Exploring the robustness of Nylon 6/6? We’ve got you covered with comprehensive insights into its durability and applications. This guide is your ultimate resource for understanding how Nylon 6/6 stands the test of time in various environments.

Yes, Nylon 6/6 is highly durable. It boasts excellent tensile strength, abrasion resistance, and chemical stability and can withstand extreme temperatures and environmental conditions, making it ideal for numerous industrial applications.

Dive deeper into the world of Nylon 6/6 with us. From its core properties contributing to its longevity to real-world applications where its durability is a game-changer, we’ve detailed everything you need to know.

Table of Contents

What Is Nylon 6/6

Nylon 6/6 is a durable synthetic polymer, well-regarded for its high tensile strength, excellent wear resistance, and ability to withstand harsh chemicals and extreme temperatures. Its durability is crucial because it ensures longevity and reliability in demanding applications across various industries, such as automotive, electrical, and consumer goods.

This resilience extends the life of products and enhances safety and performance, making Nylon 6/6 an essential material in sectors that require rigorous use and maintain integrity over time.

What Are the Key Features of Nylon 6/6?

Nylon 6/6 stands out for its exceptional blend of properties:

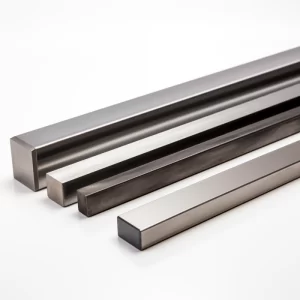

- It exhibits high tensile strength, allowing it to bear significant loads.

- With excellent abrasion resistance, it endures wear and tear well.

- Its superior chemical resistance ensures longevity in harsh environments.

- The material maintains its integrity across a broad temperature range and is suitable for various applications.

- Its low moisture absorption helps preserve dimensional stability and mechanical properties in humid conditions.

- Notably, it is also impact-resistant and able to withstand sudden forces.

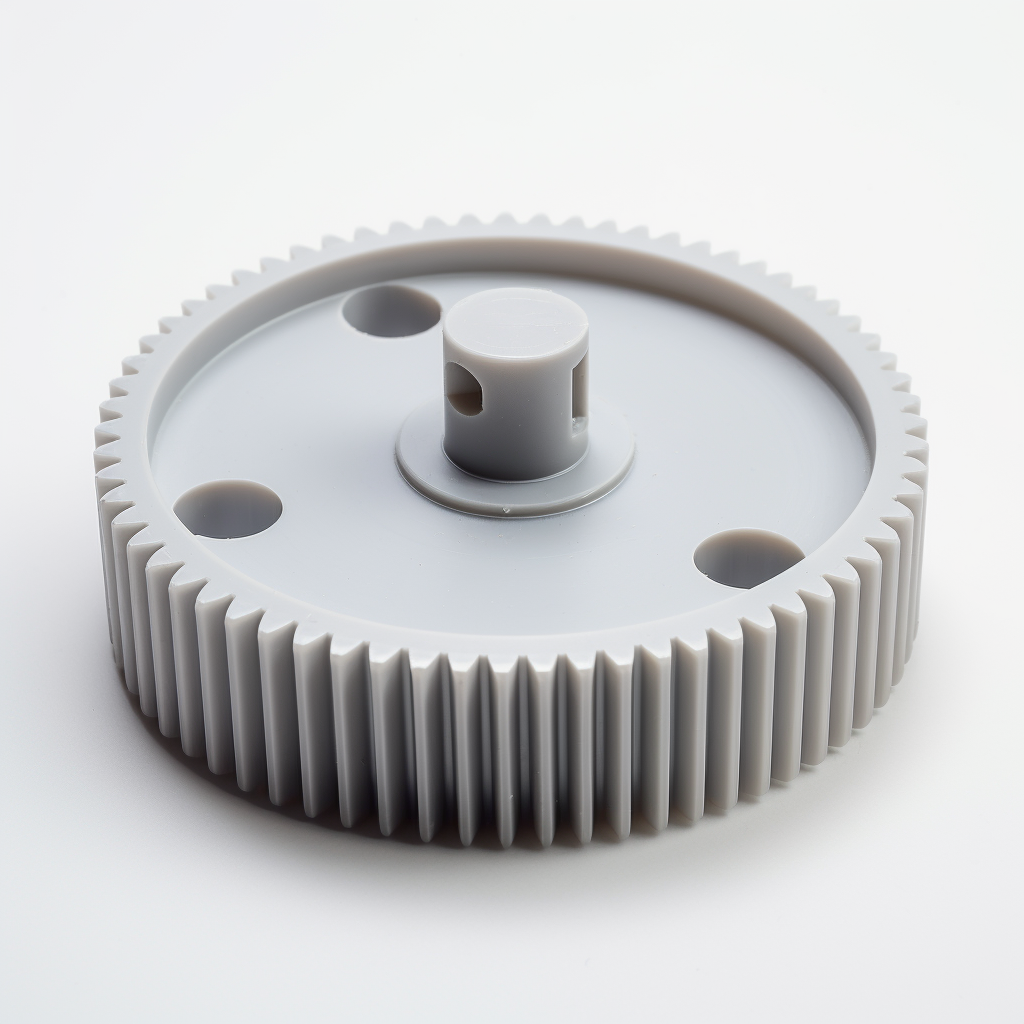

- Furthermore, its electrical insulating properties make it valuable for electronic applications.

These characteristics make it a preferred choice for demanding engineering and industrial uses.

What Factors Can Affect the Durability of Nylon 6/6?

The durability of Nylon 6/6, while impressive, can be influenced by various environmental and usage factors. Prolonged exposure to sunlight can weaken it due to UV radiation. High moisture and humidity levels might affect its strength and shape, although it generally absorbs little water. Its interaction with certain chemicals, like strong acids or bases, can also lead to deterioration, compromising its integrity.

Additionally, Nylon 6/6 can lose some of its resilience when exposed to very high temperatures for extended periods. Finally, continuous or excessive mechanical stress can cause the material to fatigue, potentially leading to cracks or breaks over time. Understanding these factors is key to maximizing the durability and lifespan of Nylon 6/6 products.

Where Is the Durability of Nylon 6/6 Most Valuable?

Nylon 6/6, a high-performing engineering plastic, excels in environments requiring durability, heat resistance, and outstanding chemical resistance. Its polymer chains and amide bonds confer superior mechanical and chemical properties, including abrasion and impact resistance.

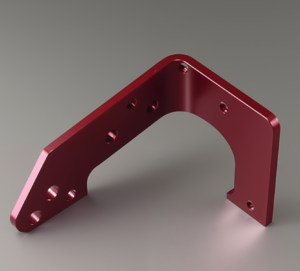

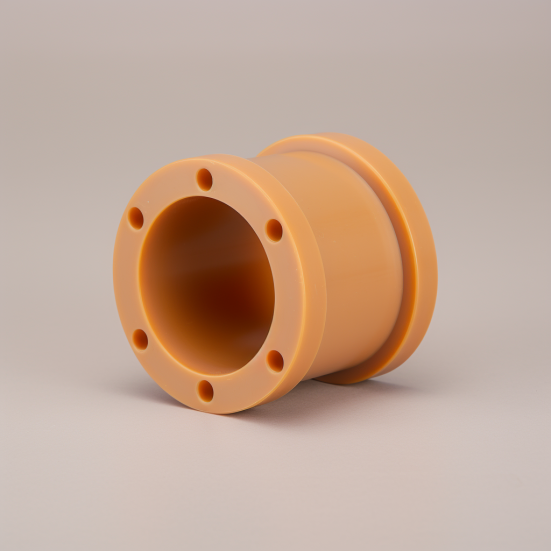

It is ideal for automotive parts like air intake manifolds and industrial applications like conveyor belts. Lower mold shrinkage offers better dimensional stability, crucial for injection-molded parts with complex shapes.

Nylon 6/6’s thermal properties and resistance to high-energy radiation make it suitable for high-temperature applications and electrical components. The material’s ability to absorb moisture without compromising its physical and electrical properties, excellent reactivity, and chemical resistance to most chemicals, including strong mineral acids, underscores its versatility. Whether for machine parts, food packaging, or consumer goods, Nylon 6/6 provides reliability and efficiency, distinguishing it within the nylon family and the broader category of engineering thermoplastics.

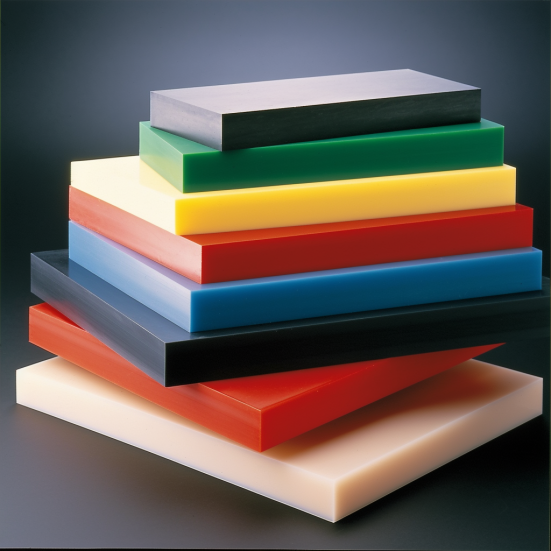

What are the colors of nylon plastic?

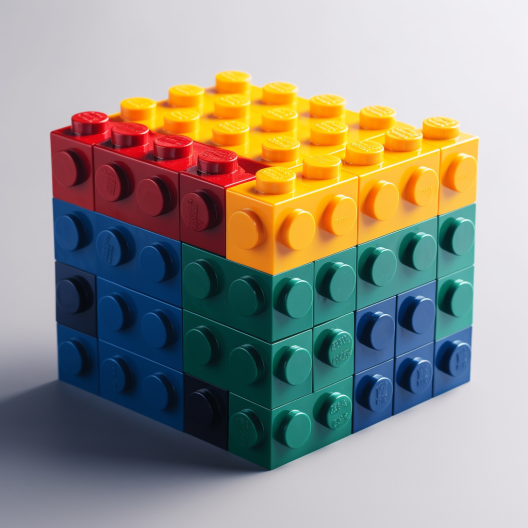

Nylon plastic can be produced in various colors, from natural and transparent to virtually any hue. In its raw state, Nylon often has a milky-white appearance or is transparent, but manufacturers frequently add colorants or dyes to meet specific design criteria.

This versatility in coloring allows Nylon to be used in applications requiring specific aesthetics and functional properties. From bright colors for consumer products like toys and kitchen utensils to more subdued tones for industrial and automotive components, the color possibilities for Nylon plastic are nearly limitless.

What's the difference between nylon 6 and nylon 6 6?

Nylon 6 and 6,6 differ mainly in their chemical structures and resulting properties. Nylon 6 is made from a single type of monomer through ring-opening polymerization, leading to higher moisture absorption and better impact resistance, making it ideal for flexible applications.

Nylon 6,6, created from two types of monomers via condensation polymerization, boasts a higher melting point and greater tensile strength, suited for high-performance needs like automotive parts and industrial machinery—their choice hinges on the application’s strength, flexibility, and thermal resistance requirements.

What are some uses for Nylon 66?

Nylon 6,6, with its semi-crystalline structure and robust properties, is pivotal in industries demanding high performance and durability. Its standout features include outstanding resistance to chemicals and high impact, making it a staple in the automotive industry for parts like engine covers and fuel tanks. This thermoplastic’s superior abrasion resistance and tensile modulus are enhanced by its complex chemical structure, including carbon atoms and glass fibers, ensuring it remains abrasion-resistant and can withstand significant stress without cracking.

Its chemical resistance and stable physical properties, even when exposed to moisture, make Nylon 6,6 ideal for electrical components and consumer goods, where reliability is paramount. The material’s effectiveness in industrial applications is also notable, benefiting from its excellent flow in injection molding processes and greater mold shrinkage control. From textiles to packaging, Nylon 6,6’s adaptability, characterized by its amide bond and polymer backbone, showcases its broad utility across various applications, underscoring its significance as a versatile and high-performing material.

How Does Nylon 6/6 Compare to Other Nylons in Durability?

Nylon 6/6 is often compared to other nylons in terms of durability and stands out for several reasons. It has a higher melting point and better resistance to wear and abrasion than many other nylon variants, such as Nylon 6. This makes it more suitable for critical heat resistance and mechanical strength applications.

Additionally, Nylon 6/6 exhibits superior tensile strength and stiffness, lending it greater durability under stress and load. Its chemical resistance is also notable, particularly against automotive oils and other common chemicals, which is why it finds extensive use in the automotive and electrical industries.

While Nylon 6 absorbs more moisture, which can confer flexibility and impact resistance, Nylon 6/6 maintains better dimensional stability and lower moisture absorption, making it preferable in environments where changes in humidity are a concern. Overall, Nylon 6/6’s blend of thermal stability, mechanical strength, and chemical resistance often makes it the preferred choice for high-performance applications requiring long-term durability.

How to Maintain the Life of Nylon 6/6 Products?

To ensure the longevity of these thermoplastic materials, incorporating a few key practices tailored to their specific properties is essential:

1. Shield from UV Rays: Protect items from direct sunlight to prevent material degradation influenced by UV exposure, safeguarding their reactivity and chemical properties.

2. Chemical Caution: Avoiding prolonged contact with harsh chemicals is crucial despite their better chemical resistance. The material’s resistance to acids and its ability to withstand high impact is significant, but care should still be taken to prevent exposure that could lead to stress cracking.

3. Manage Moisture: Controlling moisture content is key, as absorption can impact the material’s structural integrity despite its good abrasion resistance. Keeping items dry maintains their lustrous surface finish and prevents ring breaks, a common issue with less durable materials.

4. Temperature Guidelines: Adhering to recommended temperature ranges ensures the material retains its better stiffness and very good flow characteristics, preventing premature failure.

5. Soft Cleaning: Use mild detergents to maintain the surface and internal structure, taking advantage of the material’s good abrasion resistance.

6. Considerate Use: Gentle handling is advised to leverage the material’s durability and impact modifiers, designed to absorb and dissipate energy to prevent damage.

These materials, developed from the condensation polymerization of one or two monomers, including adipic acid, possess unique functional groups that confer specific advantages, such as improved stiffness and resistance profiles. By following these maintenance tips, the intrinsic qualities of these materials, reflective of advancements in both East and West Germany’s historical contributions to polymer science, can be preserved for extended use.

Conclusion

In conclusion, Nylon 6/6 stands out because it’s stronger, lasts longer, and can handle tough conditions better than many other types of nylon. It’s great for things like car parts, electrical gadgets, and other products that need to be reliable over time. This makes it a top choice for making durable items that need to perform well under pressure and last a long time.

Frequently Asked Questions

Nylon 6 is used in a wide range of applications due to its excellent performance/cost ratio. It finds applications in the automotive, transportation, electrical & electronics, and consumer goods industries, among others.

Yes, nylon 6 is used in clothing. It is valued for its strength, elasticity, and resistance to abrasion and chemicals, making it suitable for various textiles and garments.

Yes, polyamide 6 is the same as nylon 6. It is also known as polycaprolactam and is synthesized by ring-opening caprolactam polymerization.

Yes, nylon 6,6 is generally considered stronger than nylon 6,10. Nylon 6,6 has a higher melting point and processes at a higher temperature, contributing to its strength and durability. Nylon 6,10, while strong, retains its room temperature toughness at low temperatures better than nylon 6 or 6,6 but does not match the overall strength of nylon 6,6.

Nylon 6,6 is widely used in applications requiring high strength and stiffness, good abrasion and wear resistance, and excellent thermal properties. Common uses include automotive components, electrical insulation, and consumer goods.

PA66 (polyamide 6-6 or nylon 6-6) and nylon (often referring to nylon 6) differ primarily in their synthesis. PA66 is made from hexamethylenediamine and adipic acid, resulting in a polymer with slightly different properties, such as higher melting point and possibly better wear resistance compared to nylon 6, which is made from caprolactam.