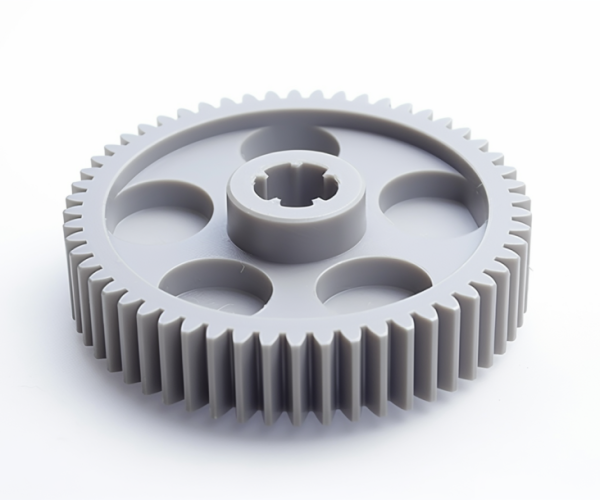

Selecting the right gear type can make or break your mechanical design — especially when balancing performance, cost, and manufacturability constraints. With decades of experience machining precision gears for robotics, automation, and industrial equipment, even seasoned engineers sometimes overlook how spur gear advantages align with specific application requirements.

Spur gears are the optimal choice for parallel shaft applications requiring cost-effective power transmission with moderate speed and noise requirements. They offer the simplest manufacturing setup, highest torque density per dollar, and most predictable performance characteristics of any gear type.

Learn when spur gears beat helical or planetary types, how to manage speed and backlash limits, and how to design for cost and reliability in precision builds.

Table of Contents

When is a spur gear the best choice for motion transfer?

Spur gears are the optimal choice for parallel shaft applications where cost efficiency and straightforward power transmission outweigh noise considerations. Use spur gears when shafts are exactly parallel, operational speeds stay under 3,000 RPM, and noise levels up to 55-65 dB are acceptable. They deliver the lowest cost per unit of torque transmitted and require the simplest manufacturing specifications.

In our gear machining experience, spur gears work best for industrial automation, conveyor systems, and positioning equipment where reliable operation matters more than whisper-quiet performance. Spur gears cost 20-35% less than helical equivalents because they eliminate helix angle tolerances, reduce setup complexity, and use standard cutting tools readily available from any supplier.

Primary decision criteria for spur gear selection:

- Parallel shaft arrangement (±0.1° maximum misalignment)

- Moderate speed requirements (typically under 3,000 RPM)

- Acceptable noise levels in industrial environments

- Cost optimization priority over premium performance features

Immediate disqualifiers: Non-parallel shafts, high-speed applications above 4,000 RPM, or noise-sensitive environments requiring under 45 dB operation. For these scenarios, consider helical or planetary alternatives despite higher costs.

Design Takeaway: Start with spur gears for any parallel shaft application, then validate against specific speed limits, torque requirements, and noise constraints before upgrading to more complex gear types.

Why are spur gears considered the most cost-effective gear type?

Spur gears are the most cost-effective choice when budget constraints, tight timelines, or supplier availability drive your gear selection. They offer the widest supplier base, fastest delivery times, and most predictable pricing of any gear type. Choose spur gears when cost optimization takes priority over premium performance features like ultra-quiet operation or compact packaging.

From our specification experience, spur gears excel in three key cost scenarios: rapid prototyping where speed to market matters, budget-constrained projects where every dollar counts, and high-volume production where tooling simplicity reduces per-unit costs. The manufacturing simplicity means more suppliers can quote competitively, giving you leverage in procurement negotiations and backup options if delivery issues arise.

Decision framework for cost-driven scenarios:

- If delivery timeline is critical → spur gears offer faster supplier response and shorter lead times

- If you need multiple supplier quotes → spur gears provide more machining options for competitive bidding

- If gear cost significantly impacts total product cost → evaluate spur gears first before upgrading to complex types

- If this is prototype or low-volume production → spur gears reduce tooling complexity and setup costs

- If long-term replacement parts matter → spur gears use standard geometries with wide availability

The key advantage is specification simplicity – fewer tolerance callouts mean faster quoting, fewer manufacturing variables mean more predictable costs, and standard geometries mean readily available replacement parts. This translates to lower engineering overhead and reduced procurement complexity throughout the product lifecycle.

Design Takeaway: Default to spur gears when cost control, supplier flexibility, or delivery speed are primary concerns. Only specify more complex gear types when your application specifically requires their premium features and the budget supports the cost increase.

Are spur gears too loud for noise-sensitive applications?

Spur gears are unsuitable for applications where operational noise affects user experience, product perception, or equipment function. They work well in industrial environments where mechanical noise is expected, but avoid them in office equipment, medical devices, or consumer products where quiet operation is a competitive requirement or user expectation.

The application environment determines noise acceptability. Manufacturing floors, outdoor equipment, and industrial automation typically operate in environments where gear noise doesn’t impact functionality or user satisfaction. Office automation, laboratory instruments, and consumer products require quieter operation that justifies the cost premium for helical alternatives.

Decision framework for noise-sensitive evaluation:

- If your product operates in factory/industrial settings → spur gear noise typically acceptable within ambient sound levels

- If used in office or laboratory environments → consider noise impact on user concentration and equipment operation

- If your product already includes motors, fans, or pneumatic components → gear noise may be irrelevant to overall acoustic performance

- If quiet operation appears in your product requirements → avoid spur gears and budget for helical alternatives

- If competing products emphasize quiet operation → noise becomes a competitive factor requiring helical gears

- If your product is used in noise-sensitive environments (medical, precision measurement) → spur gears will likely fail user acceptance

Consider noise in context of total system design. The operational environment and user expectations matter more than absolute noise levels when making gear selection decisions.

Design Takeaway: Use spur gears when operational noise doesn’t conflict with user expectations, product requirements, or competitive positioning. Choose helical gears when quiet operation is specified, expected by users, or necessary for proper system function.

Can spur gears handle high torque loads reliably?

Spur gears handle high torque loads reliably and are typically the best choice for heavy-duty industrial applications where consistent power transmission is required. They excel in continuous-duty applications like conveyor drives, industrial mixers, and manufacturing equipment where steady torque loads are more important than quiet operation or compact packaging.

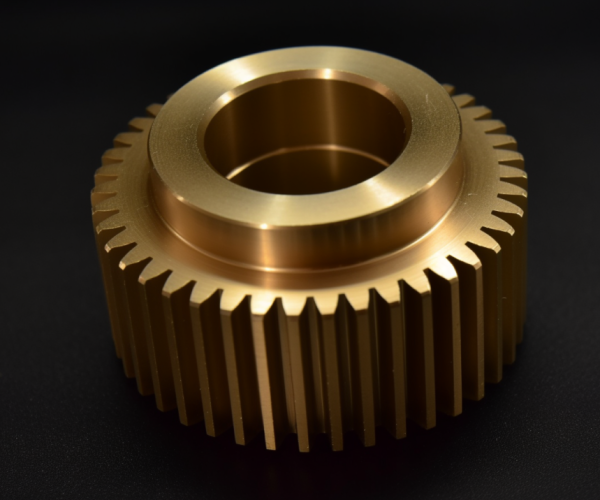

Engineering specifications show spur gears performing well in applications requiring substantial torque transmission. Material selection significantly impacts performance – steel spur gears handle considerably higher loads than aluminum alternatives while maintaining manufacturing simplicity and cost advantages over complex gear geometries.

Torque application decision criteria:

- If your application involves continuous, steady loads → spur gears provide reliable transmission without complex bearing requirements

- If shock loads or sudden torque spikes are minimal → straight tooth geometry handles predictable loads effectively

- If equipment operates in industrial environments → spur gears tolerate dust, vibration, and moderate misalignment better than precision gear types

- If maintenance intervals can accommodate standard lubrication → spur gears operate reliably with conventional maintenance practices

- If load direction remains consistent → spur gears’ radial force pattern simplifies housing and bearing design

Applications where spur gears excel include industrial automation, material handling systems, and manufacturing equipment where torque consistency matters more than noise levels. Their robust tooth geometry and straightforward load path make them suitable for demanding industrial environments.

Design Takeaway: Choose spur gears for high-torque industrial applications where reliable power transmission, maintenance simplicity, and cost control outweigh noise or space considerations. Reserve complex gear types for applications specifically requiring their premium features.

Want a simple, cost-effective gear design?

Spur gears are fast & affordable • We’ll review your tolerances + backlash

Do spur gears help reduce part cost or supplier lead time?

Spur gears deliver the shortest lead times because they require no specialized manufacturing equipment or custom tooling that other gear types demand. Standard gear cutting capabilities exist at most machine shops, eliminating the scheduling delays and tooling procurement that extend delivery times for helical or planetary gears. For urgent projects or compressed development schedules, spur gears offer the fastest path to manufactured parts.

Manufacturing scheduling advantages stem from widespread capability and standard tooling availability. Setup procedures are straightforward and quality inspection uses common measurement tools, reducing both manufacturing time and potential delays from specialized equipment availability or operator training requirements.

Timeline-driven decision criteria:

- If project delivery is time-critical → spur gears typically reduce lead times by eliminating specialized tooling procurement

- If prototype iterations are needed quickly → standard manufacturing processes enable faster design validation cycles

- If supplier capacity constraints exist → broader manufacturing base provides more scheduling options during peak periods

- If procurement team needs fast supplier response → standard specifications generate quicker quotes and delivery commitments

- If design changes may occur during development → spur gears accommodate modifications without custom tooling penalties

The delivery advantage extends beyond initial manufacturing to include design iteration speed and supplier flexibility during development phases. Standard geometries and widely available manufacturing capabilities eliminate bottlenecks that constrain project timelines.

Design Takeaway: Prioritize spur gears when delivery schedules drive gear selection decisions. The timeline advantages often justify accepting higher noise levels when development speed or market timing requirements are critical.

Are spur gears suitable for space-constrained designs?

Spur gears are unsuitable for compact designs and should be avoided when housing size, weight, or packaging constraints drive your design requirements. They require parallel shaft arrangements that create larger assemblies compared to planetary or helical alternatives designed for space efficiency. Choose spur gears only when adequate space is available and cost or manufacturing advantages outweigh size penalties.

Application-based space decision criteria:

- If your product must fit in handheld or portable packaging → spur gears typically eliminate design feasibility due to size requirements

- If automotive, medical device, or consumer electronics applications → compact packaging usually mandates planetary or other space-efficient gear types

- If stationary industrial equipment with dedicated machinery housing → spur gears work well when space isn’t a design constraint

- If maintenance access matters more than compact size → spur gears provide easier inspection and service compared to compact planetary systems

- If weight restrictions apply to your design → larger spur gear assemblies may violate weight budgets for portable or aerospace applications

The parallel shaft requirement creates additional packaging challenges when shafts must be positioned at angles or where complex gear arrangements are needed within limited envelope space. Industrial automation, manufacturing equipment, and stationary machinery typically provide adequate room for spur gear benefits, while portable devices, precision instruments, and automotive applications require more compact solutions.

Design Takeaway: Immediately eliminate spur gears from consideration if your application involves portable equipment, consumer products, or any design where housing size directly affects user experience or competitive positioning.

What's the maximum speed limit for spur gears?

Spur gears become problematic above moderate industrial speeds due to increased noise, vibration, and rough operation that affects system performance. They work reliably for typical manufacturing and automation speeds but should be avoided for high-speed applications where smooth operation or precision motion control are required.

Speed-based application decision criteria:

- If your application involves typical industrial automation or manufacturing equipment → spur gears handle these operating speeds effectively

- If your system requires high-speed spindles, precision instruments, or laboratory equipment → speed-related noise and vibration typically eliminate spur gears

- If automotive transmission or high-performance machinery applications → speed limitations usually mandate helical or other smooth-operating gear types

- If conveyor systems, packaging machinery, or material handling equipment → these applications typically operate within spur gear speed capabilities

- If noise increases would affect user acceptance or system accuracy → speed-related performance degradation eliminates spur gears regardless of cost advantages

Think in terms of application categories: factory equipment like conveyors and industrial mixers work well with spur gears, while drill presses, CNC spindles, and precision positioning systems typically require helical alternatives for smooth, quiet operation at higher speeds.

Design Takeaway: Choose spur gears for industrial equipment operating at typical production speeds. Avoid them when your application requires high-speed operation, precision motion control, or when speed-related noise would affect user experience or system performance.

How much backlash do spur gears typically have?

Spur gears have more backlash than precision applications can typically tolerate, making them problematic for positioning systems, frequent direction changes, or servo control applications. The backlash amount varies based on manufacturing tolerances and assembly precision, but is generally higher than what precision motion control requires. For applications requiring accurate positioning or frequent reversals, spur gear backlash often eliminates them from consideration.

Backlash sensitivity evaluation for your application:

- If your system requires precise positioning or repeatability → spur gear backlash will likely exceed acceptable error budgets

- If direction changes occur frequently during operation → backlash creates noticeable dead zones and response delays that affect performance

- If servo control or closed-loop positioning systems → backlash interferes with control accuracy and introduces lag

- If one-directional power transmission like conveyors or pumps → backlash rarely affects operational performance

- If your application resembles CNC machinery, robotics, or precision instruments → backlash typically eliminates spur gears from consideration

- If your application resembles industrial mixers, conveyor drives, or manufacturing equipment → backlash remains within acceptable operational limits

Manufacturing tolerances significantly affect backlash amounts. Standard commercial gears have higher backlash than precision-ground alternatives, but precision manufacturing increases costs substantially. Most engineers choose helical gears or anti-backlash mechanisms rather than upgrading spur gear precision when backlash matters.

Design Takeaway: Accept spur gear backlash for steady, unidirectional applications like industrial equipment. Choose alternatives when your application requires precision positioning, frequent direction changes, or when backlash would affect user experience or system accuracy.

When should I use spur gears instead of helical or planetary?

Choose spur gears when cost control, manufacturing simplicity, and supplier availability outweigh the premium features that helical or planetary gears provide. Spur gears excel in applications where straightforward power transmission, fast delivery, and competitive pricing matter more than quiet operation, compact packaging, or high-speed performance.

Spur vs helical decision criteria:

- If operational noise levels similar to industrial equipment are acceptable → spur gears provide cost savings without functional penalties

- If your operating speeds are similar to conveyor motors or manufacturing equipment → helical smoothness isn’t necessary

- If budget constraints or competitive pricing pressure exists → spur gears offer significant cost advantages for equivalent torque capacity

- If your application resembles office equipment, medical devices, or precision instruments → helical gears justify their cost premium for quiet operation

Spur vs planetary decision criteria:

- If your housing size is similar to industrial machinery rather than handheld devices → spur gears avoid planetary complexity and cost

- If gear ratios under 10:1 meet your requirements → spur gears provide simpler solutions than planetary alternatives

- If your application resembles automotive, aerospace, or compact consumer products → planetary systems become necessary despite higher costs

- If your mechanical layout allows parallel shafts rather than coaxial arrangement → spur gears often fit better and cost less

The key decision factor is whether your application specifically requires the premium features of helical or planetary gears. Most industrial power transmission applications perform adequately with spur gears at significantly lower cost and complexity.

Design Takeaway: Start with spur gears for any power transmission application, then upgrade only when your product category (medical, automotive, consumer electronics) or specific requirements (quiet operation, compact size) demand helical or planetary alternatives.

Conclusion

Spur gears deliver optimal cost-effectiveness for parallel shaft applications where noise and space aren’t critical constraints. They excel in industrial equipment requiring reliable torque transmission at competitive pricing. Choose helical or planetary alternatives only when your application specifically demands their premium features like quiet operation or compact packaging.

Contact us to explore spur gear manufacturing solutions tailored to your product requirements.

Frequently Asked Questions

Spur gears offer minimal cost difference between prototype and production due to standard tooling availability. Unlike complex gear types requiring custom tooling investments, spur gears maintain competitive pricing across volume ranges, ideal for rapid prototyping.

Spur gears perform well in demanding environments due to their robust tooth geometry and tolerance for moderate misalignment. They’re commonly used in outdoor equipment, dusty manufacturing, and applications with temperature variations. Their design simplifies maintenance compared to complex gear types.

Reference standard tooth profiles (AGMA or ISO specifications), specify functional tolerances only, and ensure adequate tool clearance. Avoid custom profiles or unnecessarily tight tolerances requiring specialized tooling. Standard specifications typically reduce lead times by 1-2 weeks.

Upgrade when noise levels affect user acceptance, high-speed operation creates vibration problems, or smooth motion is critical for accuracy. If your product operates in quiet environments or competes on acoustic performance, helical gears usually justify their cost premium.

Single-stage spur gear ratios typically stay under 10:1 for practical reasons. Beyond this, consider compound gear trains or evaluate whether planetary systems justify their complexity. Higher ratios often require larger assemblies that may conflict with space constraints.

Spur gears handle most industrial torque requirements effectively. If your application involves shock loads or torque levels similar to heavy construction equipment, steel spur gears typically handle substantially higher loads than aluminum alternatives while maintaining cost advantages over complex gear types.