Achieving superior sheet metal surface quality without costly secondary operations remains a persistent challenge for product developers. Through decades of precision fabrication for aerospace, medical, and industrial applications, Okdor has identified critical decisions during design and material selection that dramatically reduce both cost and lead time.

Improve sheet metal surface quality without extra steps by selecting pre-finished materials like 2B stainless steel (Ra 0.1-0.3 μm), maintaining uniform thickness tolerances (±0.1mm/100mm), and specifying nitrogen-assisted laser cutting. This approach eliminates up to 60% of post-processing requirements.

Explore materials, design tips, and spec strategies for top-tier surface finishes—plus real data on Ra values and cost-saving fabrication results.

Table of Contents

What Materials Give Better Surface Finish Out of the Box?

2B stainless steel (Ra 0.1-0.3 μm) and pre-anodized aluminum (5-25 μm oxide layers) provide superior surface finish directly from the mill, eliminating secondary operations while maintaining consistent appearance through typical fabrication processes.

- 2B stainless steel – Ra 0.1-0.3 μm roughness with scratch resistance and cleanability, ideal for medical devices and food equipment

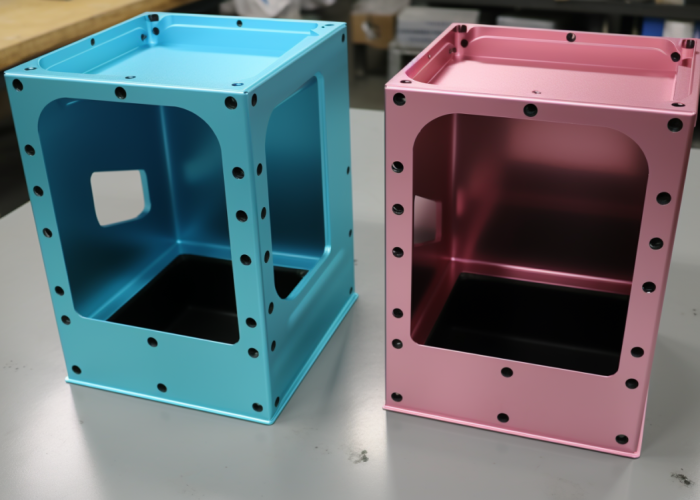

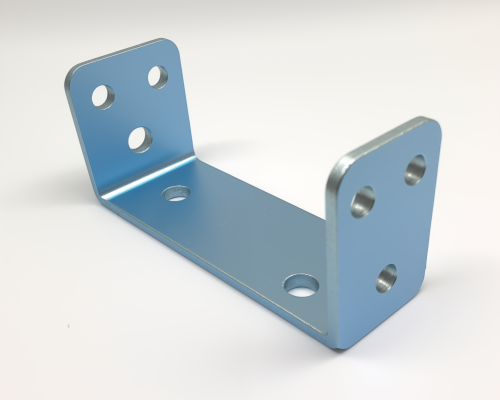

- Pre-anodized aluminum – Ra 0.2-0.4 μm with lightweight construction and color consistency, perfect for electronics enclosures and chassis

In our fabrication experience, 2B stainless steel maintains its Ra 0.1-0.3 μm finish through typical sheet metal operations like laser cutting, punching, and bending without degradation. The cold rolling and annealing processes create its characteristic smooth, reflective surface that remains stable during manufacturing. Pre-anodized aluminum features factory-applied oxide coatings that resist scratching during fabrication and maintain uniform color consistency across large panels.

For enclosures requiring clean, professional appearance, 2B stainless steel provides the durability needed for high-touch applications without showing fingerprints or wear patterns. Pre-anodized aluminum works well for chassis and panels where lightweight construction and corrosion protection are priorities, particularly in outdoor or marine environments where standard aluminum would require post-fabrication coating.

Standard mill-finish materials typically require additional operations to achieve comparable surface quality, adding 3-5 days to project timelines and increasing handling complexity during production.

Design Takeaway: Choose 2B stainless steel for applications requiring maximum durability and cleanability. Select pre-anodized aluminum when weight reduction and consistent color appearance are priorities. Both options deliver finished-quality surfaces that eliminate secondary operations.

How Can I Design Parts to Avoid Surface Quality Issues?

Maintain uniform material thickness (±0.1mm/100mm), avoid features smaller than 0.030″, and use bend radii matching sheet thickness to prevent surface defects during fabrication.

- Uniform thickness – Eliminates stress concentrations and warping

- Minimum feature size – Prevents burr formation and edge inconsistencies

- Proper bend radii – Reduces cracking and surface stress marks

Through our design consultation experience, parts with thickness variations create stress points that lead to surface distortion during forming operations. Features smaller than 0.030″ consistently produce burrs or incomplete cuts that compromise edge quality. Simple angled bends with radii matching material thickness distribute stress evenly, preventing the micro-cracking common in tight-radius applications.

For precision enclosures, inconsistent thickness often results in visible oil-canning or surface waves that affect appearance and flatness. Medical device housings require consistent feature sizing to eliminate sharp edges that complicate cleaning protocols and create potential contamination points during manufacturing.

Parts designed without these considerations typically require secondary operations like edge breaking or surface refinishing, extending lead times by 2-3 days while adding quality control complexity.

Design Takeaway: Reserve tight features and sharp bends for non-visible areas, and apply uniform thickness principles across all part geometries. Prevention through design eliminates surface defects more effectively than post-fabrication correction.

How Do I Specify Surface Quality Requirements?

Define target Ra values (specify “Ra 1.6 μm” vs. “smooth finish”), request nitrogen laser cutting for critical edges, and coordinate surface specifications with functional requirements to avoid over-specification.

- Specific Ra targets – Use measurable values instead of subjective terms

- Process specifications – Request nitrogen cutting for oxide-free edges

- Functional coordination – Match surface specs to actual performance needs

In our quoting experience, vague specifications like “good finish” or “smooth surface” lead to interpretation differences and potential rework. Defining specific Ra values enables consistent quality control and eliminates miscommunication between design intent and manufacturing capability. Nitrogen-assisted cutting delivers measurably superior edge quality compared to standard air-assist methods.

For electronic enclosures requiring EMI shielding, specifying Ra values ensures consistent gasket sealing without over-processing non-critical surfaces. Industrial equipment housings benefit from clearly defined finish requirements that balance appearance with cost-effectiveness across visible and hidden features.

Unclear specifications often result in manufacturing delays while clarifying requirements, or expensive over-processing to meet assumed quality expectations rather than actual functional needs.

Design Takeaway: Always specify measurable surface requirements using Ra values, identify which surfaces need premium finishes, and communicate functional reasoning behind specifications. Clear requirements prevent costly misunderstandings during production.

What Surface Finishes Can I Achieve Without Extra Steps?

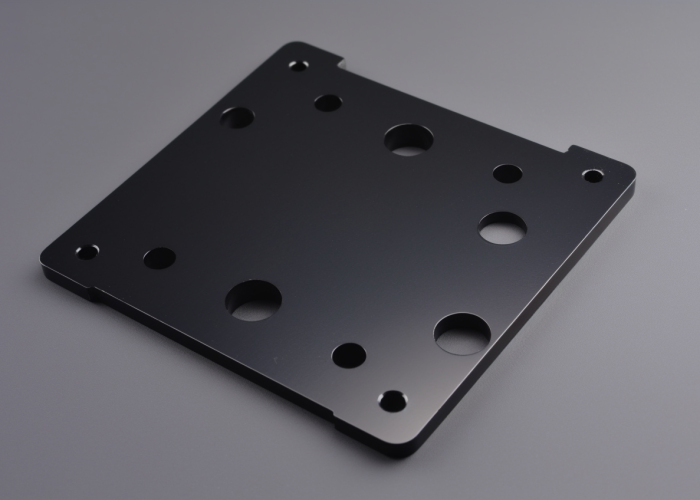

Integrated processes deliver Ra 2.5-3.2 μm matte finishes through bead blasting and consistent edge radius through linear deburring, eliminating tool marks while maintaining dimensional accuracy.

- Matte finish capability – Ra 2.5-3.2 μm uniform appearance

- Edge consistency – Linear deburring maintains ±0.1mm radius tolerance

- Tool mark elimination – Reduces visible marks to <0.03mm depth

From our finishing experience, integrated bead blasting creates uniform surface texture that hides minor imperfections while providing excellent paint adhesion for subsequent coating operations. Linear deburring systems maintain edge consistency across complex geometries without the variation typical of manual operations.

These finishes work particularly well for chassis applications where visual consistency matters more than mirror-like smoothness. The Ra 2.5-3.2 μm range provides non-reflective appearance suitable for electronic equipment while maintaining the dimensional stability required for precise assembly operations.

Secondary finishing operations often introduce handling damage or dimensional changes that require additional inspection steps and extended production timelines.

Design Takeaway: Request integrated finishing for visible surfaces requiring uniform appearance, and specify linear deburring for functional edges. These processes deliver production-ready finishes without separate operations or additional quality risks.

How Do I Protect Surface Quality During Production?

Apply protective films to maintain Ra values within 0.2 μm of original specifications and use non-abrasive foam separators in climate-controlled storage to preserve surface quality for up to 12 months.

- Protective film application – Maintains surface roughness within Ra 0.2 μm tolerance

- Non-abrasive separators – Prevents contact damage during handling

- Climate-controlled storage – Preserves quality for extended periods

From our production experience, protective films applied immediately after fabrication prevent handling scratches and contamination that commonly occur during assembly operations. The films maintain original surface characteristics while allowing normal manufacturing processes like forming and welding. Non-abrasive foam separators eliminate part-to-part contact damage during storage and transportation.

For precision audio faceplates, protective films ensure consistent appearance through multiple handling stages while maintaining the critical surface finish required for professional equipment. Medical device components benefit from contamination-free storage that preserves sterile packaging requirements and eliminates pre-assembly cleaning operations.

Unprotected parts often suffer micro-scratches, fingerprints, or environmental contamination that requires costly refinishing or part replacement during final assembly stages.

Design Takeaway: Specify protective film application for all visible surfaces and request climate-controlled storage for extended lead times. Prevention during production eliminates surface quality degradation more effectively than post-damage restoration.

How Much Can I Save by Avoiding Secondary Operations?

Integrated surface quality approaches reduce post-processing requirements by 60% and lower overall production costs by 20-30%, despite a 15-25% material premium for pre-finished options.

- 60% post-processing reduction – Eliminates most secondary finishing operations

- 20-30% total cost savings – Despite higher material costs

- 15-25% material premium – Offset by operational savings

In our cost analysis experience, eliminating secondary operations reduces both direct finishing costs and indirect expenses like additional handling, inspection, and scheduling complexity. Pre-finished materials typically command higher unit costs but deliver net savings through reduced labor, equipment usage, and quality control requirements.

For prototype development, avoiding secondary operations can reduce lead times by 5-7 days while eliminating the scheduling delays common with multi-step finishing processes. Production runs benefit from simplified workflows that reduce quality variability and eliminate the rework costs associated with finishing defects or handling damage.

Traditional approaches requiring multiple finishing steps often experience compounding delays, quality issues, and cost overruns that exceed the initial material savings from standard finishes.

Design Takeaway: Evaluate total project costs including time, handling, and quality risks rather than just material pricing. Integrated approaches typically deliver superior economics while improving delivery predictability and surface quality consistency.

Conclusion

Integrated surface quality approaches eliminate 60% of post-processing while reducing costs by 20-30% through strategic material selection and optimized design parameters. Focus on pre-finished materials and proper specifications rather than secondary operations for superior results. Contact us to explore manufacturing solutions tailored to your sheet metal surface quality requirements.

Frequently Asked Questions

Yes, specify target Ra values (e.g., “Ra 1.6 μm”) rather than subjective terms like “smooth finish.” This ensures consistent quality control and eliminates interpretation differences during manufacturing.

Protective films maintain surface roughness within Ra 0.2 μm of original specifications for up to 12 months when combined with climate-controlled storage and non-abrasive handling procedures.

Integrated processes deliver Ra 2.5-3.2 μm matte finishes through bead blasting and consistent edge radius through linear deburring, eliminating tool marks while maintaining dimensional accuracy within ±0.1mm tolerance.

Avoid features smaller than 0.030″ and maintain uniform material thickness within ±0.1mm/100mm. Use bend radii matching sheet thickness to prevent cracking and stress concentrations that degrade surface appearance.

Pre-finished materials carry a 15-25% premium over standard mill finishes. However, eliminating secondary operations typically reduces total project costs by 20-30% through saved labor, handling, and scheduling complexity.

Standard mill-finish sheet metal typically achieves Ra 1.6-3.2 μm. Pre-finished materials like 2B stainless steel deliver Ra 0.1-0.3 μm directly from fabrication, eliminating secondary operations while maintaining consistent appearance.