Table of Contents

Brief Overview of Welding Types

There are three primary types of welding:

- Gas Tungsten Arc Welding (GTAW)

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding (GMAW)

Other welding processes like

- Flux Cored Arc Welding (FCAW)

- Tungsten Inert Gas (TIG) Welding

- Metal Inert Gas (MIG) Welding Stick Welding

- Plasma Arc Welding (PAW)

By understanding the characteristics of each welding process and considering factors such as material type, thickness, and project requirements, you can select the most suitable method for your sheet metal project.

Main Types of Welding

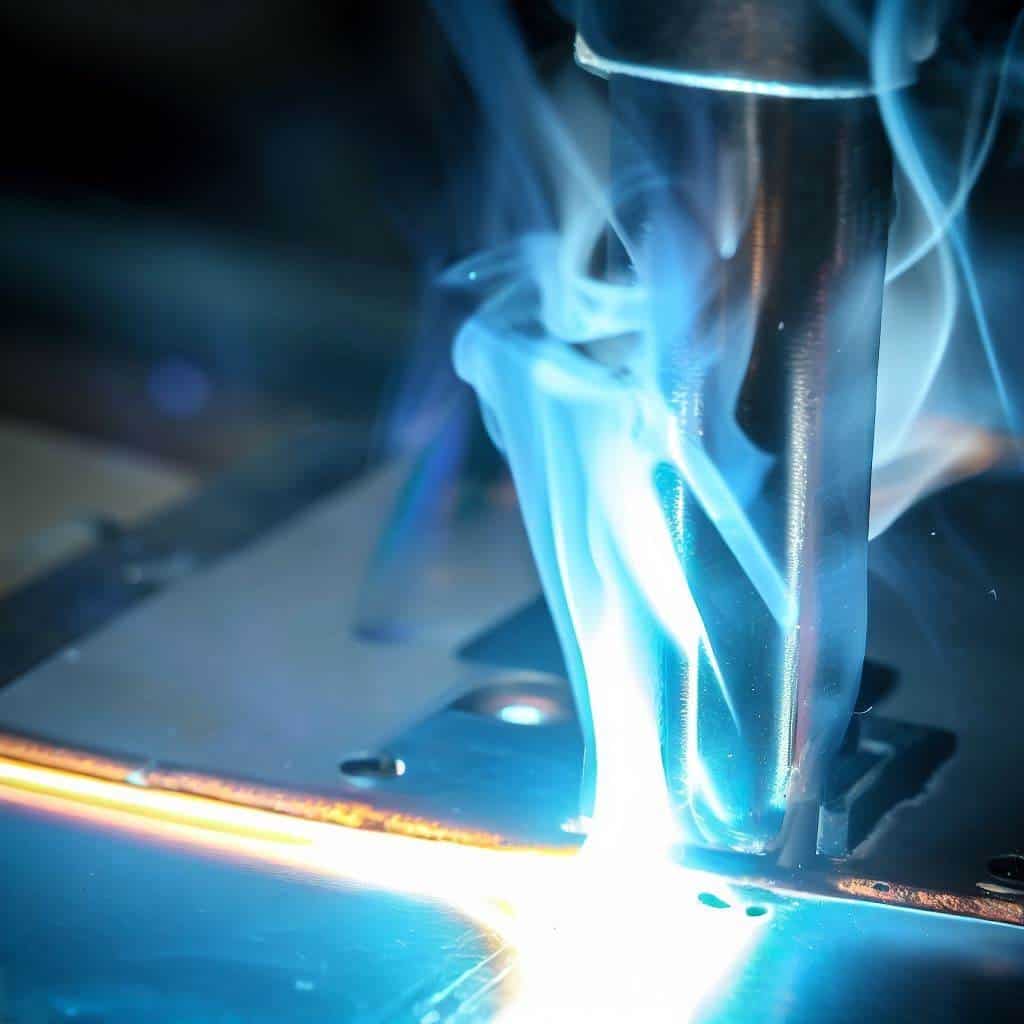

Gas Tungsten Arc Welding (GTAW)

Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW), is a versatile welding process that can produce high-quality welds. This method uses a non-consumable tungsten electrode to create heat and an externally supplied shielding gas, usually argon, to protect the weld pool.

GTAW is suitable for welding various materials, including stainless steel, aluminum, and copper alloys, and is ideal for joining thin materials and dissimilar metals.

One of the main advantages of GTAW is its ability to produce narrow welds with minimal distortion. This process can make strong welds, but it could be better for quickly making many welds. It is also more complex to do than other methods.

Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding (SMAW), commonly known as stick welding, is a popular and widely used process. It involves using a consumable electrode coated in flux to create heat and form a weld. The flux coating on the electrode generates a shielding gas, protecting the weld pool from contamination. This process suits various materials, including carbon steel, cast iron, and some stainless steel.

SMAW is known for its simplicity and portability, making it an excellent choice for field work and equipment repair. Suitable for use in various welding positions and effective on rusty or dirty materials. However, it generally produces more slag and spatter, which requires additional post-weld cleaning.

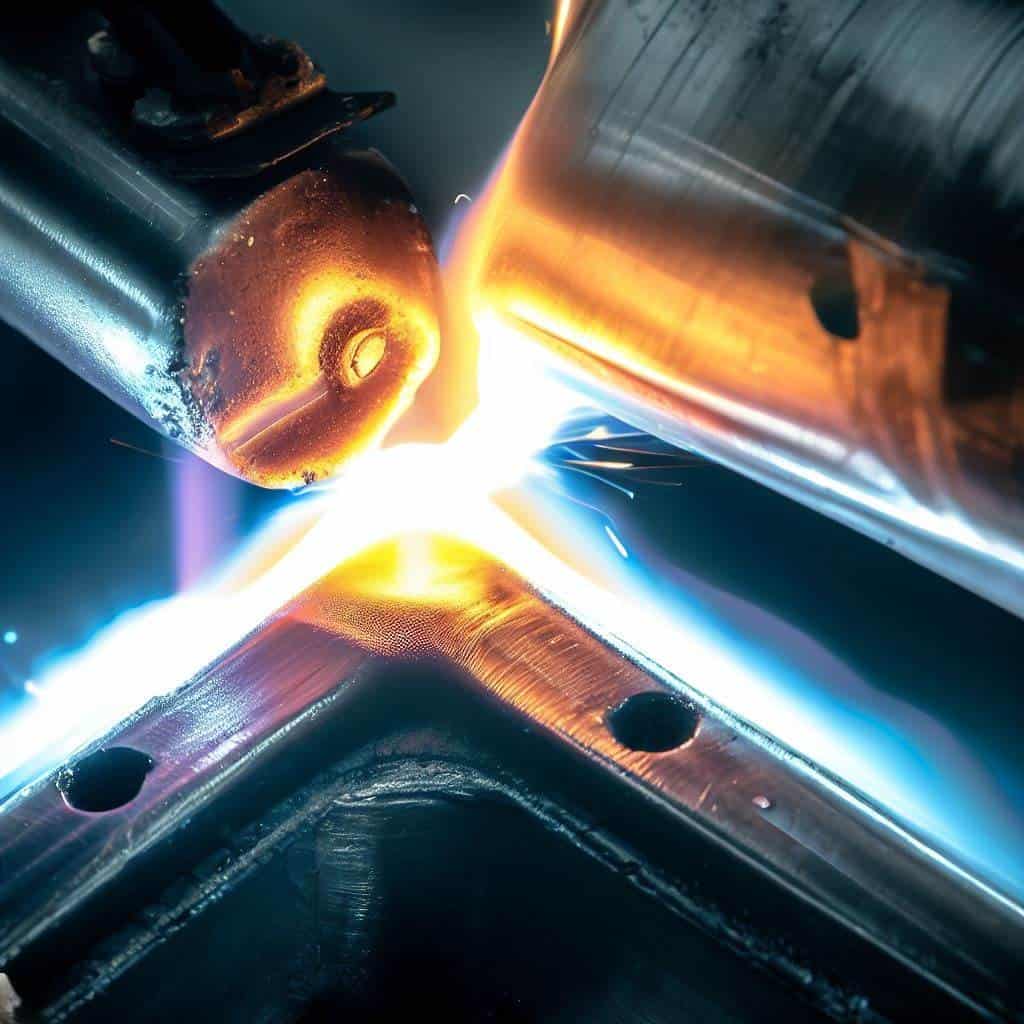

Gas Metal Arc Welding (GMAW)

Gas Metal Arc Welding (GMAW), or Metal Inert Gas (MIG) welding, is a typical industrial welding process that uses a consumable wire electrode and an externally supplied shielding gas, primarily carbon dioxide, to protect the weld pool. GMAW is suitable for many materials, including mild steel, stainless steel, and aluminum.

GMAW has the advantage of welding at high speeds, making it ideal for sheet metal fabrication and large-scale manufacturing. This process produces less slag and spatter than SMAW, reducing post-weld cleaning time.

However, GMAW is generally less effective on thick metals and may only be suitable for welding in some positions.

Other Common Welding Processes

Flux Cored Arc Welding (FCAW)

Flux Cored Arc Welding (FCAW) is a Gas Metal Arc Welding (GMAW) variation that uses a flux-cored wire instead of a solid wire electrode. The flux core provides the necessary shielding gas, eliminating the need for external gas sources.

FCAW is particularly useful for welding thick metals, as it can penetrate deeper and join metals faster than other processes. It’s also compelling for welding on rusty or dirty materials in various positions.

MIG Welding

Metal Inert Gas (MIG) Welding is another term for Gas Metal Arc Welding (GMAW), which we covered previously. The MIG welding process is a famous industrial method due to its high welding speed, the wide range of materials it can weld, and reduced post-weld cleaning time compared to other methods like SMAW.

Stick Welding

Stick Welding refers to Shielded Metal Arc Welding (SMAW), which we examined earlier. This process is known for its simplicity, portability, and effectiveness in various positions and on rusty or dirty materials.

Plasma Arc Welding (PAW)

Plasma Arc Welding (PAW) is a process that utilizes a constricted electric arc to create heat for welding. This method is similar to GTAW but operates at higher temperatures, allowing for narrower welds and faster welding speeds. PAW is suitable for joining thin materials and is popular in the aerospace and electronics industries.

Atomic Hydrogen Welding (AHW)

An electric arc is used between two tungsten electrodes to dissociate hydrogen gas into atomic hydrogen during Atomic Hydrogen Welding (AHW). The recombination of atomic hydrogen generates substantial heat to melt the base metal and form the weld. AHW is primarily used for welding high-melting-point metals and is rarely seen in everyday welding applications.

Laser Welding

Laser Welding is a modern welding process that uses a focused laser beam to create heat and join metals. This method is known for its precision, high welding speeds, and ability to weld thin materials with minimal heat distortion.

Laser welding is standard in the automotive, aerospace, electronics, and medical device manufacturing industries. However, it requires specialized equipment and is generally more expensive than other welding processes.

Welding Process Factors to Consider

Material Type

Choosing the appropriate welding process largely depends on the material you are dealing with. Certain welding methods are better suited for specific materials. For example, GTAW fits stainless steel, aluminum, and copper alloys, while SMAW is ideal for carbon steel and cast iron. Understanding the compatibility of welding processes with your material ensures strong welds and efficient use of resources.

Material Thickness

The thickness of the metals you plan to weld is another crucial consideration when choosing a welding process. Some methods, such as GTAW, are more suitable for thin materials due to their precision and ability to produce narrow welds. In contrast, FCAW is an excellent choice to weld thicker metals, as it can penetrate deeper and join metals faster than other processes.

Welding Positions

Welding positions play a crucial role in determining the appropriate welding method. Some processes, like SMAW and FCAW, are versatile and can be used in various welding positions. However, GMAW may not be suitable for all situations, especially overhead or vertical welding, as the molten metal may drip or sag.

Speed and Quality Requirements

Your project’s speed and quality requirements will also influence your welding process. If you need high-quality welds with minimal distortion, GTAW might be the best choice. However, if you prioritize speed and have a high-volume production project, GMAW is an excellent option due to its fast welding speeds.

Equipment and Skill Level

Considering both the availability of equipment and the skill level of the welder is crucial when deciding. Some welding processes, like SMAW, require minimal equipment and are relatively easy to learn, making them suitable for beginners or fieldwork. In contrast, GTAW and laser welding require more specialized equipment and a higher skill level, which may only be ideal for some projects or welders.

Understanding the distinctive features of each welding process is crucial for making the right choice for your sheet metal project.

How to Choose the Right Welding Method

For guidance in choosing a welding method for your sheet metal fabrication project, use these steps:

- Assess material type: Determine the material you will weld (e.g., stainless steel, aluminum, carbon steel) and choose the appropriate method. For instance, use GTAW for aluminum and stainless steel and SMAW for carbon steel.

- Determine metal thickness: Evaluate the thickness of the metals you plan to weld. If you are working with thin materials, GTAW or PAW may be the best options due to their precision and narrow welds. For thicker metals, consider using FCAW for deeper penetration and faster joining.

- Consider welding positions: Consider the welding positions required for your project. Some processes, like SMAW and FCAW, can be used in various places, while GMAW may only be suitable for some situations, especially overhead or vertical ones.

- Evaluate speed and quality requirements: Determine your project’s speed and quality requirements. If you need high-quality welds with minimal distortion, GTAW might be the best choice. However, if you prioritize speed and have a high-volume production project, GMAW is an excellent option due to its fast pace.

- Assess equipment and skill level: Consider the equipment and skill level of the welder working on the project. Some welding processes, like SMAW, require minimal equipment and are relatively easy to learn. In contrast, GTAW and laser one require more specialized equipment and a higher skill level.

Following the outlined steps and considering the factors discussed in this article, you can choose the appropriate welding method for your sheet metal fabrication project. Remember that selecting the proper process will result in robust welds, exceptional work, and improved productivity, all contributing to a successful and economic project.

Conclusion

This article talks about different ways of welding. These include Gas Tungsten Arc Welding (GTAW), Shielded Metal Arc Welding (SMAW), and Gas Metal Arc Welding(GMAW). It also talks about Flux Cored Arc Welding (FCAW), Plasma Arc Welding (PAW), Atomic Hydrogen Welding (AHW), and Laser Welding.

We also discussed the factors to consider when choosing a welding method, including material type, the thickness of metals, welding positions, speed, quality requirements, and equipment and skill level.

Selecting the proper welding process for your sheet metal fabrication project ensures strong welds, high-quality work, and overall efficiency. After reading this article, you can decide which way is best for your project.

Think about what was discussed and choose the best option. The result will result in a successful project that is cost-effective and achieves optimal durability, performance, and appearance.

Frequently Asked Questions

Fuel gases, such as acetylene, propane, and natural gas, are used in gas welding processes, such as oxy-acetylene welding. These gases are mixed with oxygen and ignited to produce a flame that heats and melts the base metals, allowing them to join.

Although welding processes such as Shielded Metal Arc Welding (SMAW) and Flux Cored Arc Welding (FCAW) can work well when welding rusty or dirty materials, it’s still important to clean the material as thoroughly as possible to get the best outcome. For more information, don’t hesitate to contact us via sales@okdor.com.

Electron beam welding is a high-precision welding process that creates heat and joins metals using a focused beam of electrons. There is a lot of use for it in industries like aerospace and electronics.

MIG welders are versatile and can be used for various metals, such as mild steel, stainless steel, and aluminum. However, some metals may require specialized welding processes or techniques for optimal results.

Welding wire is a filler material used in processes like GMAW and FCAW. The wire is fed through a welding gun and melts into the weld pool to join the base metals.

The power supply provides the necessary electrical energy for welding. Different welding processes require different types of power supplies, and the stability and control of the power supply can significantly impact the quality of the weld.

Metal Inert Gas (MIG) welding is one of the most widely used industrial welding processes. This process is preferred because it offers high welding speeds and versatility and requires less time for post-weld cleaning.

Filler metal is a material added to the weld pool during arc welding to help join the base metals, strengthen the weld, and provide corrosion resistance.

Consumable electrodes serve as a filler material in the welding process, providing additional metal to help join the base metals and form a strong weld.