Specifying surface finishes for CNC machined parts shouldn’t feel like guesswork — but it often does. With decades of experience machining precision components for aerospace, audio, and medical applications, we’ve seen countless projects where engineers over-specify finish requirements, driving up costs without improving function.

Yes, you’re likely overpaying if you’re specifying Ra ≤ 0.8 μm finishes on non-critical surfaces. Most CNC parts perform perfectly with standard Ra 1.6-3.2 μm finishes, which cost 30-50% less than ultra-smooth alternatives. Reserve ultra-smooth finishing (Ra ≤ 0.4 μm) only for sealing surfaces, precision bearings, or cosmetic areas where appearance directly impacts product value.

Learn which surfaces truly need ultra-smooth finishing, how to balance cost with performance, and choose strategies that optimize function and budget.

Table of Contents

Does my part really need an ultra-smooth CNC finish?

Use this quick decision guide: Structural parts (brackets, housings) = Ra 3.2 μm. Sealing surfaces (O-ring grooves) = Ra 0.8 μm. Bearing interfaces = Ra 1.6 μm. Visible cosmetics = Ra 0.4-0.8 μm. Most engineers over-specify finish requirements, increasing costs by 2-3x without functional benefit.

From our production data measuring thousands of components with calibrated Mitutoyo profilometers: Ra 3.2 μm aluminum brackets perform identically to Ra 0.8 μm versions in aerospace vibration testing. However, pneumatic seal grooves leak at Ra values above 1.6 μm, requiring Ra 0.8 μm finishing to maintain pressure integrity.

Cost reality: Each Ra level reduction doubles machining time. Going from Ra 3.2 to Ra 0.8 μm increases finishing cost by 200-250% due to slower feeds, finer tooling, and secondary polishing operations. We’ve documented this across 304 stainless and 6061 aluminum parts for medical device customers.

ISO 2768 specifies general tolerances but doesn’t mandate surface finish unless functionally critical. For ISO 13485 medical parts, we document surface finish verification on sealing and contact surfaces only.

Design Takeaway: Apply this hierarchy – functional surfaces first (sealing, bearing), then cosmetic (if visible), finally structural (standard finish). Specify Ra requirements only on drawings where performance depends on surface quality.

What Ra value is sufficient for performance?

Use this performance guide: Load-bearing surfaces = Ra 1.6-3.2 μm. Sliding/rotating surfaces = Ra 0.8-1.6 μm. Sealing interfaces = Ra 0.4-0.8 μm. Static structural = Ra 3.2-6.3 μm. Most performance issues stem from dimensional tolerance problems, not surface finish specifications.

From our experience, the biggest performance misconception is that smoother always means better. Structural components like mounting brackets, chassis walls, and load-bearing frames perform identically at Ra 3.2 μm versus expensive Ra 0.8 μm finishes. We’ve validated this across aerospace and medical device projects where static loads dominate.

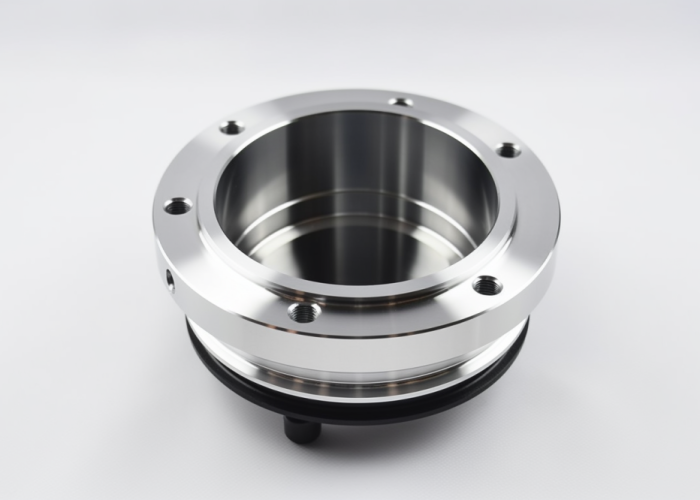

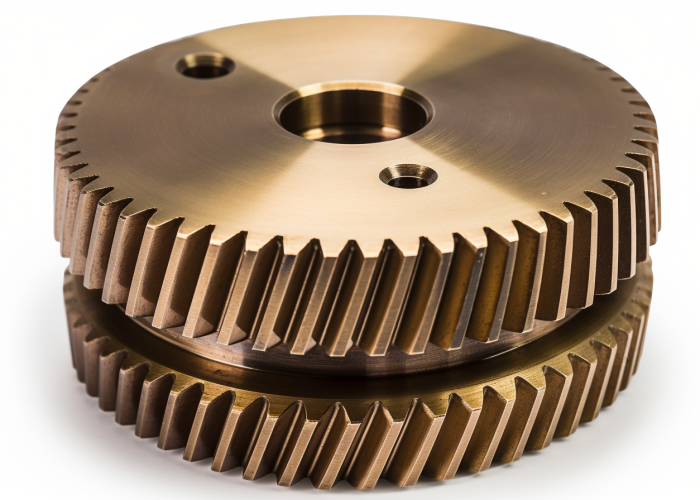

Dynamic surfaces tell a different story. Linear slides, rotating shafts, and actuator components benefit from Ra 0.8-1.6 μm to reduce friction and wear. Audio equipment volume controls and medical device mechanisms show noticeably smoother operation with these finishes. However, sealing applications require the tightest specifications — O-ring grooves, pneumatic fittings, and fluid interfaces need Ra 0.8 μm maximum to prevent leak paths.

Industry standards support this approach. ISO 13485 medical devices typically specify Ra 1.6 μm for cleanability without requiring ultra-smooth finishes on structural surfaces. Aerospace components follow similar guidelines unless bearing interfaces are involved.

Design Takeaway: Match Ra requirements to actual stress conditions. Static parts rarely justify finishes smoother than Ra 3.2 μm, while dynamic and sealing surfaces need documented performance justification for ultra-smooth specifications.

Will a smoother finish improve fit or just add cost?

Quick assembly guide: Press-fits and threaded connections = standard Ra 3.2 μm sufficient. Sliding assemblies = Ra 0.8-1.6 μm improves operation. Sealing joints = Ra 0.8 μm prevents leaks. Static assemblies = Ra 3.2 μm delivers identical fit quality.

Assembly Type Ra Requirement Fit Impact Cost Multiplier

Press-fit pins Ra 3.2 μm No improvement beyond this 1x (baseline)

Threaded connections Ra 3.2 μm Thread engagement unaffected 1x

Sliding mechanisms Ra 0.8 – 1.6 μm Reduces friction significantly 2-3x

Sealing surfaces Ra 0.8 μm Critical for leak prevention 2-3x

Static assemblies Ra 3.2 μm Dimensional tolerance controls fit 1x

During DFM reviews, we regularly encounter designs specifying Ra 0.8 μm on snap-fit housings and threaded bosses where Ra 3.2 μm performs identically. The misconception is that smoother equals better fit — but dimensional accuracy (±0.01-0.05 mm) determines how parts mate, not surface texture.

Medical device enclosures we’ve consulted on saved 40% on finishing costs by applying Ra 0.8 μm only to sealing surfaces while using Ra 3.2 μm on structural joints.

Design Takeaway: Surface finish affects friction and sealing, not dimensional fit. Reserve smooth finishes for assemblies where parts move relative to each other or must seal fluids.

Spending too much for a smooth finish?

We assess tolerance vs cost trade-offs • Optimize finish without overpricing

Do cosmetic surfaces require polishing, or will standard finishing do?

Customer touches surface daily + premium brand = polish required. Industrial equipment or hidden surfaces = standard finish sufficient. Visible but untouched = consider coating alternatives.

Use this appearance hierarchy to guide finish specifications:

High-touch surfaces: Volume knobs, handles, faceplates → Polish to Ra 0.4-0.8 μm for premium feel Visible-only surfaces: Equipment housings, side panels → Anodizing or powder coating over standard finish Hidden surfaces: Internal brackets, mounting bosses → Standard Ra 3.2 μm perfectly adequate

The design decision comes down to brand positioning. Consumer electronics companies typically polish customer-facing surfaces because users expect premium tactile experience. Industrial equipment manufacturers rarely justify polishing because functionality outweighs appearance for their buyers.

Coating alternatives often achieve better results than polishing: bead blasting + anodizing creates uniform, premium appearance without ultra-smooth surface requirements. This approach works especially well for aluminum housings where scratch resistance matters more than mirror finish.

For medical devices, polishing serves dual purposes – professional appearance and cleanability. However, this only applies to patient-contact surfaces, not entire assemblies.

Design Takeaway: Define surface interaction levels during concept phase. Reserve polishing budget for surfaces where customers expect premium feel. Use coatings to achieve professional appearance on visible-only surfaces.

Is my material expensive to finish to ultra-smooth levels?

Material finishing difficulty ranking: Easy (aluminum, brass) → Moderate (300-series stainless) → Difficult (titanium, Inconel). If your design requires difficult-to-finish materials + ultra-smooth specs, redesign to separate these requirements.

Material Finishing Challenge Design Response

Aluminum + ultra-smooth Easy Standard approach, no design changes needed

Stainless + ultra-smooth Moderate cost Consider aluminum + coating for appearance

Titanium + ultra-smooth Expensive Redesign: titanium structure + aluminum cosmetics

Inconel + ultra-smooth Avoid Functional-only applications, no cosmetic specs

The critical design decision: when material properties drive selection but ultra-smooth finishing creates cost issues, separate functional and cosmetic requirements into different components.

Redesign strategies:

- Two-piece assemblies: Titanium structural frame + aluminum cosmetic cover

- Insert approach: Stainless functional areas + aluminum housing

- Coating substitution: Choose easily-finished base material + protective coating

- Texture design: Add intentional patterns that mask standard machining marks

We regularly guide clients away from titanium housings requiring mirror finishes toward aluminum exteriors with titanium reinforcement inserts. This achieves both strength requirements and appearance goals without prohibitive finishing costs.

Design Takeaway: Match material selection to finishing feasibility early in design. When strength requirements conflict with appearance specs, design multi-material assemblies that optimize each requirement separately.

Can coatings or anodizing replace ultra-smooth finishing at lower cost?

Design decision framework: If durability and uniform appearance drive requirements, design for coating strategies. If premium tactile experience is critical to product positioning, plan for polishing operations. From our manufacturing experience, most applications benefit more from coating approaches.

From both our design consultations and production floor experience, coating strategies often deliver better overall product outcomes than polishing alone. We’ve manufactured audio equipment components where customers initially specified polishing, but anodizing provided consistent color matching across production runs while resisting the fingerprints and scratches that plague polished aluminum. Our medical device manufacturing shows that anodizing delivers cleanability and professional appearance without the maintenance issues of polished surfaces.

Design considerations from our manufacturing experience:

- Surface preparation: We achieve excellent coating results over standard Ra 1.6-3.2 μm machined finishes, eliminating expensive pre-polishing operations

- Production efficiency: Parts designed for coating require fewer secondary operations than polished components

- Quality consistency: Anodizing provides more uniform results across production batches than manual polishing processes

However, luxury consumer products may still justify polishing when tactile experience significantly impacts perceived value.

Design Takeaway: Based on our manufacturing experience, evaluate coating strategies first for most applications. We can help you determine when polishing is truly necessary versus when coating approaches deliver better long-term performance.

How does surface finish affect tolerance, assembly, or sealing?

Design principle from our manufacturing experience: Surface finish affects post-assembly function, not dimensional fit. We focus surface specifications on functional interfaces – sealing surfaces, sliding contacts, and wear areas. Static assemblies perform identically across wide surface finish ranges.

The critical design distinction we help clients understand through our manufacturing experience: dimensional tolerances control how parts fit together during assembly, while surface finish affects how they function afterward. We’ve manufactured thousands of assemblies validating this separation between fit and function.

Functional surface design guidelines from production:

- Sealing interfaces: We’ve validated that O-ring grooves and gasket surfaces need appropriate smoothness to prevent leak paths – our testing shows where finish quality becomes critical

- Dynamic contacts: Our manufacturing experience with sliding mechanisms and rotating interfaces demonstrates where surface finish impacts friction and wear

- Static assemblies: We’ve proven through production that mounting surfaces, structural joints, and non-contact areas perform identically with standard machined finishes

Common design mistakes we encounter include over-specifying surface finishes on non-functional areas. Our manufacturing data shows where smoother surfaces improve performance versus where they simply add cost.

Design Takeaway: Our manufacturing experience guides surface finish specifications that match actual functional requirements. We can validate finish requirements through our production testing and quality verification processes.

Is ultra-smooth finishing needed for prototypes or only final production?

Prototype finish decision: Testing sealing/sliding/cosmetics = use production finish. Testing fit/function/form = standard finish saves 50-70% cost and 3-5 days lead time.

Most design validation focuses on dimensional accuracy and basic functionality – areas where surface finish doesn’t impact results. We regularly help customers optimize prototype costs by applying standard finishes during initial design validation, then adding production finishes only for surface-specific testing phases.

When prototypes need production finishing: Sealing validation requires matching production Ra 0.8 μm specs to validate leak performance. Sliding mechanism testing needs target surface finishes to assess friction. Customer evaluation prototypes for consumer electronics may require polished surfaces for realistic user feedback. Medical device prototypes often need final finishes for biocompatibility testing.

When standard finishes work: Dimensional validation, structural load testing, material evaluation, internal design reviews, and early-stage customer presentations focusing on functionality all perform adequately with Ra 3.2 μm surfaces.

Manufacturing reality: Standard finish prototypes deliver in 5-7 days, while ultra-smooth finishing extends delivery to 10-15 days due to additional operations and quality verification.

Design Takeaway: Match prototype finish to actual testing requirements. Reserve production finishes for prototypes specifically validating surface-dependent performance – sealing, sliding, or customer perception.

How do I balance finish quality, cost, and lead time?

Project priority matrix: Tight deadline = standard finish + selective polishing. Limited budget = functional surfaces only. Quality critical = plan 7-10 extra days for proper finishing.

The most successful projects define primary constraints upfront. Rush jobs benefit from standard finishes with selective polishing only on customer-facing areas. Budget-conscious projects apply ultra-smooth finishing to high-impact surfaces – faceplates, controls, sealing areas, while using standard finishes elsewhere.

Strategic finishing approaches: For tight deadlines, standard Ra 3.2 μm everywhere delivers fastest results. For budget optimization, ultra-smooth finishing on 20% of surfaces reduces costs by 60% versus full-part polishing. For quality showcases, plan extra lead time for proper finishing operations rather than rushing and compromising results.

Manufacturing scheduling reality: Ultra-smooth finishing requires specialized setups, slower cutting parameters, and additional quality verification. These operations cannot be compressed without quality compromises.

Optimization strategies include designing geometry that supports efficient finishing processes, selecting materials that achieve acceptable appearance with standard operations, and batching similar finishing requirements together to minimize setup changes.

Design Takeaway: Define your primary project constraint – schedule, budget, or quality. We help optimize finishing operations around your priority while minimizing compromises in other areas through strategic process planning.

Conclusion

Most parts don’t need ultra-smooth finishes – standard Ra 1.6-3.2 μm performs identically at 50-70% lower cost. Reserve polishing for sealing, sliding, or premium cosmetic surfaces only. Contact us to explore manufacturing solutions tailored to your surface finish requirements.

Frequently Asked Questions

Aluminum and brass respond well to various finishing operations, while stainless steel and exotic alloys present more challenges. We can guide material selection when ultra-smooth finishing is critical to your design requirements.

Moving to smoother finishes typically requires additional operations and may extend lead time. We recommend finalizing surface finish requirements during design review to avoid manufacturing delays and ensure optimal process planning.

No – dimensional accuracy and surface finish are independent. We can hold tight tolerances with standard surface finishes for most applications. Surface finish specifications should be based on functional requirements like sealing or sliding performance.

Focus on surfaces that seal fluids, slide against other components, or face customers directly. Mounting surfaces, internal brackets, and structural areas typically perform identically with standard finishes, allowing you to allocate finishing budget where it provides real value.

Apply specific Ra callouts only to functional surfaces – sealing grooves, sliding interfaces, and customer-facing areas. Use general tolerance notes for structural surfaces. This selective approach helps us optimize manufacturing efficiency while meeting your performance requirements.

Anodizing over standard machined surfaces often delivers better long-term appearance than polishing alone. We’ve found this approach provides uniform color and scratch resistance while avoiding the maintenance issues that polished surfaces develop over time.