Your parts are machined—but nowhere near shipping. Weeks pass after “CNC complete,” and updates turn vague. That’s not finishing; that’s a control failure.

Lead times explode after machining because suppliers lose control once parts leave their shop.Outsourced anodizing, missed masking prep, or waiting in third-party queues stretch days into weeks.

Read on to see how to spot these warning signs early—and how Okdor prevents them with in-house finishing control and 24-hour supplier updates.

Table of Contents

Is Your Supplier Finishing Your Parts—or Just Stalling?

If your supplier says “in finishing” but nothing ships for weeks, they’re waiting—not working.

That phrase often hides downtime while parts sit at a third-party finisher with no confirmed slot. Many shops outsource anodizing or coating and lose all visibility once the job leaves their floor. Each extra week compounds risk—testing windows slip, project milestones move, and your team loses credibility upstream.

Most machining suppliers depend on a single finisher. When that vendor delays, rejects batches for masking issues, or closes for maintenance, your order freezes mid-process. They won’t admit it because they can’t fix it. Vague updates like “next week” simply buy time until someone else replies.

We prevent that stall by integrating finishing control into production scheduling. Every project’s coating, masking, and inspection steps are pre-booked before machining starts, keeping parts flowing straight from mill to finishing line. Real-time tracking logs show when coating begins, ends, and passes inspection—so you never need to chase progress reports.

Why this matters: silence at this stage isn’t harmless—it’s the moment when you lose escalation leverage. Knowing where your parts truly are lets you intervene before deadlines collapse.

Supplier Takeaway:

If “in finishing” lasts longer than machining, you’re dealing with a queue, not progress. Ask who physically controls the coating line. Suppliers that schedule finishing as part of production—not after—are the ones that actually deliver on time.

How Much Longer Will This Actually Take?

Lead-time blowouts after machining add one to three weeks because suppliers can’t control outsourced finishing queues.

Once parts leave the machine shop, they wait behind larger customer batches, transport delays, or masking reworks. The supplier’s “should ship soon” isn’t an update—it’s an assumption. Those extra days cascade into missed testing rounds and stalled product launches.

The real cause isn’t process complexity; it’s scheduling blindness. When finishing isn’t locked into the quote plan, everything becomes reactive. Shops hope their preferred anodizer has capacity, but if not, your order idles off-site while no one can adjust the sequence. By the time you realize, it’s too late to reallocate or switch vendors.

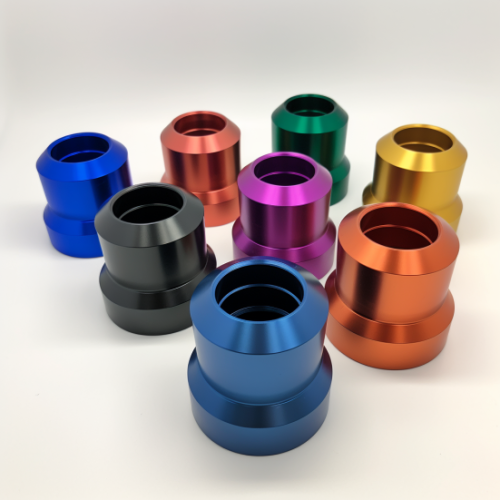

We schedule finishing windows before machining begins, confirming finish type, color, and masking requirements upfront. Every step—machining, coating, inspection, packaging—is timestamped in one workflow. If a delay appears, we re-sequence internally instead of waiting for news. That control keeps completion dates credible and communication constant.

Why this matters: without visibility, you can’t escalate or commit to your own customer. The longer uncertainty lasts, the more your production plan unravels.

Supplier Takeaway:

If your supplier can’t name the exact date finishing starts or ends, your project’s already adrift. Work with suppliers who integrate finishing capacity from the start—you’ll get firm ship dates and avoid the slow collapse of “almost done” timelines.

Why Can’t Your Supplier Give You a Real Ship Date?

If a supplier keeps revising your ship date, they don’t control the schedule—they’re reacting to it.

Most machining shops can predict cutting time precisely but ignore what happens after the last toolpath. Finishing, inspection, and packing depend on subcontractors, so the delivery date becomes a moving target.

Once parts leave the shop, they enter external queues. Each missed pickup or rejected batch shifts completion by several days. Suppliers try to appear organized by sending new ETAs, but those are guesses, not milestones. That’s why updates sound confident yet never match reality.

We calculate ship dates from an integrated schedule—machining, finishing, inspection, and packaging in one line of control. When a stage changes, the timeline adjusts instantly. In controlled workflows like this, on-time delivery accuracy improves from roughly 60 % industry average to above 95 % because finishing is planned, not outsourced blindly.

Why this matters: unreliable ship dates don’t just delay parts—they disrupt builds, downstream testing, and purchasing credibility. Predictability is more valuable than promises.

Supplier Takeaway:

If a supplier can’t explain how their ship date was calculated, they’re estimating, not managing. Ask for the complete schedule showing machining through packaging. Real suppliers forecast from controlled capacity, not guesswork.

Supplier delays mounting?

Upload your drawing for a 24-hour review and see how fast controlled finishing restores your schedule.

What Should You Demand from Your Supplier Right Now?

When communication stalls, stop accepting reassurances—demand proof.

Vague replies like “finishing soon” or “awaiting inspection” usually mean nobody has checked the job in days. Every 24 hours without verification shrinks your ability to recover the schedule.

The fastest way to expose stalled work is to ask for evidence: timestamped milestones, inspection photos, and packaging confirmations. A professional supplier can send them within hours because the data already exists in their workflow. If they hesitate, the parts likely haven’t moved.

We maintain photographic and digital logs for every stage—machining, cleaning, coating, and inspection—so status can be shared instantly. This keeps customers informed without confrontation and gives both sides a factual basis for decisions.

Why this matters: waiting for verbal updates wastes escalation time. Once plating or coating queues fill, missed windows can add entire weeks. Quick proof requests reveal whether a project is moving or frozen.

Supplier Takeaway:

Don’t settle for “it’s progressing.” Ask for photos, timestamps, or inspection sheets. If they can’t produce them, progress isn’t real. Suppliers that track every step can show proof before you need to ask.

What Quote Red Flags Predict Finishing Disasters?

If your quote lists machining lead time but ignores finishing, you’re looking at a built-in delay.

That single omission—no anodizing days, no inspection hours—means the supplier hasn’t reserved finishing capacity. What follows is the classic “machining complete, still in finishing” loop.

Common red flags hide in plain sight. Watch for:

- Separate pricing for anodizing without a stated turnaround

- “To be confirmed” under coating type or color

- Missing inspection or packaging references

- Lead time rounded to the nearest week instead of specific days

These signals mean finishing will be arranged after machining, not planned in parallel. Once your order reaches the finisher’s backlog, every revision, masking change, or rejected batch multiplies delays.

Our quoting process integrates finishing at the start. We confirm coating slots, inspection windows, and masking time before machining begins. Each operation’s duration is calculated from actual capacity—not averages—so lead times hold. When finishing is pre-booked, average delivery deviation drops from ±10 days to ±2.

Why this matters: the wrong quote doesn’t just misprice—it misrepresents risk. Early detection saves weeks later.

Supplier Takeaway:

If a quote can’t show where finishing fits in the schedule, it’s not under control. Demand explicit finishing days and inspection time before approving any PO. Missing data at the quote stage is the first sign of a future delay.

How Do You Protect Your Timeline in the Next PO?

You protect your next project by locking process control into the purchase order, not trusting after-the-fact updates.

Most timeline failures happen because POs specify price and quantity—but not how work must be sequenced or reported. Without built-in checkpoints, even reliable shops drift.

Include explicit requirements:

- Defined lead-time split (machining + finishing + inspection)

- Progress evidence every 48 hours or key-stage photos

- Approval for any subcontracted finishing before release

- Penalty or re-quote clause if finishing adds more than 3 days beyond plan

Suppliers resist these clauses only when they lack control. Those that operate integrated workflows accept them easily because they already track milestones. In our system, coating and inspection slots are scheduled with machining, creating predictable overlap that shortens total duration by roughly 20–25 % versus separate scheduling.

Why this matters: deadlines fail quietly during quoting, not delivery. A strong PO turns communication promises into contractual checkpoints.

Supplier Takeaway:

Don’t repeat the same wait-and-see pattern. Specify finishing schedules, progress proof, and escalation timelines directly in your PO. The best suppliers will agree without hesitation—the rest will expose their limits before production even begins.

Conclusion

Finishing delays expose when suppliers lose real process control—leaving your project idle after machining. We manage machining and finishing as one continuous workflow, keeping schedules intact and communication transparent. Upload your rejected or delayed drawings

Frequently Asked Questions

Yes, as long as we can inspect dimensional stability and surface condition. We measure all critical features, strip coatings if required, and re-enter the parts into our controlled finishing line. Most recovery projects resume within 48 hours once the physical samples arrive.

Ask for process photos, in-house inspection setups, or their finisher’s certification. Genuine control shows up as consistent lighting, part IDs, and same-day inspection stamps. If they can’t prove where coating happens, it’s probably outsourced — and that’s where timelines slip.

Request timestamped photos showing parts in racking, coating, and drying stages. Visual confirmation every 24–48 hours proves continuous movement. Suppliers who hesitate or send reused images rarely have physical possession of your job — that’s your cue to escalate or switch immediately.

Often yes. Minor anodizing stains or uneven coating can be stripped and re-finished if the base material meets dimensional tolerance. We assess part integrity first, then restore surfaces without altering geometry. Upload clear photos for confirmation — recovery usually takes 2–3 days instead of a full remake.

Ask for a dimensional report listing key tolerances, coating thickness certification, and surface-finish records. These confirm that finishing met both drawing specs and coating standards (e.g., MIL-A-8625). Getting reports before payment ensures issues are caught early and prevents rework delays later.

Because not all shops control the same stages. Some include subcontracted finishing, shipping, or masking rework; others don’t. A complete quote covers machining, coating, inspection, and packaging — fragmented quotes hide time and cost gaps that cause “unexpected” delays.