looking to drill radial holes, just set up your CNC machine and let it do its thing. The rotating chuck will make sure everything lines up perfectly.

Complex Geometries and Finishing Process

Complex geometries aren’t just possible; they’re a piece of cake with the right CNC lathe machine parts and various tools. And when it comes to finishing, you can achieve the desired shape and surface finish, removing material where needed.

Set Up Time and Lead Times

Before touching that control panel, remember that setting up your CNC machines takes time. And if you’re using a CNC turning service, check those lead times. You don’t want to be left hanging.

Whether you’re into rapid prototyping or churning out production parts, CNC turning works for both. You can go from prototype to machined, turned parts in no time.

Lastly, let’s talk about the control panel and foot switch. These are your main interfaces with the machine. Foot pedals help you control various aspects like speed, making it easier to achieve high precision.

How to Choose a CNC Turning Service

What to Look For?

Alright, so you’re thinking of outsourcing your CNC machining, huh?

Cool, but don’t just jump at the cheapest option. Ensure the CNC turning service has the right lathe machines for your gig. Can they handle the nitty-gritty of your machining operations?

Can they work with stainless steel or whip up some complex cylindrical parts? These are the questions, my friend.

Speed and Precision

Look, we all know time’s a ticking clock. You want a quick CNC turning center that doesn’t cut corners—literally. High precision is a game-changer, especially when crafting specialized metal parts. Ask them about their maximum swing and if they’re rocking those four jaw chucks for that extra oomph in precision.

Conclusion

So here’s the deal: CNC turning and lathes are like the unsung heroes of the machining world. Whether spinning a rotating workpiece or shaving off material, these bad boys are your go-to. From the chuck that grips your stuff to the tailstock that keeps everything steady, each part’s got its role to play.

Frequently Asked Questions

CNC turning is a manufacturing process ideal for creating cylindrical shapes or symmetrical parts near their axis, such as chess pawns, bolts, rivets, ball bearings, and washers. This process is particularly suited for rapid prototyping and low-volume production. It allows for taper turning, knurling, threading, and parting. CNC turning can also create undercuts or relief grooves easily.

The tool used for turning on CNC is typically a lathe. The lathe holds a cutting tool against a rotating metal rod or a rigid piece of material, generally cylindrically shaped, to remove material and create final parts. The cutting tool can move along one, two, or three axes of motion, allowing for facing, parting, and grooving operations.

The typical rate of a 3-axis CNC milling machine, excluding the operator’s salary, is $40 per hour. At $35 per hour, CNC turning is usually more affordable. An hourly rate of $75 to $120 is typical for multi-axis CNC machining.

CNC cutting costs usually include the hourly rate of the CNC machine, which can range from $35 to $120 or higher, depending on the complexity and type of machine used.

CNC services are expensive due to several factors. The machinery itself is costly, requiring a significant initial investment. The process demands high precision and specialized cutting tools, which are also expensive. The raw materials used often have stringent specifications, adding to the cost. Additionally, the operation requires skilled labor and can be labor-intensive, increasing expenses.

The six major parts of a lathe machine are:

1. Bed: The main body of the machine where all the main components are bolted.

2. Headstock: Holds gear chains, spindles, and driving pulleys and is driven by an electric motor.

3. Spindle: Holds and rotates the chuck, made from quality alloy steel.

4. Carriage: Holds and moves the tool post along the bed.

5. Tailstock: Supports the loose end of the workpiece or job while machining.

6. Tool Post: Holds the tools at the correct position with rigidity.

Turning involves using a lathe to remove material from a workpiece. On the other hand, CNC turning is a more advanced form of turning that uses computer numerical control (CNC) to automate the process, allowing for greater precision, complexity, and speed.

A CNC lathe machining process involves spinning a material around a central spindle while a fixed cutting tool removes material to shape the workpiece. The movement follows coded instructions fed into a computer. The machine operates on at least two axes, allowing cutting, sanding, and drilling operations. CNC lathes can perform internal and external operations, shaping the components inside and outside.