Designing aluminum parts for CNC machining requires balancing performance requirements with manufacturing realities. One seemingly minor design decision—like specifying unnecessarily tight tolerances or overlooking thermal expansion—can double your machining costs or cause production delays. With over 15 years of precision CNC experience across aerospace, medical, and audio applications, we’ve seen how small design adjustments dramatically improve both part quality and cost-effectiveness.

Smart aluminum CNC design starts with selecting the right grade (6061 for general use, 7075 for strength), specifying achievable tolerances (±0.05mm standard, ±0.01mm for critical features), and avoiding problematic geometry like thin walls or deep pockets that cause tool deflection and warping.

Find the best aluminum grades for your application, balance tolerances with cost, and avoid machining issues—backed by real audio, medical, and aerospace runs.

Table of Contents

Which Aluminum Grade Should I Choose for CNC Machining?

For most CNC projects, choose 6061-T6 aluminum. It offers the best balance of machinability, strength (310 MPa), and cost. Use 7075-T6 when you need high strength (572 MPa) for structural parts, or 2024-T4 for aerospace applications requiring fatigue resistance.

Quick Decision Guide:

- General enclosures, brackets, prototypes → 6061-T6

- High-stress components, structural parts → 7075-T6

- Aerospace, certified applications → 2024-T4

In our experience machining thousands of aluminum parts, 6061-T6 consistently delivers the best balance of workability and performance. It machines cleanly with minimal tool wear, produces excellent surface finishes (Ra 1.6-3.2 μm as-machined), and handles complex geometries without excessive chatter or deflection. We routinely hold ±0.01mm tolerances on 6061 parts using standard tooling and setups. Most importantly, 6061 is readily available in common sheet and bar sizes, typically shipping within 2-3 days.

For audio enclosures and medical housings, 6061 provides sufficient strength while anodizing beautifully with consistent color matching. However, when we manufactured mountain bike components and drone frames, 6061 showed stress cracking under high cyclic loads—that’s where 7075 became necessary.

7075-T6 offers nearly double the strength but costs 40% more in material and machining time. It requires thicker wall sections (minimum 2mm vs 1mm for 6061) to prevent warping and is more challenging to anodize consistently.

Design Takeaway: Start with 6061-T6 for 80% of applications. Upgrade to 7075-T6 only when load analysis shows 6061 won’t handle your stress requirements, and specify 2024-T4 exclusively for aerospace compliance.

What Tolerances Can I Specify Without Driving Up CNC Costs?

For most aluminum CNC parts, specify ±0.05mm for non-critical dimensions to keep costs reasonable. Reserve ±0.01mm tolerances only for critical features like bearing fits or mating surfaces. Tighter tolerances than ±0.005mm require specialized setups and can double machining costs.

Tolerance Decision Guide:

- Cosmetic surfaces, general edges → ±0.1mm

- Mounting holes, non-critical features → ±0.05mm

- Bearing bores, mating surfaces → ±0.01mm

- Precision fits, sealing surfaces → ±0.005mm

We routinely achieve ±0.01mm on aluminum parts using standard 3-axis mills with proper fixturing and temperature control. To put this in perspective, ±0.01mm is roughly the thickness of a human hair, while ±0.05mm equals about half the thickness of standard copy paper. These tolerances work for 90% of functional requirements without cost penalties.

For aluminum enclosures and brackets, ±0.05mm works perfectly for mounting holes and general geometry. Critical assembly features like shaft bores need ±0.01mm for proper fits, while sealing surfaces in medical housings may require ±0.005mm to prevent leakage. We’ve seen projects where over-specifying ±0.01mm tolerances on cosmetic features added significant inspection time and costs with zero functional benefit.

Tighter tolerances require additional inspection time with CMM measurement, temperature-controlled environments, and often secondary machining operations. Each tolerance grade tighter than ±0.05mm typically adds 15-25% to machining time due to slower feeds, additional passes, and verification requirements.

According to ISO 2768-m standards, medium tolerance grades provide adequate precision for most applications while maintaining cost efficiency.

Design Takeaway: Use ±0.05mm as your default tolerance and apply ±0.01mm only to features requiring precise fits—bearing bores, threaded holes, or assembly interfaces. Reserve ±0.005mm for truly critical applications where function depends on extreme precision.

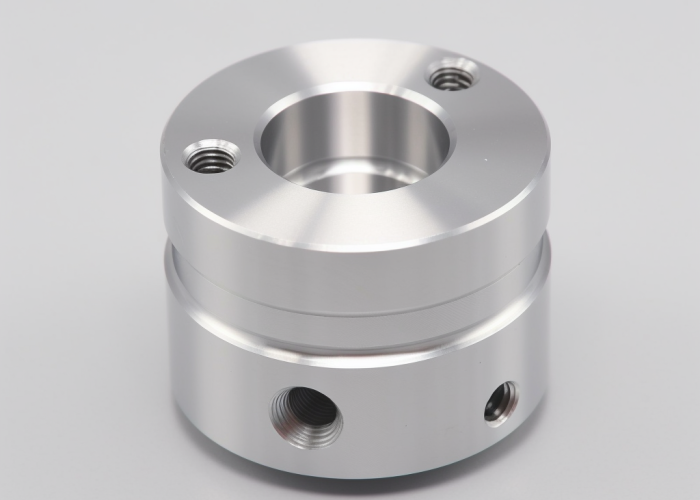

What CNC Limitations Should I Know When Designing Aluminum Parts?

Avoid thin walls under 1mm, deep pockets with length-to-width ratios over 4:1, and sharp internal corners under 0.5mm radius. These features cause tool deflection, chatter, and require specialized tooling that increases machining time significantly.

Design Guidelines for Cost-Effective Machining:

- Minimum wall thickness: 1.5mm (0.8mm absolute minimum)

- Internal corner radius: 0.5mm minimum, 1mm preferred

- Pocket depth-to-width ratio: Maximum 3:1

- Tool access clearance: 6mm minimum for standard tooling

Tool access drives most CNC limitations. Standard end mills need adequate clearance to reach features without deflection. When tools extend more than 6x their diameter from the spindle, they vibrate and create poor surface finishes. For example, machining a 10mm deep, 2mm wide slot requires a long, thin tool that’s prone to breakage and chatter.

Instead of designing problematic deep pockets, consider splitting the part into two pieces or redesigning with accessible geometry. Rather than sharp internal corners that require tiny end mills, specify 0.5-1mm radii that allow robust tooling. For parts requiring undercuts, evaluate whether split assemblies or secondary EDM operations are more cost-effective than complex 5-axis work.

Multiple setups dramatically increase costs due to refixturing time, alignment verification, and additional inspection requirements. Parts requiring complex geometry often benefit from design modifications that enable single-setup machining—even if it means adding fasteners or changing the assembly approach.

Threaded holes deeper than 2.5x diameter become challenging due to chip evacuation issues and increased tap breakage risk, especially in aluminum which can gall during threading.

Design Takeaway: Design for single-setup machining when possible. Add generous corner radii, maintain adequate wall thickness, and consider assembly alternatives to complex single-piece geometries. W

Will My Aluminum Part Warp During CNC Machining?

Thin-walled aluminum parts (under 2mm) and parts with large material removal are prone to warping due to stress relief. Parts with length-to-thickness ratios over 10:1 or asymmetric geometry have the highest warping risk and require specialized fixturing techniques.

Warp Prevention Design Rules:

- Maintain 3mm minimum wall thickness for parts over 100mm long

- Add structural ribs every 50mm on long, thin sections

- Design symmetric cutouts to balance internal stresses

- Specify 6061-T651 (stress-relieved) instead of 6061-T6 when available

We regularly see aluminum parts warp during cutting due to residual stresses in raw material. Rolled 6061-T6 plate contains manufacturing stress that redistributes when you remove material. We’ve measured 300mm long, 3mm thick plates bow up to 2mm after machining large pockets—enough to exceed most assembly tolerances.

Instead of designing thin walls, add reinforcing ribs or increase thickness strategically. A 200mm faceplate that warped at 2mm thickness stayed flat when redesigned with 3mm walls and two 5mm ribs. Material cost increased $8 per part but eliminated $25 flattening operations.

Starting with stress-relieved material (6061-T651) reduces warping significantly but costs 15-20% more. For unavoidable thin walls, vacuum fixturing and stress-relief heat treatment add 40-60% to costs.

Design Takeaway: Design 3mm minimum walls for long parts, add ribs for support, and balance material removal symmetrically. When thin walls are required, specify stress-relieved material and budget for potential correction operations.

What Surface Finish Should I Specify for My Aluminum Part?

As-machined aluminum typically achieves Ra 1.6-3.2 μm surface finish, suitable for most applications. Specify Ra 0.8 μm for sealing surfaces, and Ra 6.3 μm for hidden surfaces to reduce machining time by 30%.

Surface Finish Application Guide:

- Hidden surfaces → Ra 6.3 μm (saves 30% machining time)

- Visible cosmetic surfaces → Ra 1.6-3.2 μm (standard finish)

- Sealing surfaces, bearing contact → Ra 0.8 μm (adds 25% time)

Using sharp carbide tools, we consistently achieve Ra 1.6-3.2 μm on 6061 aluminum with standard parameters. This finish feels smooth to touch and anodizes beautifully for audio faceplates and medical enclosures.

For O-ring sealing surfaces, Ra 0.8 μm provides better sealing performance but adds 25% to machining time. For hidden brackets, Ra 6.3 μm works fine and reduces machining time significantly.

Avoid over-specifying finish. Ra 6.3 μm shows tool marks but works for internal surfaces. Ra 0.4 μm requires hand polishing that can triple costs—reserve for premium applications only.

Most shops don’t measure Ra unless you specify inspection requirements and pay for profilometer verification.

Design Takeaway: Use Ra 1.6-3.2 μm for visible surfaces and Ra 6.3 μm for hidden areas. Reserve Ra 0.8 μm for functional sealing surfaces, and specify inspection only when surface quality affects function.

How Does Anodizing Affect My Aluminum Part Dimensions?

Anodizing adds 12.5-25 μm (0.0125-0.025mm) to each surface, growing outward from the base material. For precision assemblies, reduce critical dimensions by half the anodizing thickness before machining. Type II anodizing adds ~12.5 μm per surface, while Type III hard anodizing adds ~25 μm per surface.

Anodizing Type Selection:

- Type II (decorative) → 12.5 μm buildup, available in colors, $8-12 per part

- Type III (hard coat) → 25 μm buildup, black/clear only, $15-20 per part

- Skip anodizing on → Threaded fastener holes, electrical contacts, press-fit surfaces

We regularly machine parts 0.025mm undersized on critical dimensions before Type II anodizing to maintain proper fits. For assemblies with ±0.05mm tolerance budgets, anodizing consumes half your available tolerance, requiring careful planning during design.

Drawing Callout Examples:

- Specify: “Ø10.000 +0.025/-0.000 AFTER ANODIZING”

- Or: “Ø9.975 ±0.01 BEFORE ANODIZING, Ø10.000 TARGET AFTER”

- Note: “MASK THREADS M6x1.0 FROM ANODIZING”

For threaded holes, we typically drill and tap 0.02mm oversize before anodizing, then mask threads to prevent coating buildup. Anodized threads bind and strip easily, so most designers specify masking for all threaded features.

Housing assemblies require special attention. If tolerance stack-up analysis shows anodizing will cause interference fits, consider design alternatives like split assemblies or selective anodizing of non-critical surfaces only.

6061 aluminum anodizes more consistently than 7075, with better color matching. Type III on 7075 can vary ±5 μm, making precision fits challenging.

Pre-machining dimensional adjustments typically add 10-15% to machining costs due to tighter tolerances and additional setup considerations.

Design Takeaway: Plan anodizing during design phase, not as afterthought. Specify critical dimensions “after anodizing” on drawings, mask threaded features, and account for anodizing thickness in your tolerance budgets to avoid assembly issues.

How Many Aluminum Parts Should I Order for Prototyping?

Order 3-5 prototype parts minimum to account for design iterations, testing damage, and assembly trials. For complex parts or new designs, order 5-10 pieces. Production pricing becomes cost-effective at 25+ pieces due to setup cost amortization.

Quantity Planning by Purpose:

- Fit and assembly testing → 3-5 pieces minimum

- Functional/stress testing → 5-10 pieces (includes destructive testing)

- First-time complex geometry → Order 50% extra for learning curve

- Production transition → 25+ pieces for cost efficiency

Typical Cost Progression (Example: Simple Bracket):

- 1 piece = $180 each

- 5 pieces = $75 each

- 25 pieces = $35 each

- 100 pieces = $22 each

Setup costs get distributed across quantity, making small runs expensive per piece. For prototypes, expect to pay 2-3x your target production piece price. However, the extra cost is minimal compared to 2-week delays from insufficient parts during critical testing phases.

For parts requiring stress testing or fatigue analysis, order enough for complete test protocols plus spares. Destructive testing typically requires 3-5 samples minimum for statistical validity, while fit testing needs 2-3 assemblies to verify tolerances and clearances.

Consider your project timeline when planning quantities. Prototype machining typically takes 5-10 business days, while production runs requiring material procurement may need 2-3 weeks. Order prototypes 2 weeks before your planned testing dates to avoid schedule delays.

Budget Planning Reality: If your target production cost is $30 per part, budget $75-90 each for initial prototypes, then transition to production pricing once design is validated.

Design Takeaway: Always order more prototypes than immediate testing needs require. The marginal cost increase is insignificant compared to project delays from parts shortage, and extra pieces enable thorough validation and rapid design iteration.

Conclusion

Smart aluminum CNC design starts with material selection, realistic tolerances, and manufacturability awareness. Avoid thin walls, plan for anodizing thickness, and order adequate prototypes for thorough testing. These decisions directly impact both part quality and project costs.

Contact us to explore aluminum CNC manufacturing solutions tailored to your product requirements.

Frequently Asked Questions

Threading after anodizing is not recommended as it removes the protective coating and creates weak points. Always machine threads before anodizing and mask them during the anodizing process to prevent coating buildup that causes binding or difficult assembly.

Order 3-5 prototypes for basic fit and function testing, or 5-10 pieces for complex parts requiring stress testing. Having extras prevents project delays when parts break during testing or design changes are needed.

As-machined Ra 1.6-3.2 μm works well before anodizing since the process improves surface appearance. Avoid over-specifying machined finish (like Ra 0.8 μm) before anodizing as it wastes money. The anodizing process will provide the final cosmetic quality.

Maintain minimum 3mm wall thickness for parts over 100mm long, add structural ribs every 50mm, and design symmetric material removal. Consider specifying 6061-T651 (stress-relieved) material instead of standard 6061-T6 to reduce internal stresses that cause warping.

±0.01mm is achievable on most aluminum parts without major cost increases using standard setups. Going tighter than ±0.005mm requires specialized equipment and can double machining costs. Reserve ultra-tight tolerances for truly critical features like bearing bores or precision fits.

6061-T6 offers excellent machinability, moderate strength (310 MPa), and costs less to machine due to reduced tool wear. 7075-T6 provides nearly double the strength (572 MPa) but costs 40% more in material and machining time. Choose 6061 for general applications and 7075 only when high strength justifies the extra cost.