Cutting tools might not get the limelight, but they’re the unsung heroes in the world of machining. From the tiniest drill bit to the most massive milling cutter, these tools have shaped civilizations, powered industries, and made modern life possible.

Table of Contents

Basics of Cutting Tools: More Than Just Sharp Objects

What Exactly is a Cutting Tool?

At its core, a cutting tool is a device used to remove material from a workpiece. It generates a force strong enough to shear off bits of material, giving the workpiece its desired shape. Whether drilling, turning, or milling, the cutting tool does the heavy lifting.

Cutting Tool vs. Machine Tool: Clearing the Confusion

While both are integral to the machining process, there’s a clear distinction. A machine tool, like a lathe or a milling machine, holds and moves the workpiece or the cutting tool.

On the other hand, the cutting tool is the star player that directly interacts with the material, making precise cuts to shape it.

The Multifaceted Role of Cutting Tools

Cutting tools aren’t just about slicing and dicing. They play a pivotal role in:

– Shaping: Giving raw materials a new form or profile.

– Resizing: Adjusting the size of a workpiece to meet specific dimensions.

– Finishing: Providing that final touch to ensure the surface is smooth and meets the desired finish.

From the metal cutting processes in massive factories to creating intricate jewelry pieces, cutting tools ensure precision, efficiency, and perfection in every cut.

Materials Used in Cutting Tools

From Steel to Diamond

Every cutting tool, whether it’s shaping a delicate piece of jewelry or slicing through hardened metal, is crafted from materials best suited for the job. Here’s a look at some of the most common ones:

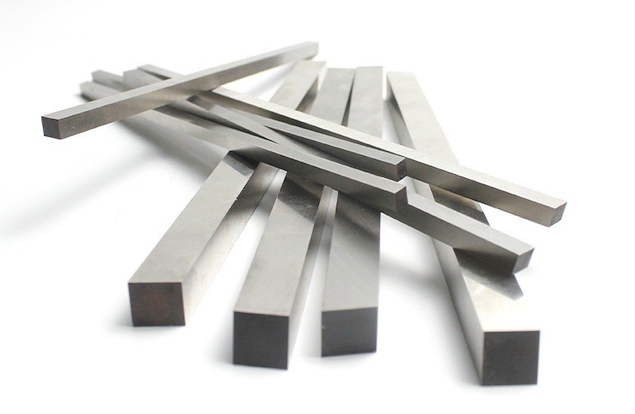

– High-Speed Steel (HSS): A favorite in many machine shops, HSS balances hardness and toughness. It’s versatile, cost-effective, and can withstand higher temperatures without losing its edge.

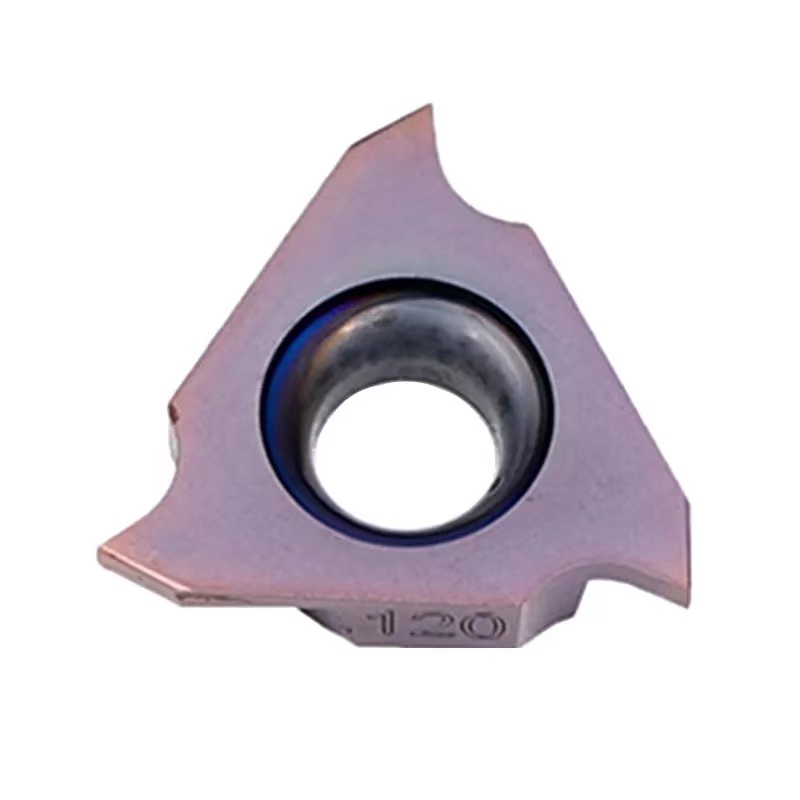

– Carbide: When it comes to wear resistance, carbide is king. Tungsten carbide tools, for instance, can maintain their sharpness far longer than their HSS counterparts. They’re a bit pricier but offer longevity in high-wear applications.

– Ceramics: Think beyond your kitchen tiles! In the cutting tools, ceramics like alumina and silicon nitride are valued for their incredible heat resistance and hardness. They’re perfect for high-speed operations but can be brittle.

– CBN (Cubic Boron Nitride): Second only to diamond in hardness, cBN is a beast when it comes to machining hardened steels. It offers excellent wear resistance and can withstand high temperatures.

– Diamond: The hardest known material to man, diamond-tipped cutting tools offer unparalleled wear resistance. They’re especially favored for non-ferrous materials like aluminum and copper.

Choosing the Right Material

The choice of cutting tool material isn’t arbitrary. It’s influenced by:

– Hardness: The ability to resist deformation.

– Toughness: The tool can absorb energy and plastically deform without breaking.

– Wear Resistance: How well the tool can resist wear and tear over time.

Classification of Cutting Tools

Single-Point vs. Multi-Point: The Cutting-Edge Difference

– Single-Point Tools: As the name suggests, these have one main cutting edge. Think of turning tools used in lathes. They’re all about linear motion, removing material layer by layer.

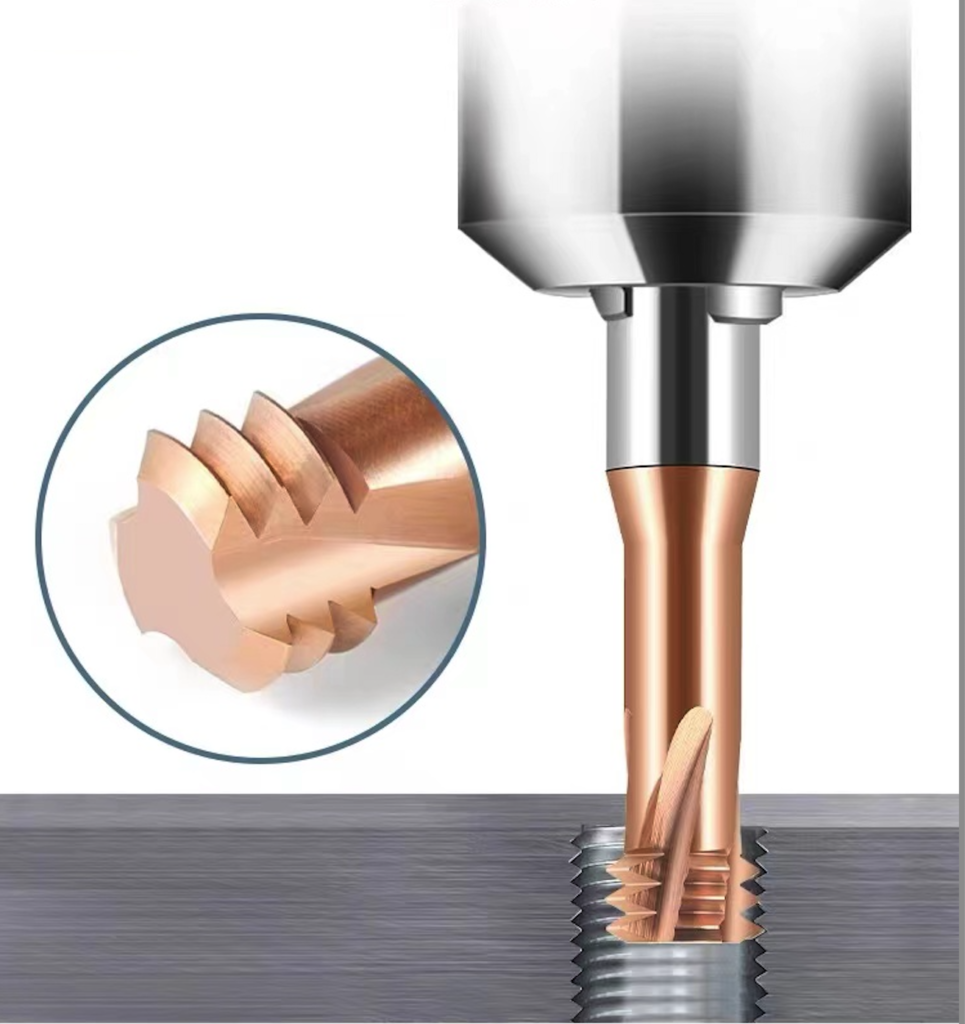

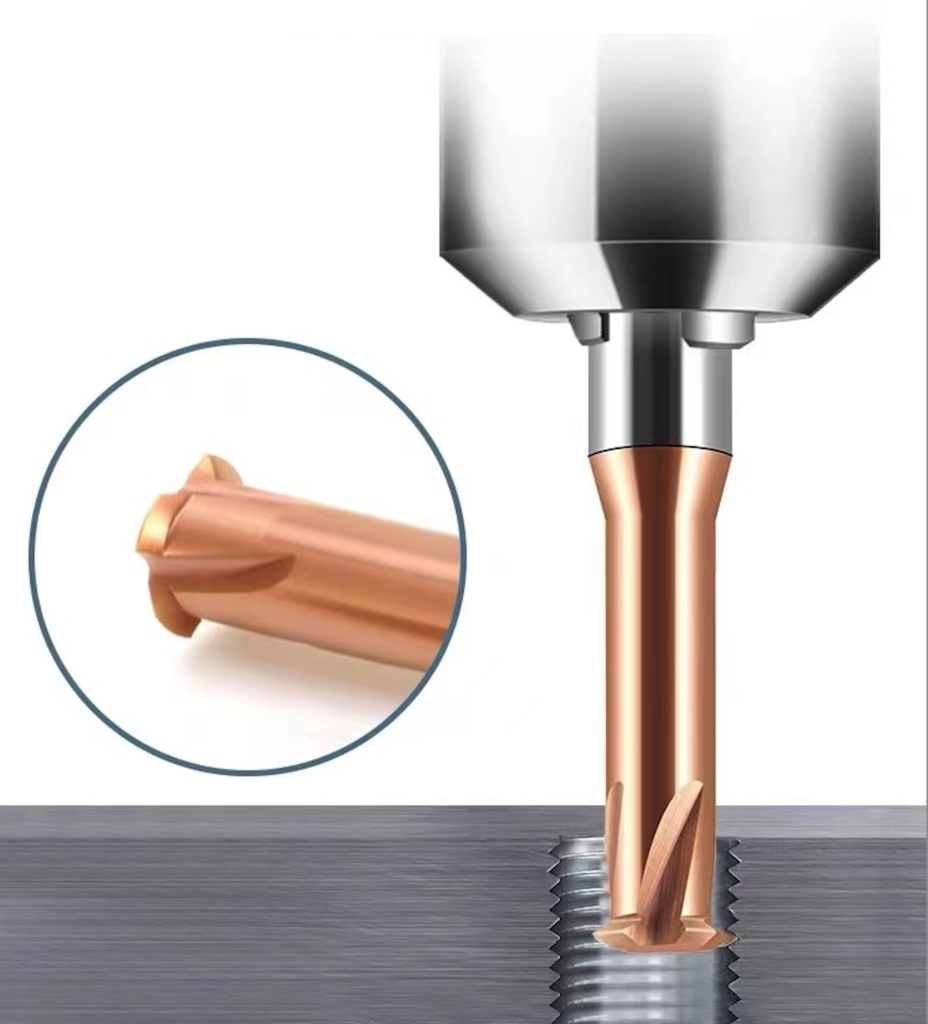

– Multi-Point Tools: These tools have multiple cutting edges working simultaneously. Milling cutters are a classic example, where several teeth work together to shape the workpiece.

Motion Matters: Linear vs. Rotary

– Linear Motion Tools: These tools move in a straight line. Turning tools, for instance, follow a linear path to shape materials.

– Rotary Motion Tools: These tools rotate. Milling cutters and drills fall into this category, spinning to remove material.

Tools Tailored for Specific Operations

– Drilling: All about making holes. Drills are the go-to tools here, designed to pierce through materials.

– Milling: It’s versatile and can perform operations like slotting, side and face milling, and contouring.

– Turning: This operation is about removing material from a rotating workpiece. Turning tools and lathes are central players here.

From the materials they’re made of to their specific applications, cutting tools are as diverse as the tasks they perform. Whether you’re drilling a hole or crafting a masterpiece, there’s a tool tailored for the job.

Cutting Tool Geometry

Why Tool Angles Matter in Machining

Every artisan knows that the angle of a chisel or the tilt of a blade can make all the difference. In the realm of metal cutting, this principle is magnified a hundredfold. The geometry of a cutting tool isn’t just about aesthetics; it’s about precision, efficiency, and achieving the desired shape of the final product

Dive into the Angles: Rake, Clearance, and More

– Rake Angle: This is the angle between the tool face and the line of action of the cutting action. A positive rake angle can make cutting smoother, while a negative one can increase tool strength. It plays a pivotal role in determining how the tool will interact with the workpiece and the kind of chip it will produce.

– Clearance Angle: Consider this the “breathing room” angle. It ensures the only part of the tool that touches the workpiece is the cutting edge. It prevents friction, leading to tool wear and poor surface finish.

– Other Geometries: Every angle has a role, from the lip angle in drills to the approach angle in turning tools. Each one is meticulously designed to optimize the cutting process.

Geometry's Role in Chip Formation and Heat

The geometry of a cutting tool directly influences the type and shape of chips produced during the metal cutting process. Efficient chip formation is crucial for smooth machining and ensuring the heat generated is carried away by the chips, preventing damage to both the tool and the workpiece.

Cutting Tool Wear and Life

The Inevitable Wear: Types and Causes

Every cutting tool, no matter how robust, faces wear and tear. Recognizing the types of wear can help in timely interventions and tool replacements.

– Flank Wear: This occurs on the tool’s flank or side and can affect the dimensional accuracy of the machined part.

– Crater Wear: Found on the tool’s face, it’s caused by the high temperatures and pressures of the cutting process.

– Notch Wear: This type of wear occurs at the depth of the cut line and can lead to sudden tool failures if not addressed.

Factors Influencing Tool Wear

The rate at which a tool wears is about more than just its material or quality. Several external factors play a role:

– Speed: Higher cutting speeds can increase wear.

– Feed: A higher feed rate can lead to more aggressive wear.

– Depth of Cut: Deeper cuts can exert more pressure on the tool, leading to faster wear.

– Work Material: Some materials are more abrasive or harder to cut, increasing tool wear.

Enhancing Tool Life: Strategies to Combat Wear

No one likes frequent tool changes. It’s time-consuming and costly. Here are some strategies to maximize tool life:

– Coatings: Materials like titanium nitride can be coated on tools to reduce wear.

– Optimized Cutting Parameters: Adjusting speed, feed, and depth of cut can balance efficiency and wear.

– Coolants and Lubricants: These can reduce heat and friction, two primary culprits of tool wear.

Remember, the longevity of a cutting tool isn’t just about its inherent quality but also about how it’s used. Proper understanding and adjustments can make all the difference!

Cutting Fluids and Their Role

In the world of tool cutting, it’s not just about the sharpness of the tool bits or the precision of the machine tools. The fluids accompanying the cutting process are pivotal in ensuring everything runs smoothly. Think of them as the silent guardians protecting the tool and the workpiece.

Diving into the Types of Cutting Fluids

– Water-Based Fluids: These are primarily made up of water, making them excellent for cooling. They’re often used in milling operations and with rotary cutters.

– Oil-Based Fluids: As the name suggests, these are primarily made up of oils. They’re fantastic for lubrication, especially in turning operations where the tool must glide smoothly.

– Synthetic Fluids: These are engineered fluids designed to offer the best of both worlds. They can cool, lubricate, and even prevent rust.

The Triple Benefits of Cutting Fluids

1. Cooling: High-speed tool cutting generates heat. Cutting fluids dissipate this heat, ensuring the tool doesn’t lose its sharp edge, and the workpiece doesn’t get damaged.

2. Lubrication: This reduces friction between the tool and the workpiece, ensuring smoother cuts and longer tool life.

3. Chip Removal: As tools make their cuts, they produce chips. Fluids help flush these away, ensuring they don’t interfere with subsequent cuts.

Advanced Cutting Tool Technologies

In the quest for better performance, tool-cutting tools have evolved. One significant advancement is the use of coatings. Coated tools, especially those with cemented carbide, offer enhanced wear resistance, allowing them to maintain a sharp cutting edge for longer.

Nanostructured and Diamond-Coated Tools

– Nanostructured Tools: These tools have a structure refined at the nanoscale. This gives them high hardness and makes them sufficiently hard to resist wear even under intense conditions.

– Diamond-Coated Tools: Diamonds are the hardest known material. So, it’s no surprise that tools coated with diamonds offer unparalleled wear resistance and longevity. They’re the best example of how advanced tool cutting has become.

Peering into the Future

The world of cutting tools is ever-evolving. With the rise of automation and AI, we can expect tools that can self-adjust, ensuring the best cuts every time. Moreover, as materials science progresses, we might see tools made of materials we have yet to discover. The future is, without a doubt, sharp and exciting!

Safety and Best Practices

Proper handling is paramount when cutting tools, especially those with a sharp edge. Each tool must be stored to protect its cutting edges, whether a single-point cutting tool or a multi-point cutting tool. Tool holders or dedicated storage units in a machine shop can prevent accidental damage. Remember, a tool is only as good as its edge!

Regular Inspection and Maintenance

Just like a doctor uses a stethoscope to check a heartbeat, a machinist must regularly inspect cutting tools. Whether checking the cutting edge of a grinding wheel or the blades of fly cutters, regular inspection ensures that every cutting action is precise. Moreover, tools like end mills and drilling machines benefit immensely from routine maintenance, ensuring they perform at their peak.

Conclusion

The Unwavering Significance of Cutting Tools

From point-cutting to single-point-cutting tools, the manufacturing world owes precision and efficiency to these marvels. They’re not just tools; they’re the essence of every specific shape we craft and every masterpiece we create. With every single pass, from the sharp cutting edges to the wedge-shaped designs, these tools redefine perfection.

Crafting the Future with Every Cut

The vast types of cutting tools, from drilling machines to abrasive materials, play a pivotal role in shaping our world. Whether it’s the tool body intricately crafting common materials or the precision of polycrystalline diamond tools, the future of manufacturing is being carved today. As you use these tools, from saw blades to knives, remember: Every cut is a step towards a brighter, sharper tomorrow.

Frequently Asked Questions

Single-point cutting is when a tool with a single sharp cutting edge removes material from a workpiece. It’s commonly seen in operations like turning, where the tool’s cutting edge interacts with the workpiece at a single point.

Blades and cutters interact with metal by applying force at their cutting edges. The sharpness and geometry of the edge, combined with the tool’s motion, remove and shape the metal to the desired form.

Abrasive material, like that found on a grinding wheel, doesn’t cut in the traditional sense. Instead, it wears away at the material through friction, refining surfaces, or shaping them.

Point cutting tools, as the name suggests, have a singular point that engages with the material. In contrast, other cutting tools might have multiple edges or points interacting with the material simultaneously.

Machine tools are the backbone of the manufacturing industry. They’re used for cutting, shaping, and finishing materials. With precise cutting edges, they ensure accuracy and repeatability in production processes.

A grinding wheel uses abrasive action rather than a sharp cutting edge to remove material. It’s made of abrasive material and is used to refine surfaces and sharpen blades.

The cutting edge of a tool determines how effectively it can cut materials. A sharp and well-maintained edge ensures clean, efficient cuts, reducing waste and improving the finish of the material.

With their tapered geometry, Wedge shaped tools allow effective cutting action. The shape concentrates force at the tip, allowing precise cuts and better penetration into materials.

A drilling machine is specifically designed to create holes in materials. While other machine tools might shape, cut, or finish materials, drilling machines focus on bore creation using sharp blades or bits.

Tools with two cutting edges offer balanced cutting action, reducing vibrations and ensuring symmetrical material removal. This can be especially beneficial for tasks requiring precision and balance.