Hey there! If you’ve ever wondered about the superhero of the steel world that stands strong in the face of corrosion and wear, let me introduce you to surgical steel. This blog post is all about the wonders of this material and its pivotal role in custom part manufacturing. So, buckle up as we dive deep into the world where strength meets precision.

Table of Contents

What is special about surgical steel?

Surgical steel is a marvel in metals, boasting properties that make it indispensable in critical applications. Its claim to fame is its remarkable corrosion resistance and hypoallergenic nature, making it a hero in the medical industry.

But what truly sets surgical steel apart is its meticulous composition—a blend that includes chromium, nickel, and sometimes molybdenum, giving it an edge in durability and biocompatibility.

Composition and Properties of Surgical Steels

Surgical Steel Grades Explained

Surgical steel, a term often synonymous with medical-grade stainless steel, encompasses various grades, each with its unique composition and properties. Here’s a closer look:

– 316 and 316L Stainless Steel: These members of the austenitic stainless steel family are the stars of the surgical world. The “L” in 316L signifies a low carbon content, enhancing its corrosion resistance properties and making it ideal for medical applications, from surgical instruments to stainless steel tubing.

– 440C Stainless Steel: Recognized for its high strength and featured prominently in medical grade stainless steels, 440C offers excellent hardness after heat treatment, suitable for dental and surgical instruments that demand sharp precision.

– 420 Stainless Steel: This high carbon steel alloy is less resistant to corrosion but is popular in the medical industry for its strength and edge retention, essential for certain surgical tools that require a durable, sharp edge.

– 17-4 PH Stainless Steel: This less common yet versatile, precipitation-hardening steel alloy is noteworthy for its high strength and corrosion resistance, suitable for complex biomedical applications.

Mechanical Integrity and Corrosion Resistance

Surgical steels, particularly medical grade stainless steels like 316L, are engineered for their mechanical durability and corrosion-resistant nature. These steel alloys, including the low carbon variants, are designed to withstand the demanding conditions of the medical field, ensuring safety and longevity, whether they’re used in orthopedic implants or as part of the chemical composition of surgical tools.

Design Considerations for Surgical Steel

Designing with Surgical Steel

When it comes to designing with surgical steel, consider the medical grade of the alloy. For instance, 316L stainless steel, with its stable oxide bond and low carbon content, is a go-to for chemically inert medical instruments and sensitive applications like orthopedic implants. Its corrosion resistance properties are unmatched, ensuring the medical stainless steel remains free from rust and oxidation.

Surface Finishes: More Than Aesthetic

The surface finish on surgical stainless steel isn’t just for show; it’s a critical factor in medical applications. A smooth, non-magnetic finish minimizes the risk of crevice corrosion and inhibits bacterial growth, which is crucial for patient safety and hygiene in healthcare applications. Moreover, the right finish on surgical tools and medical instruments can significantly enhance the material’s corrosion resistance, ensuring durability and consistent performance in the demanding medical industry.

Manufacturing Techniques for Surgical Steel

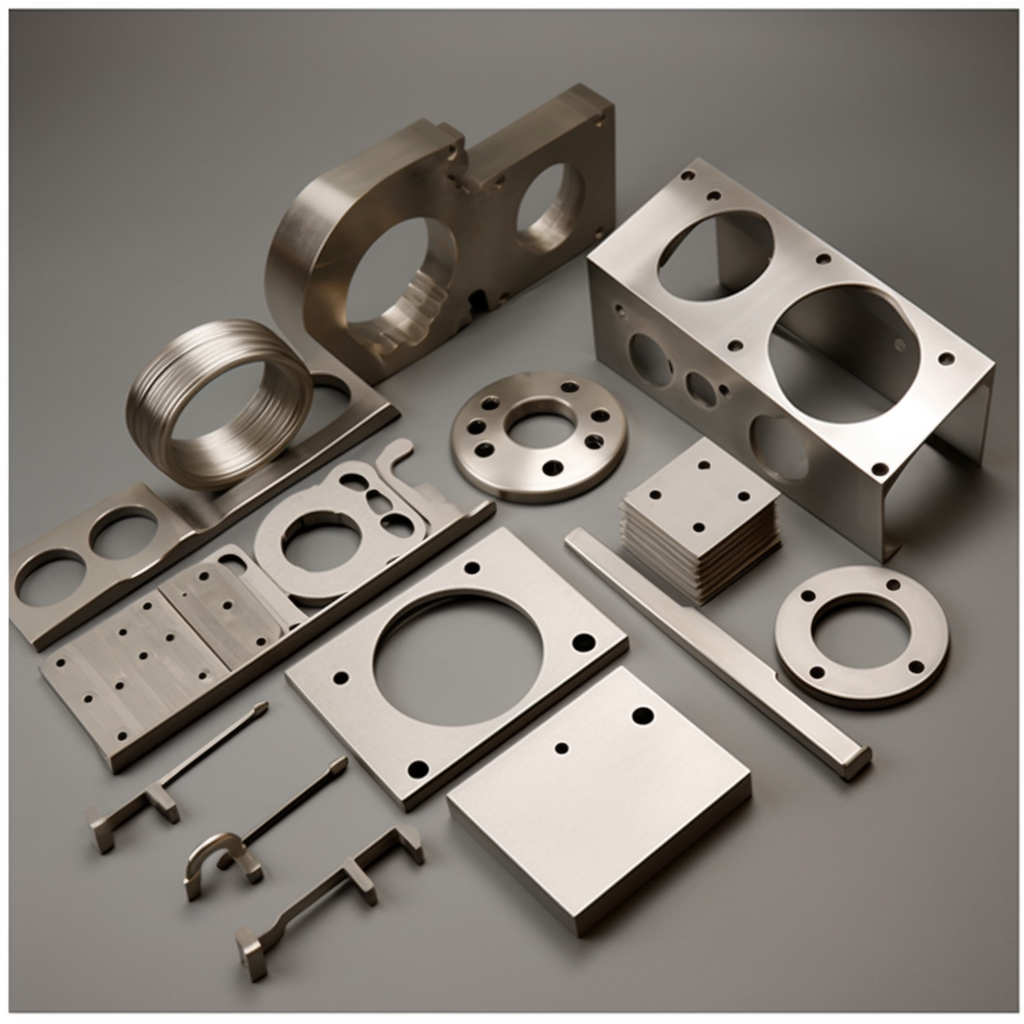

CNC Machining

CNC machining transforms surgical stainless steel into intricate medical instruments and components. This process takes advantage of the steel’s low carbon content and the austenitic stainless steel family’s renowned durability. The result? High-grade stainless steel surgical tools tailored for the medical field, from stainless steel tubing to complex dental instruments.

Stamping

Stamping surgical stainless steel yields high volumes of medical components, leveraging the material’s resistance to corrosion and its ability to withstand the rigors of the medical industry. The process respects the chemical composition of the steel, ensuring that the medical-grade steels, including those with high concentrations of nickel and molybdenum, maintain their integrity for sensitive applications.

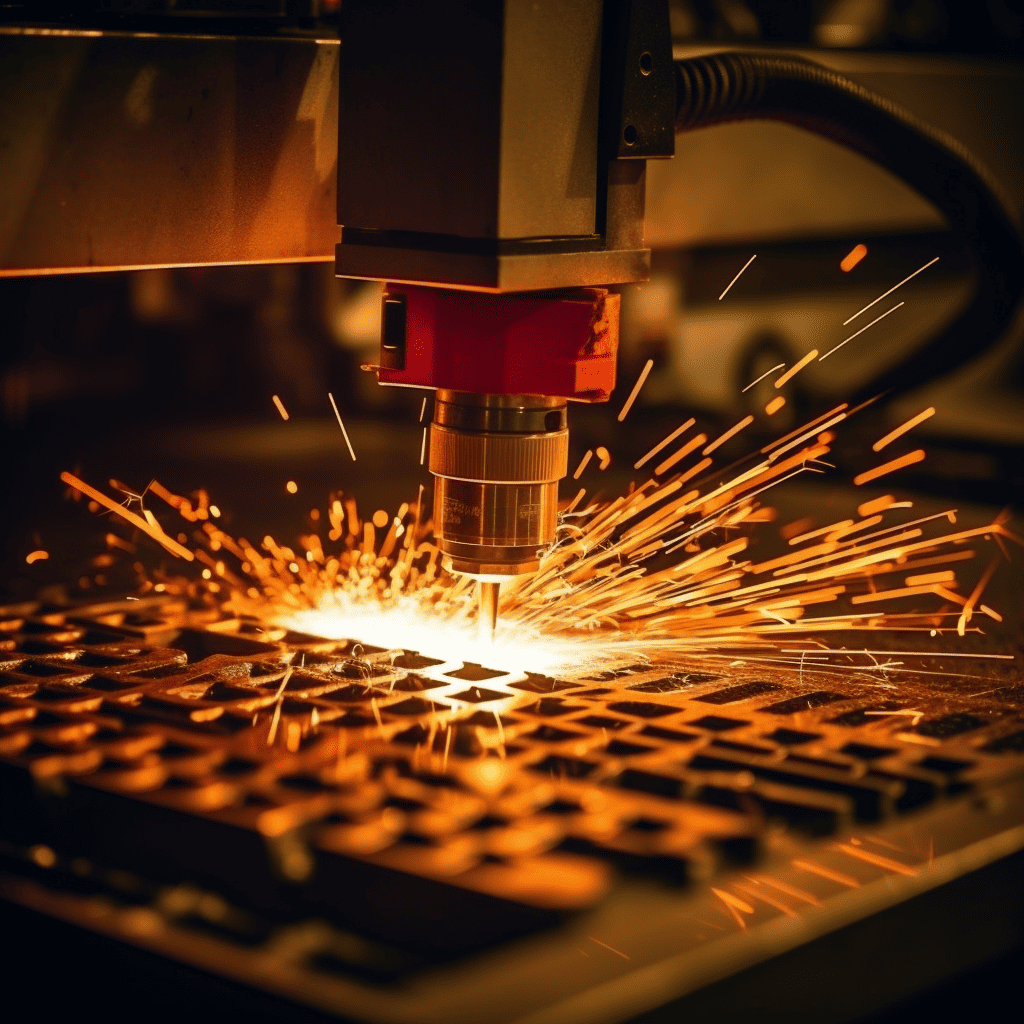

Laser Cutting and Welding

Laser-cutting surgical stainless steel offers a high degree of precision, essential for creating detailed components like dental instruments and implants for sensitive skin. Welding, while maintaining the corrosion resistance crucial to medical applications, requires a deep understanding of the steel’s base metal properties, including its chromium content and the formation of its stable oxide layer to prevent further oxidation.

Adapting to Various Medical Needs

Whether it’s through cold working or other forms of manipulation, surgical stainless steel’s adaptability to different manufacturing techniques like CNC machining and stamping makes it a cornerstone in producing durable, corrosion-resistant, and high-quality surgical tools and medical devices. Its long history in the medical industry is a testament to its reliable performance and the trust it has earned as a material that meets the stringent SAE EN standards for medical use.

Strategies for Efficient Manufacturing with Surgical Steel

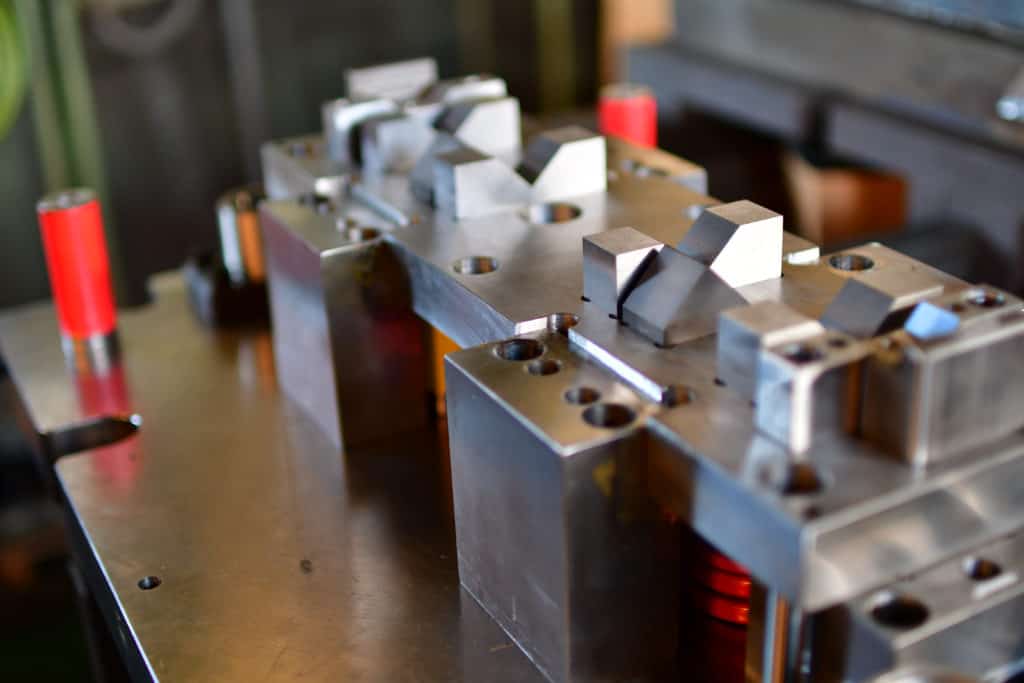

Tooling Considerations for Surgical Alloys

The choice of tool material is pivotal when machining medical-grade stainless steel. Tools with titanium or molybdenum coatings can withstand the rigors of machining corrosion-resistant alloys like 440C and 17-4 PH stainless steel. These coatings help maintain the metal’s surface finish, which is crucial for surgical tools that come into contact with the patient’s body, ensuring biocompatibility and resistance to bacterial colonization.

Advanced Cooling Systems for Heat-Treated Surgical Steels

Heat-treated surgical steels, known for their high strength and durability, necessitate advanced cooling techniques. High-pressure coolant systems not only manage thermal stress but also aid in maintaining the steel’s low carbon content and stable oxide layer, which is essential for preventing rust and ensuring the longevity of surgical instruments and dental implants.

Maintenance Protocols for Consistent Surgical Steel Quality

Regular maintenance is essential to uphold the quality of surgical steel components. This involves periodic checks and calibrations of CNC machines and tooling to prevent the introduction of free iron or carbon particles that could compromise the corrosion resistance properties of the steel, especially in grades like 316L and 440C, which are common in biomedical applications.

Customized Tooling for Diverse Surgical Steel Grades

It may be necessary to create custom tools to address the specific machining needs of different surgical steel grades. For instance, 420 stainless steel, known for its excellent formability and resistance to oxidation, might require different tool geometries compared to the more chromium-rich 316L or the martensitic 440C. Custom tooling ensures that each steel type’s unique properties, such as resistance to corrosion and wear, are preserved during the manufacturing process.

Quality Assurance and Regulatory Standards

Quality Assurance

When crafting surgical instruments and other medical applications, the integrity of medical-grade stainless steel is paramount. Here’s a closer look at the rigorous quality control measures in place:

1. Visual and Material Inspection

– Each stainless steel part is visually inspected to identify any surface imperfections. This step is crucial, especially for surgical instruments made from austenitic stainless steel family alloys known for their corrosion resistance and durability.

2. Dimensional and Composition Verification

– Using advanced measuring tools, the dimensions of each part are verified. Additionally, the chemical composition is analyzed to ensure the presence of key elements like chromium, nickel, and molybdenum, which contribute to the corrosion-resistant and durable nature of medical-grade stainless steel.

3. Surface Finish and Hardness Testing

– The surface finish of stainless steel is measured to confirm compliance with medical standards, ensuring that the low-carbon steel used does not become a breeding ground for bacteria. Hardness testing helps to verify that the steel, often an alloy of iron, carbon, and other metals, has been heat-treated correctly for optimal performance.

4. Passivation and Cleanliness Verification

– Passivation tests are essential to confirm that the stainless steel surface is free of iron and other contaminants, enhancing its corrosion-resistant properties. The cleanliness of each part is also verified, a critical step for items like surgical steel tubing, where internal cleanliness is as important as external.

ASTM and ISO Standards

Surgical steel parts must meet stringent standards to be deemed fit for medical use. Here are some of the benchmarks they are held against:

– ASTM F138 and F139:

– These standards govern the requirements for stainless steel, ensuring that medical grade steels like 316L or the durable 440C are used for surgical implants.

– ISO 5832-1:

– This standard provides a formal definition and testing methods for the austenitic stainless steel family, ensuring that the major elements responsible for corrosion resistance and strength, such as chromium and nickel, are in the right concentrations.

– ASTM A967 and AMS 2700:

– These documents detail the passivation process for stainless steel, a key step in manufacturing corrosion-resistant surgical instruments and ensuring that the metal’s surface is not a breeding ground for bacteria.

Surgical Steel in Medical Applications

Surgical steel isn’t just a material; it’s a cornerstone of modern medical technology. Here’s a closer look at where it makes a difference:

- Orthopedic Implants: 316L stainless steel is often used for joint replacements and bone-fixing hardware due to its strength and biocompatibility, ensuring that the implants remain durable and non-reactive inside the body.

- Surgical Instruments: The high chromium and low carbon content in surgical steels like 420 and 440C provide corrosion resistance for instruments such as scalpels, forceps, and clamps, subject to rigorous sterilization processes.

- Dental Tools and Implants: Dental drills, implants, and other instruments benefit from the corrosion-resistant and non-magnetic properties of surgical stainless steel, ensuring patient safety and tool longevity.

- Cardiovascular Devices: Devices like stents and pacemaker cases are often made from 316L stainless steel due to their excellent formability and resistance to blood and bodily fluids, reducing the risk of infection and rejection.

- Surgical Tubing: Stainless steel tubing, especially from the 316 series, is used for catheters and other fluid delivery systems because of its cleanability and resistance to corrosion, ensuring that no contaminants migrate during medical procedures.

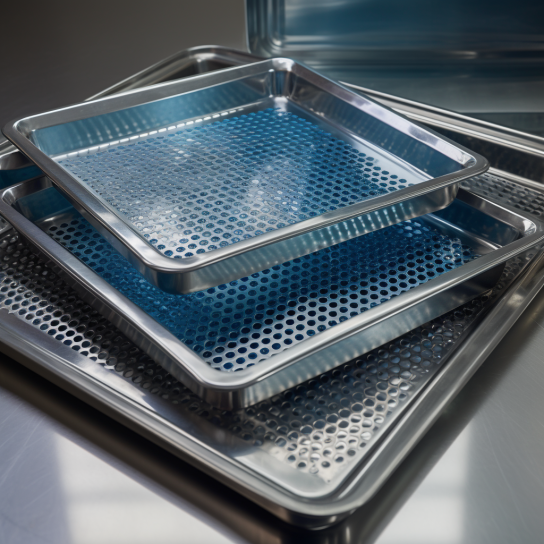

- Sterilization Trays: The high-temperature resistance and ability to withstand repeated cleaning make surgical stainless steel ideal for trays and containers used in autoclaves for sterilizing medical tools.

- Prosthetic Devices: Prosthetics require materials that are strong yet lightweight, and certain grades of surgical steel provide this balance, making them suitable for artificial limbs and joints.

Cost and Logistics Considerations

Understanding the Costs

When it comes to producing surgical steel parts, several key factors affect the bottom line:

- Material Choice: Opting for high-grade alloys like 316 stainless steel, known for its corrosion resistance and biocompatibility, can drive up costs due to the premium materials involved.

- Design Complexity: Detailed designs necessitate precise manufacturing techniques, which can increase production expenses.

- Order Volume: Bulk orders typically mean lower costs per unit, while custom or small batches may cost more.

- Manufacturing Efficiency: Efficient use of CNC machining and stamping for surgical steel impacts overall costs by reducing waste and tool wear

Lead Times and Shipping

Quick turnaround and reliable delivery are crucial in medical manufacturing:

1. Fast Lead Times: okdor offers rapid production, with CNC parts ready in 48 hours and sheet metal parts in 24 hours, catering to urgent demands.

2. Efficient Shipping: okdor handles shipping logistics to ensure fast and safe delivery of all surgical steel components, from titanium alloys to carbon steel parts.

By streamlining these aspects, okdor delivers high-quality surgical steel parts swiftly and efficiently, ensuring clients receive their orders on time and to specification.

Selecting a Manufacturing Partner

Selecting a partner skilled in handling stainless steels, especially those suitable for medical use, is critical. Okdor’s expertise in stainless steel and titanium alloys ensures that every component performs precisely and carefully. Here’s what sets Okdor apart:

Proven Precision and Expertise:

A manufacturer must understand the nuances of different steel types, including austenitic stainless steels and their grades. Okdor’s expertise in working with these metals, including the popular 316 stainless steel, positions them as a leader in the field.

Why Okdor Stands Out:

Okdor’s capabilities in CNC machining and stamping cater to the unique properties of surgical steel, ensuring that the final products are not only resistant to oxidation and corrosion but also meet stringent medical-grade standards.

Conclusion

The Indispensable Role of Surgical Steel

Surgical steel alloys, especially those within the 316 and 440 families, have become synonymous with strength and reliability in healthcare applications. Their excellent formability and resistance to crevice corrosion make them indispensable in the medical industry.

Your Project, Our Expertise

okdor’s commitment to quality and precision in manufacturing surgical steel parts is unwavering. With a deep understanding of the material’s properties, from its stable oxide bond to its resistance to further oxidation, we stands ready to meet the most demanding medical applications.

Embarking on a project that requires the highest grade of surgical steel? Contact Okdor at sales@okdor.com for expert guidance and a commitment to excellence in every part produced.

Frequently Asked Questions

Surgical steel, especially the medical-grade kind, suits skin contact in medical settings well. It resists corrosion and releases minimal nickel ions, making it hypoallergenic. However, people with nickel allergies should consider nickel-free options like BioDur® 108.

Surgical steel stands out for its excellent corrosion resistance, which surpasses regular stainless steel. Its chromium and molybdenum content ensures durability, making it the go-to material for surgical instruments and medical devices.

Surgical stainless steel is a type of stainless steel that offers better corrosion resistance and biocompatibility, fitting for making surgical instruments and implants.

Yes, surgical steel and regular stainless steel differ. Surgical grades meet the high standards for biocompatibility and corrosion resistance necessary for medical use, unlike regular stainless steel.

No, Surgical steel and titanium are different; titanium offers high strength and biocompatibility, while surgical stainless steel is more common for non-implantable surgical tools due to its excellent corrosion resistance.

Not all stainless steel can qualify as surgical steel. Surgical steel is a specific type of stainless steel tailored to meet the strict requirements of medical applications.

Medical-grade stainless steel is safe for a wide range of medical uses. Its inert nature and resistance to corrosion make it unlikely to react with body tissues.

316L stainless steel is often the best choice for medical use because of its superior corrosion resistance and lower nickel ion release, making it ideal for surgical and medical applications.

316 surgical steel is well-regarded in the medical community for its corrosion resistance and chromium content, making it suitable for surgical instruments and implants.

Surgical steel resists rust effectively due to its high chromium content, maintaining its integrity and appearance in the demanding medical environment.

Surgical stainless steel is less likely to tarnish thanks to its high-grade mix, which includes elements like chromium and molybdenum that enhance its corrosion resistance, ensuring reliability for medical uses.