When it comes to protecting aluminum surfaces, Type III anodizing stands out as a powerhouse in the metal finishing industry. This hard-coat anodizing process creates a surface that rivals the hardness of case-hardened steel, making it a crucial treatment for demanding industrial applications.

Type III anodizing significantly enhances the hardness of aluminum surfaces, achieving a hardness rating of 60 to 70 on the Rockwell C scale (approximately 850-1,000 Vickers). This represents a substantial increase from untreated aluminum, with coating thicknesses typically ranging from 8 to 25 micrometers.

But what makes Type III anodizing achieve such remarkable hardness levels? Let’s dive into the key factors that influence the hardness of Type III anodized surfaces and discover why industries from aerospace to marine applications rely on this robust coating process.

Table of Contents

How Hard is Type 3 Anodized Aluminum?

Ever wondered what makes Type III anodized aluminum tough enough for aerospace applications? The secret lies in its incredible hardness rating of 60 to 70 on the Rockwell C scale – a level that rivals case-hardened steel and leaves untreated aluminum in the dust. This isn’t just a minor improvement; it’s a complete transformation of the material’s surface properties.

When measuring exceptional hardness, the Rockwell C scale serves as our industry gold standard. Using a precision diamond cone indenter, this testing method reveals exactly how well your anodized surface resists deformation under specific loads. Think of it as putting your material through a strength test that simulates real-world conditions – and Type III anodizing passes with flying colors.

The numbers tell an even more impressive story. Beyond the Rockwell C measurements, Type III anodizing achieves an astounding 850 to 1,000 on the Vickers hardness scale. This remarkable transformation doesn’t happen by chance – it’s the result of a precisely controlled process. By orchestrating the perfect combination of bath temperature, voltage levels, and current density, we create a ceramic-like coating that essentially acts as armor for your aluminum components.

But how does Type III anodized aluminum stack up against other materials? Here’s an eye-opening comparison:

Material Rockwell C Hardness (HRC) Relative Durability

Type III Anodized Aluminum 60-70 Very High

Case-Hardened Steel 58-63 High

Untreated Aluminum ~54 Low

Mild Steel 10-30 Medium

Tool Steel 58-65 High

How Thick is a Type 3 Anodized Coating?

The typical thickness of Type III anodized coatings ranges from 8 to 25 micrometers, with precise measurements tailored to specific application requirements. This controlled thickness plays a crucial role in achieving optimal surface hardness.

What makes this thickness range particularly special is its direct relationship with coating hardness. The careful balance of process parameters – from electrical current to temperature control – allows us to achieve these precise measurements consistently. For engineers and designers, this means you can specify exactly how thick you need your coating based on your application’s wear requirements. Need a coating that can handle extreme abrasion? We can push toward the upper range of 25 micrometers. Looking for a balance between protection and dimensional tolerance? The lower range might be your sweet spot.

Here’s how Type III anodizing thickness compares to other common surface treatments

Surface Treatment Typical Thickness Range (μm) Base Material Penetration

Type III Anodizing 8-25 50% of total thickness

Standard Anodizing 5-18 33% of total thickness

Hard Chrome Plating 2.5-500 Surface build-up only

Electroless Nickel 2.5-50 Surface build-up only

What Factors Affect the Hardness of Type 3 Anodizing?

The hardness of Type III anodizing is determined by three key factors: electrolyte composition, bath temperature, and voltage parameters, all working together to achieve those impressive 60-70 Rockwell C hardness ratings.

The electrolyte composition sets the foundation. With a carefully controlled sulfuric acid concentration of 15-20%, the anodizing bath creates the perfect environment for forming dense, hard coatings. Think of it as creating the ideal conditions for your aluminum surface to transform into its toughest possible state.

Temperature plays a surprisingly crucial role – Type III anodizing thrives in the cold. Operating at near-freezing temperatures (-4°C to 4°C) might seem extreme, but these low temperatures are essential for developing maximum hardness. Unlike standard anodizing, colder conditions help create a denser, more durable coating.

Here’s a quick look at how these key parameters affect coating hardness:

Parameter Range Impact on Hardness

Bath Temperature -4°C to 4°C Colder = Harder

Current Density 2-4 A/dm² Higher = Harder

Voltage 40-100V Higher = Thicker & Harder

Electrolyte 15-20% Optimal for max hardness

When these factors work in perfect harmony, they create the exceptional hardness that makes Type III anodizing the go-to choice for demanding applications. It’s all about precision and control – get these parameters right, and you’ll achieve that sought-after ceramic-like surface hardness.

Does Type 3 Anodizing Improve Wear Resistance?

Yes, Type III anodizing dramatically improves wear resistance, making treated surfaces up to 500 times more wear-resistant than untreated aluminum – a game-changing improvement for components facing harsh conditions.

This exceptional wear resistance comes from the unique structure of Type III anodized coating. As the hard oxide layer forms, it creates a surface that’s not just tough, but also incredibly resistant to abrasion and wear. For engineers and designers, this means components can handle continuous friction, repeated impacts, and constant wear without losing their protective properties.

Think about the practical implications: components that used to wear out in months can now last for years. The increased surface strength doesn’t just protect against normal wear and tear – it provides comprehensive protection against:

- Continuous sliding contact

- Repetitive impact

- Surface abrasion

- Particle erosion

Here’s how Type III anodizing stacks up against other surface treatments in wear resistance:

Surface Treatment Relative Wear Resistance Typical Applications

Type III Anodizing 500x base aluminum Heavy-duty machinery

Standard Anodizing 50x base aluminum Light-duty parts

Hard Chrome 200x base steel Automotive components

Untreated Aluminum Baseline Non-critical parts

This enhanced wear resistance, combined with its hardness properties, makes Type III anodizing an ideal choice for applications where component longevity is crucial.

What Industries Benefit from Type 3 Anodizing?

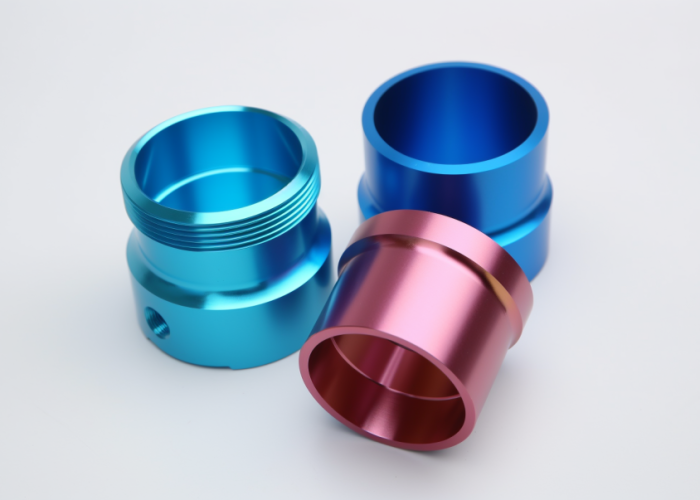

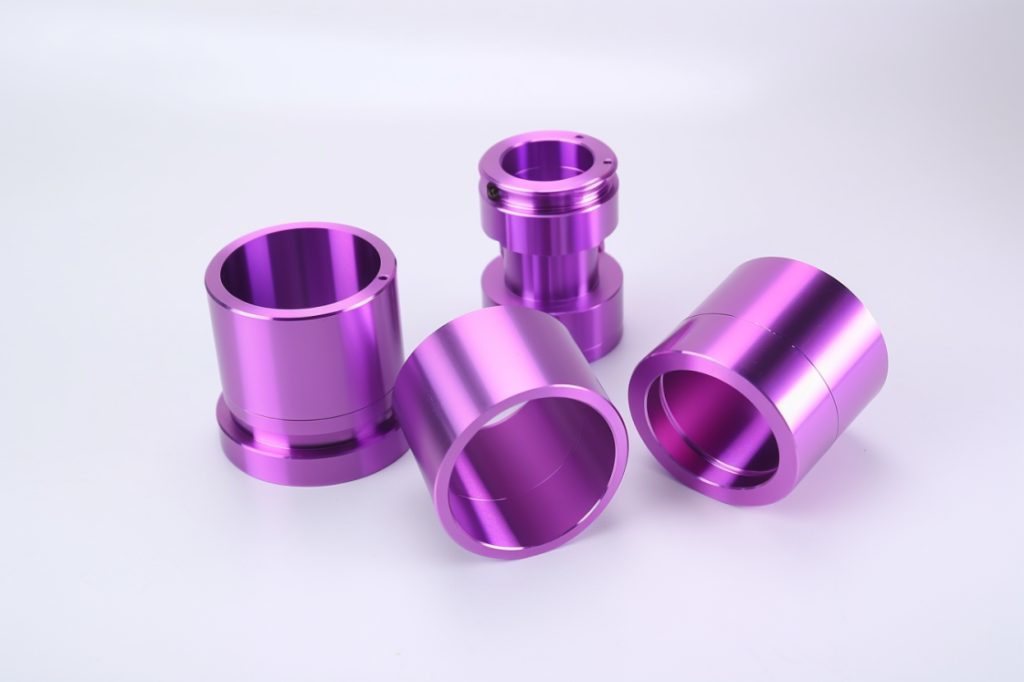

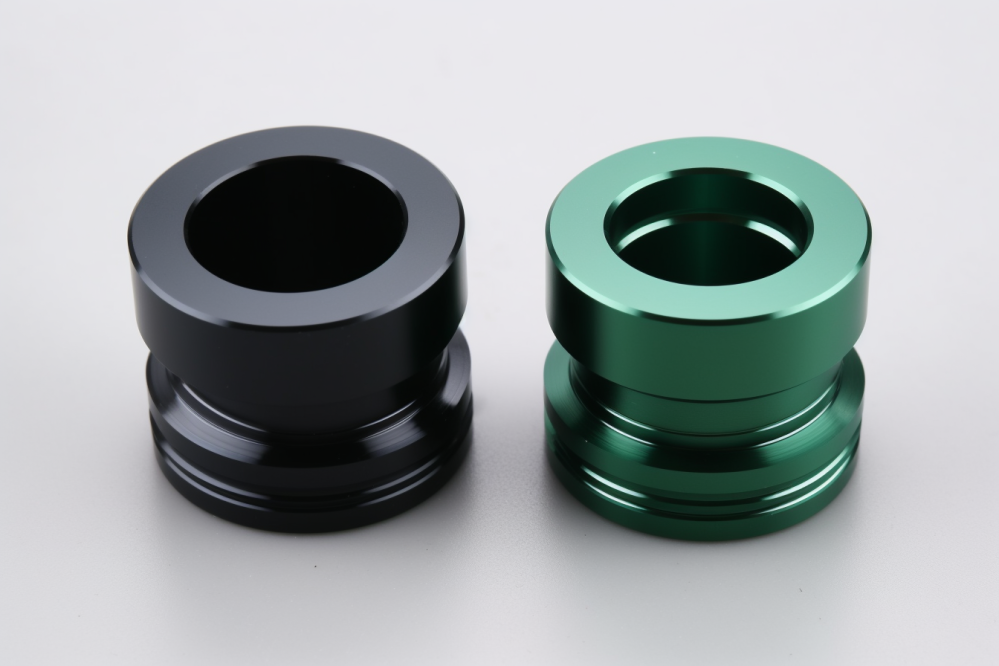

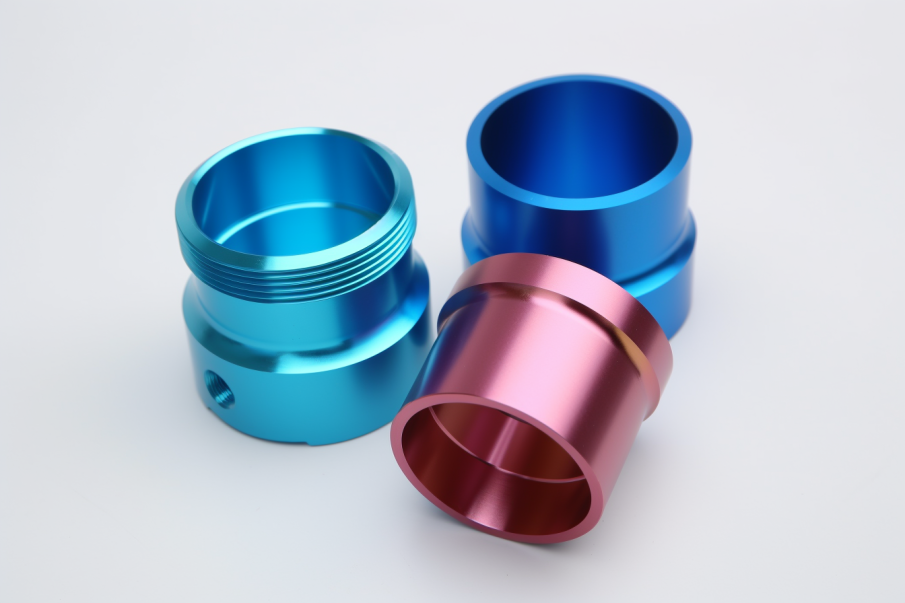

Type III anodizing finds its home in industries where durability and performance are non-negotiable. From aerospace to marine applications, this surface treatment has become essential for components that face extreme conditions.

The aerospace industry leads the charge in Type III anodizing adoption. Landing gear components and engine mounts rely on this treatment to handle intense mechanical stress and wear. Think about aircraft components that need to perform flawlessly thousands of feet in the air – that’s where Type III anodizing proves its worth

Industrial machinery comes next, where durability meets precision:

- Pistons and gears in heavy machinery

- High-speed manufacturing equipment

- Precision measurement tools

- Material handling components

Here’s how different industries leverage Type III anodizing:

Industry Common Applications Key Benefits

Aerospace Landing gear, engine parts High wear resistance, lightweight

Automotive Racing components, brake parts Durability, heat resistance

Industrial Pistons, gears, tooling Long service life, precision

Marine Propeller parts, deck hardware Corrosion resistance, strength

What makes Type III anodizing particularly valuable across these sectors isn’t just its hardness – it’s the combination of wear resistance, corrosion protection, and long-term reliability that keeps engineers coming back to this tried-and-true surface treatment.

Conclusion

Type III anodizing stands as a powerhouse surface treatment, delivering exceptional hardness (60-70 Rockwell C) and superior wear resistance that outperforms even hardened steel. From aerospace components to marine applications, this versatile process provides the durability modern engineering demands.

For projects requiring extreme surface hardness, precision wear resistance, and long-term reliability, Type III anodizing offers a proven solution. Whether you’re designing aerospace components or industrial machinery, consider Type III anodizing for your next high-performance application. Contact our specialists to explore how this exceptional surface treatment can enhance your components’ durability.

Frequently Asked Questions

The hardness of Type III anodized coating is permanent and will not deteriorate over time under normal operating conditions, lasting the entire lifetime of the component.

No, when properly processed, Type III anodizing produces uniform hardness across the entire treated surface, ensuring consistent wear protection.

Type III anodized aluminum is comparable to case-hardened steel (58-63 HRC) and significantly harder than untreated aluminum (~54 HRC).

Type III anodized aluminum has a hardness rating of 60-70 on the Rockwell C scale, or approximately 850-1,000 on the Vickers scale.

The optimal thickness for maximum hardness in Type III anodizing ranges from 8 to 25 micrometers, with thicker coatings generally providing better wear resistance.

No, the maximum hardness achievable with Type III anodizing is capped at approximately 70 HRC. Any claims of higher hardness values are not supported by industry standards and testing.